Heat exchange chamber of coke oven and coke oven

A coking oven and heat exchange chamber technology, applied in the field of coking, can solve problems such as unbalanced heating of coke ovens, self-sufficiency in heat, and influence on heat transfer effects, and achieve the goals of shortening coking time, fast heating speed, and improving heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

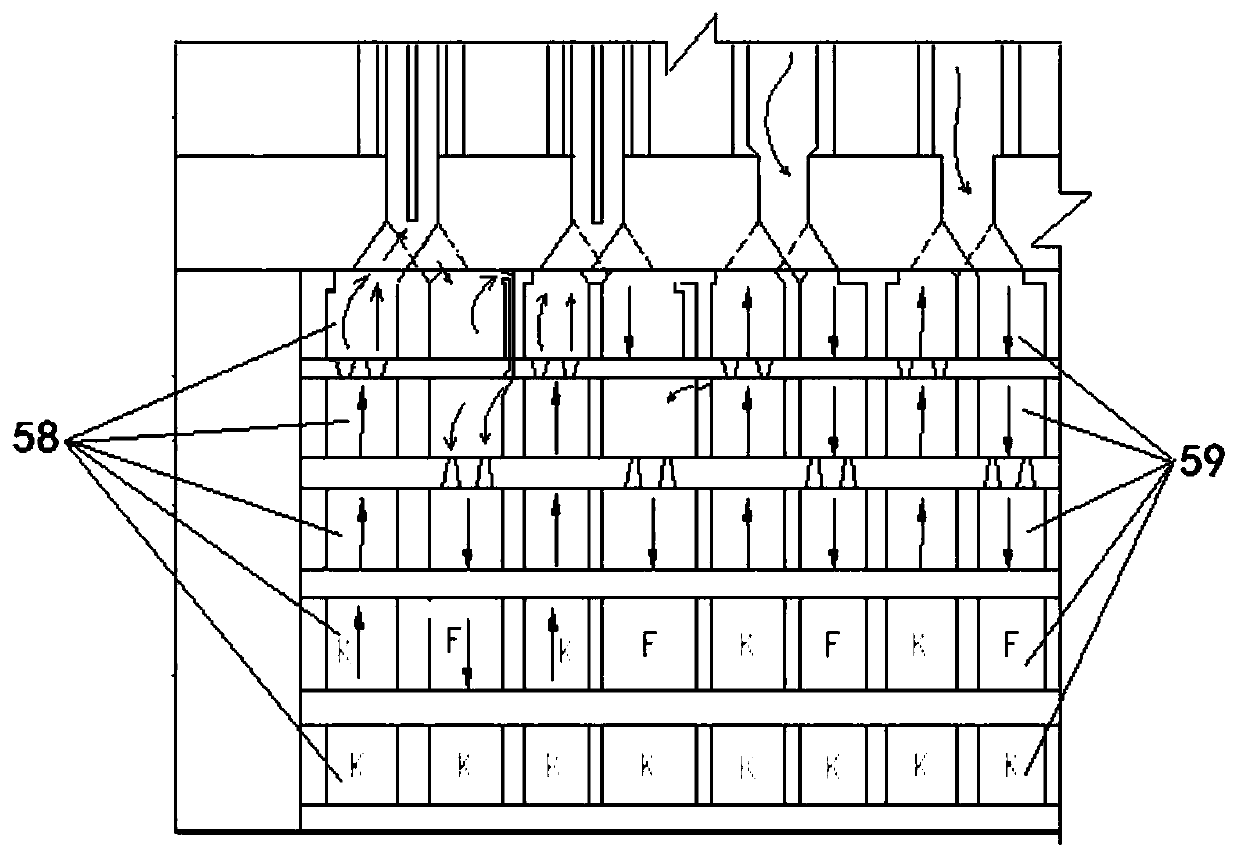

[0051] Such as figure 1 As shown, this embodiment discloses a heat exchange chamber for a coke oven, including a chamber body, the interior of the chamber body is a multi-layer structure, the interior of the chamber body is provided with an air passage 58 and a flue gas passage 59, the air passage 58 and the The flue gas channels 59 are arranged side by side and penetrated on the multi-layer structure at the same time, so that the layers of the multi-layer structure are connected in sequence, that is, each layer in the multi-layer structure has an air channel and a flue gas channel, and all The air passages of the layers are connected to form a whole row of air passages 58, and the smoke passages of all layers are connected to form a whole row of smoke passages 59, so that each layer of the multilayer structure has an air passage corresponding to the layer (which is A section of the whole row of air channels 58, hereinafter referred to as the air channel of the layer) and a sm...

Embodiment 2

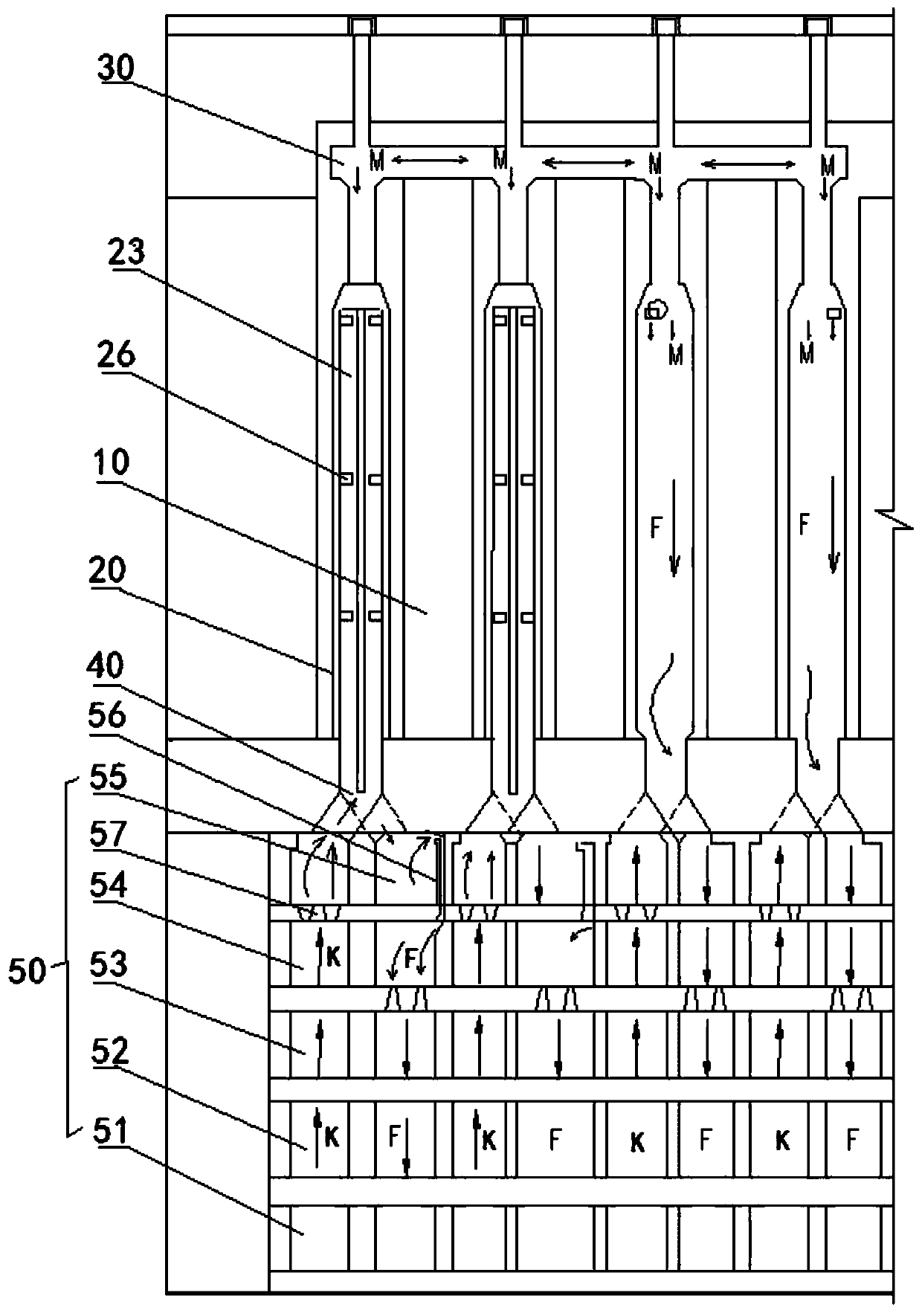

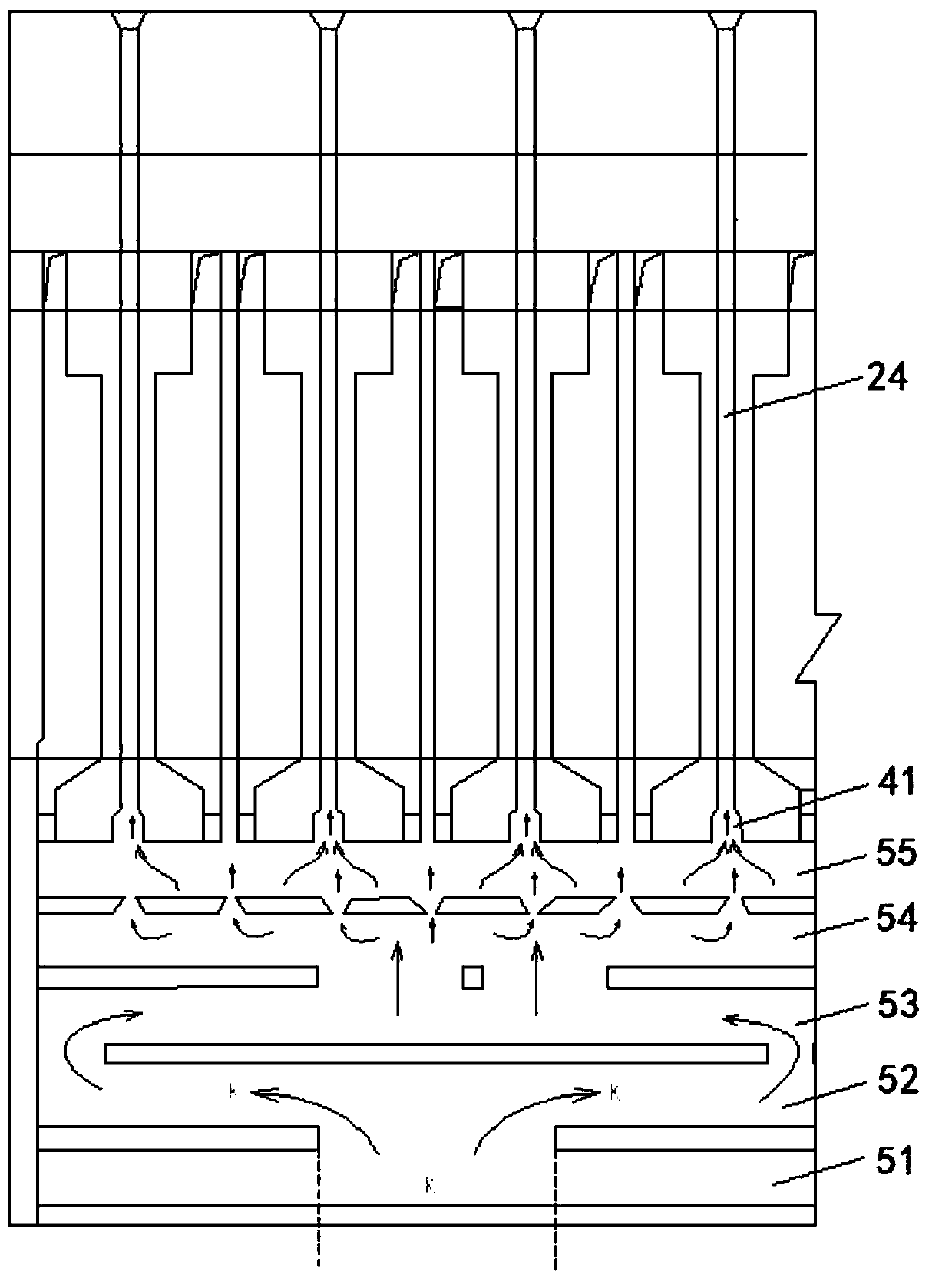

[0062] Such as figure 2 As shown, this embodiment discloses a coke oven, which includes a furnace body, which is provided with a carbonization chamber 10 and a combustion chamber 20, as well as the heat exchange chamber described in Embodiment 1. The carbonization chamber 10 and the combustion chamber 20 are arranged side by side on the upper part of the furnace body. The combustion chamber 20 includes a vertical fire passage 23 and an air passage 24. The carbonization chamber 10 communicates with the vertical fire passage 23. The heat exchange chamber 50 is located at the bottom of the furnace body. The air passage 58 communicates with the air passage 24 in the combustion chamber 20 , and its smoke passage 59 communicates with the vertical fire passage 23 in the combustion chamber 20 .

[0063] Optionally, the coke oven also includes a balance channel, which is arranged on the top of the carbonization chamber 10 and the combustion chamber 20, and communicates with the balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com