Device and method for reducing nitrogen oxide generated by coke oven

A nitrogen oxide and coke oven technology, applied in the heating of coke oven, coke oven, coke oven parts, etc., can solve the problems of unchangeable coke oven structure, nitrogen oxide emission, etc. Emission reduction, effect of changing combustion flame length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

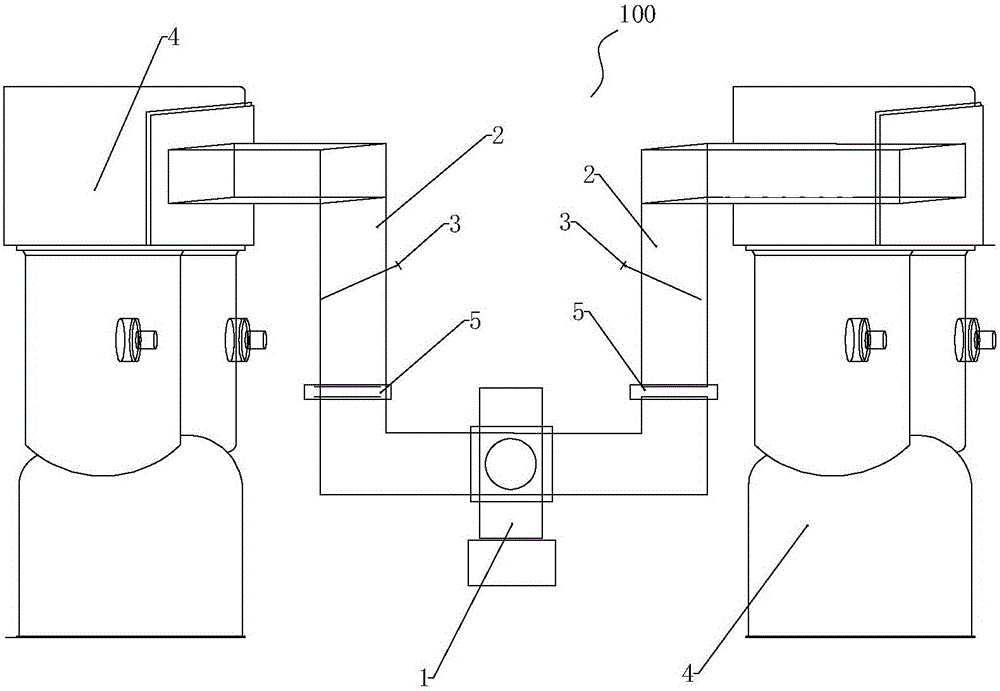

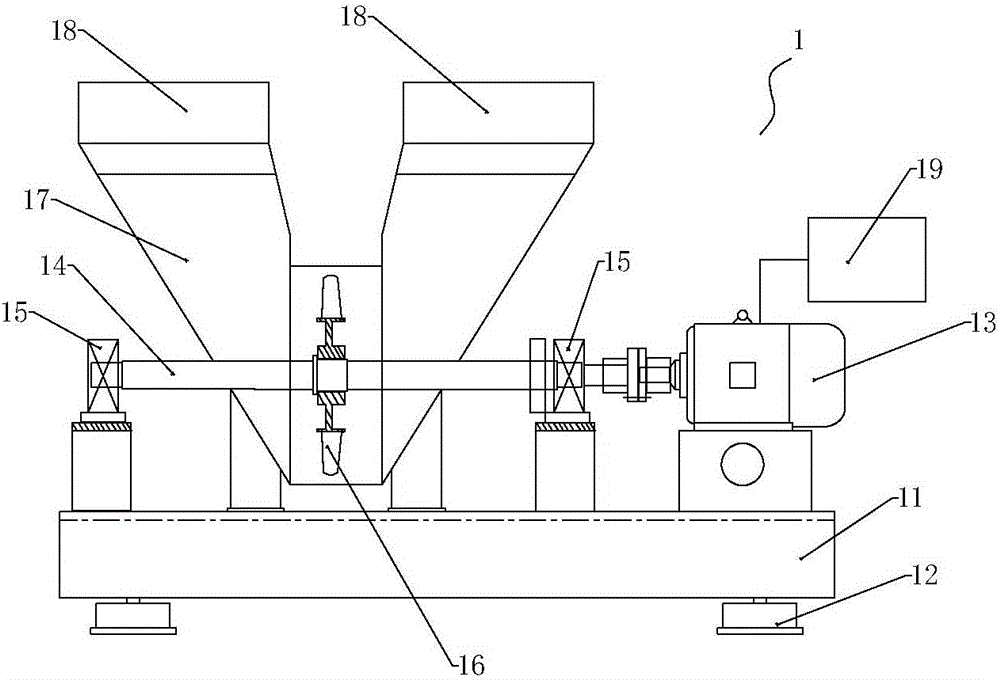

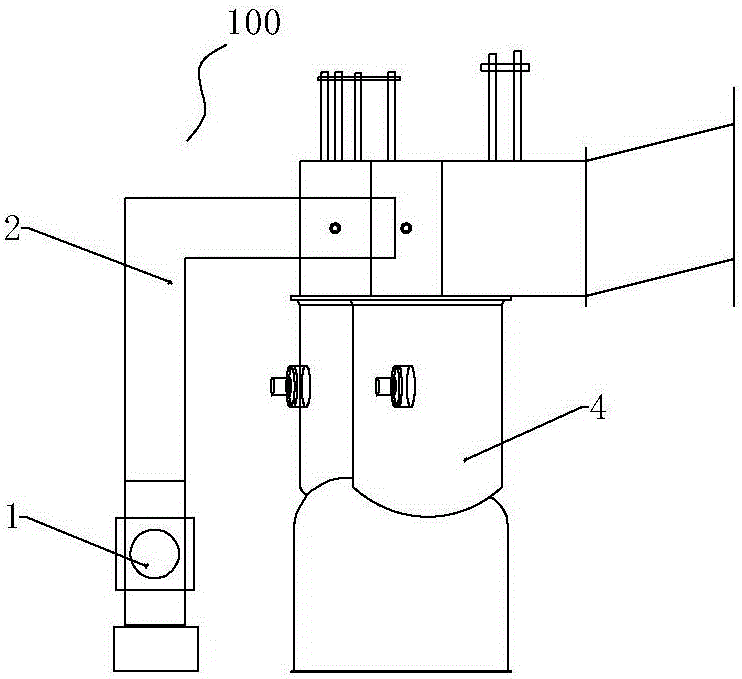

[0041] Embodiment 1: A tuyere 18 of the bidirectional axial flow fan 1 is connected to the oven hole at the end of the coke oven basement machine side or the coke side flue through the pipe 2 to take exhaust gas. The other tuyere 18 of the two-way axial flow fan 1 communicates with the side cover of the exchange switch 4 of the coke oven through the pipe 2, and the exhaust gas is sent into the updraft of the exchange switch 4 to mix with the air. The oven bakes the cold coke oven, and the masonry is dried, dehydrated and heated up to prepare for the transition of the coke oven to the production state. In this embodiment, it is relatively convenient to take exhaust gas from the existing oven hole.

Embodiment 2

[0042] Embodiment 2: A tuyere 18 of the two-way axial flow fan 1 is connected to the oven hole at the end of the sub-flue of the coke oven basement or the side of the coke oven and the flap of the sub-flue through the pipe 2, and the waste gas is taken from two places at the same time. exhaust gas. The other tuyere 18 of the two-way axial flow fan 1 communicates with the side cover of the exchange switch 4 of the coke oven through the pipe 2, and the exhaust gas is sent into the updraft of the exchange switch 4 to mix with the air. When the coke oven production load is adjusted, both gas and air consumption need to be adjusted. At this time, it is necessary to adjust the suction of the branch flue, that is, to adjust the opening of the branch flue flap. This embodiment is to get exhaust gas supply exchange switch 4 updraft from branch flue two ends (oven hole and branch flue flap place).

Embodiment 3

[0043] Embodiment 3: A tuyere 18 of the two-way axial flow fan 1 is connected to a branch flue at the lower end of an exchange switch 4 on the coke oven machine side or the coke side through the pipe 2 to take exhaust gas. The other tuyere 18 of the two-way axial flow fan 1 communicates with the side covers of the other exchange switches 4 on both sides of the exchange switch 4 through the pipe 2 . This exchanging switch 4 is a descending airflow, and the other exchanging switches 4 on both sides are an ascending airflow, and waste gas is sent to the ascending airflow of other exchanging switches 4 on both sides. During the implementation of this embodiment, because the gas is taken from the sub-flue below a certain exchange switch 4, the amount of gas taken is relatively large, and it can be used by a plurality of exchange switches 4 that are in the updraft, and can be supplied according to the amount of waste gas taken. 3 to 5 replacement switches 4 are used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com