Explosion method of dimension stone production in joint development rock

A technology of specification and stone, which is applied in the field of blasting for the production of specification stone in rocks with developed joints, can solve the problems of difficulty in obtaining standard stone with uniform particle size, lack of pertinence in blasting methods, and differentiation of blasting methods, so as to meet the needs of use and be operable Strong, easy-to-step effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

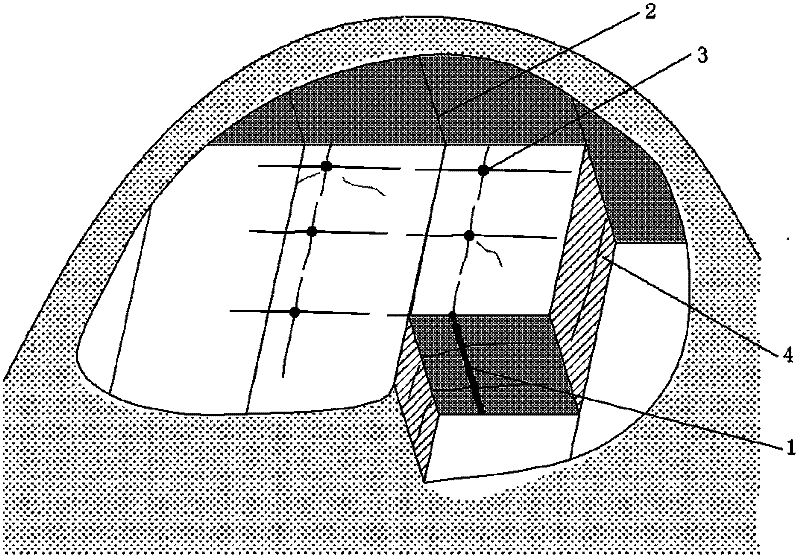

[0013] Such as figure 1 As shown, in the rock with well-developed joints, the interaction relationship between blasting damage cracks and rock joint surface 2 is that the damage cracks are mainly formed and distributed along the joint surface 2, or start from the wall of the blast hole 3 and develop perpendicular to the joint surface 2.

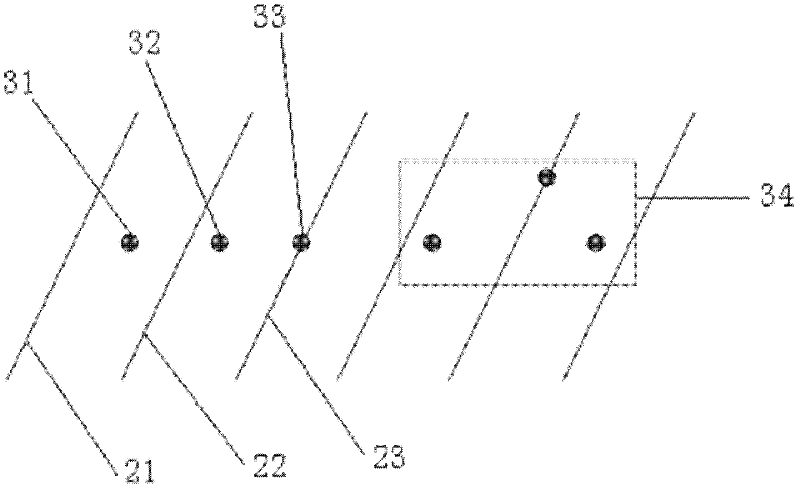

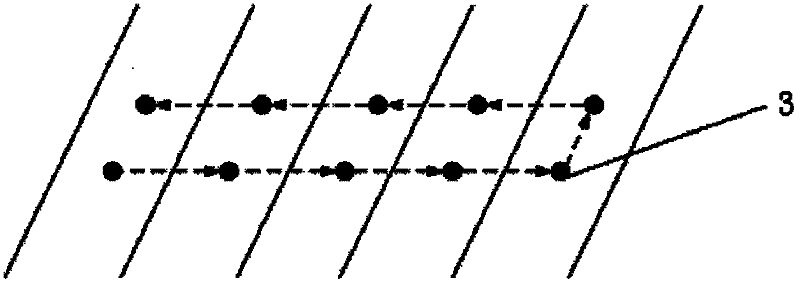

[0014] According to the interaction relationship between the blasting damage crack and the rock joint surface 2, first, the angle between the blast wave propagation direction and the joint surface 2 is controlled by adjusting the axial angle between the blast surface 4 and the blast hole 3, so as to constrain the direction of the blast crack; By adjusting the relative position of the charge column 1 and the joint surface 2, combining or selecting the hole layout method such that the blast holes 3 are located in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com