Method for preparation of raw materials for smelting calcium carbide

A technology of raw materials and calcium carbide, which is applied in the field of preparing calcium carbide smelting raw materials, and can solve problems such as poor quality of calcium carbide products, easy burning and overburning, and high calcium carbide smelting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

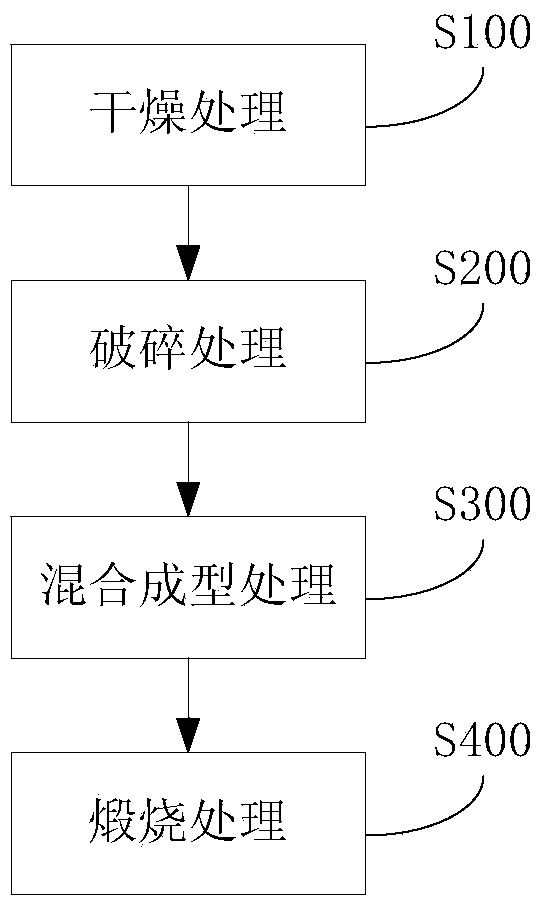

Method used

Image

Examples

preparation example Construction

[0040] According to the method for preparing calcium carbide smelting raw materials according to the embodiment of the present invention, the limestone is crushed to be below 3 mm, which effectively reduces the calcination temperature and reduces the calcination time;

[0041] According to the method for preparing calcium carbide smelting raw materials according to the embodiment of the present invention, the calcination process of limestone is combined with the pyrolysis process of raw coal, which improves the utilization rate of heat energy;

[0042] According to the method for preparing calcium carbide smelting raw materials according to the embodiment of the present invention, the calcination temperature distribution in the annular furnace is uniform, and the raw burning and over-burning rate of limestone are low;

[0043] According to the method for preparing calcium carbide smelting raw materials according to the embodiment of the present invention, the calcined quicklime...

Embodiment

[0048] raw material:

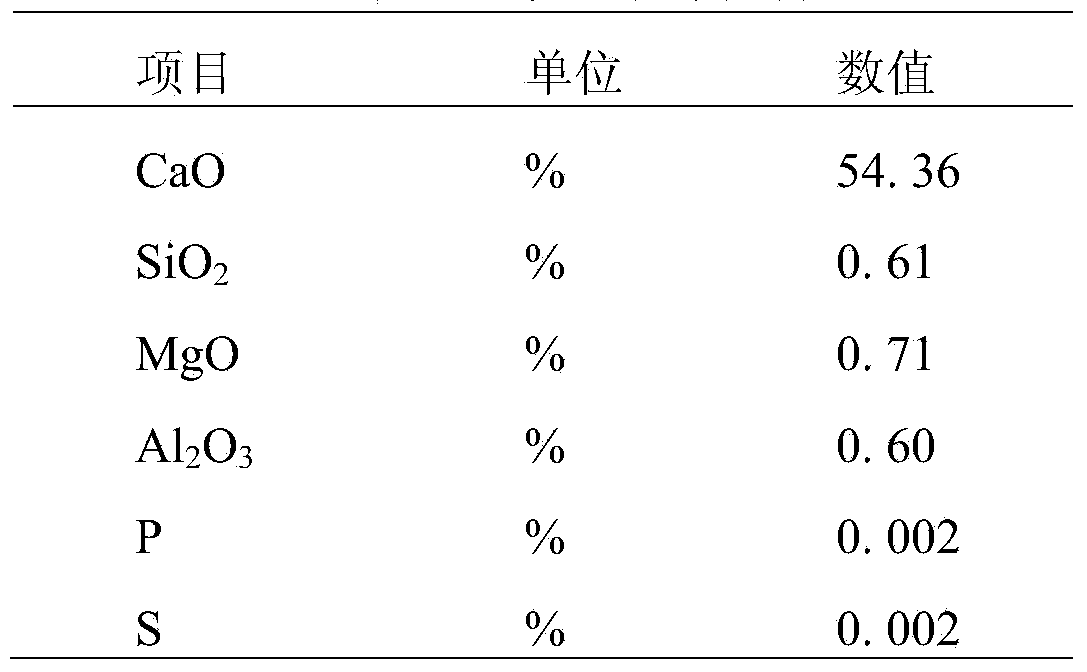

[0049] Limestone, the chemical composition of this limestone is shown in Table 1;

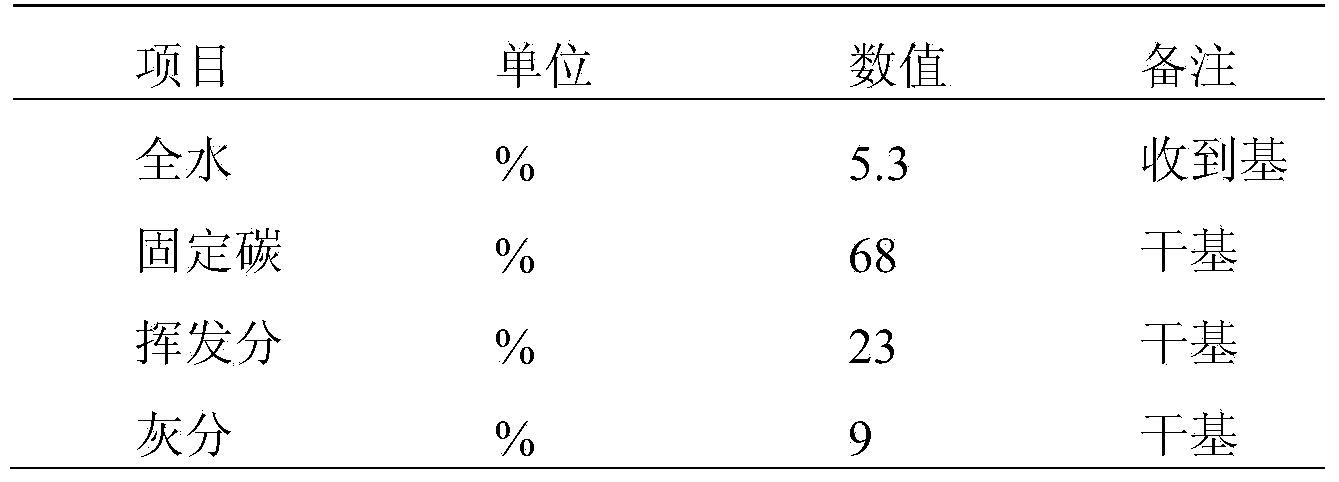

[0050] Long-flame coal, the main properties of this long-flame coal are shown in Table 2.

[0051] Table 1 Limestone chemical composition

[0052]

[0053] Table 2 Main properties of long-flame coal

[0054]

[0055] Preparation:

[0056] First, the long-flame coal is dried by an indirect tube-type drum drying device, the drying heat source is 0.8MPa saturated steam, and the moisture content of the long-flame coal after drying is 0.3%. The limestone and the dried long-flame coal are respectively crushed by a crusher, and the average particle size after crushing is 1-3 mm. Further, limestone particles and long-flame coal particles were mixed according to the mass ratio of 1:2.3 and then extruded to obtain a molding material with a particle size of 32×25×18 mm. The molding material was sent into the annular furnace, and the calcination process was carried out acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas output | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com