Cutting mechanism for multi-arm hob-type continuous tunneling machine

A roadheader and hob-type technology, which is applied to the cutting mechanism field of multi-arm hob-type continuous roadheaders, can solve the problems of inapplicability to hard rock roadways and low rock-breaking efficiency, so as to improve cutting efficiency and strengthen the breaking efficiency. Rock effect, the effect of increasing blockiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

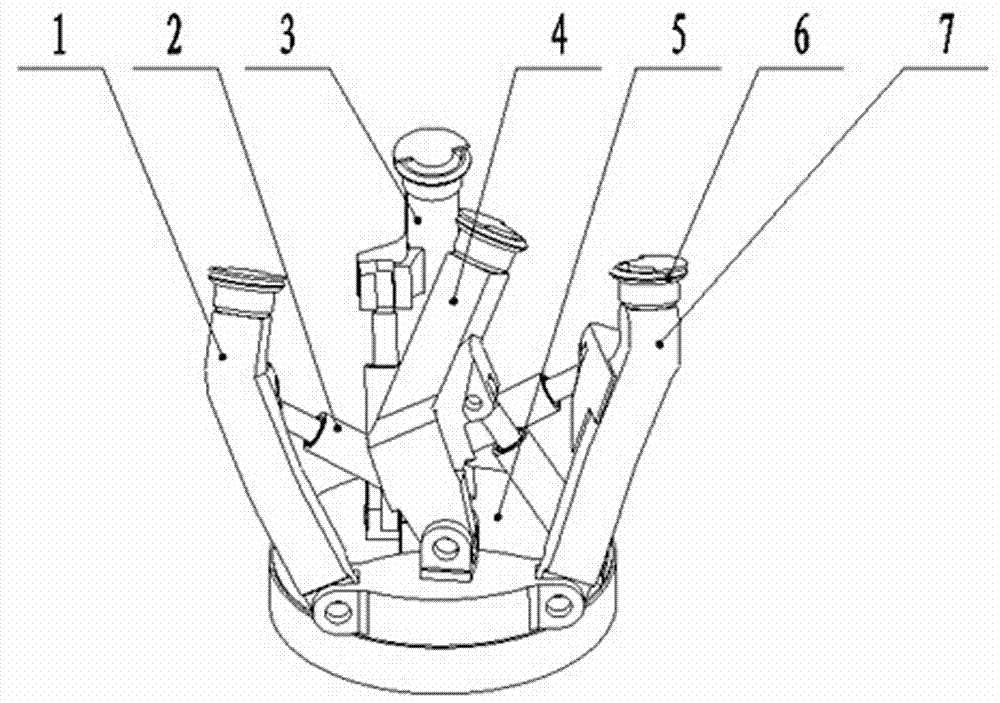

[0014] like figure 1 As shown, the cutting mechanism for the multi-arm hob type continuous roadheader is characterized in that it includes a slewing bearing 5, three outer rotating arms, an inner rotating arm 4, a disc hob 6 and a swing cylinder. The slewing bearing 5 includes an inner ring and an outer ring, the outer ring is fixed on the frame of the roadheader, the inner ring is installed and connected with the motor output shaft of the roadheader, and each outer rotating arm and inner rotating arm 4 are hinged on the inner ring through pin shafts , the hinge points of the three outer rotating arms and the inner ring are arranged in the circumferential direction of the inner ring and the distance from the hinge points of the three outer rotating arms and the inner ring to the center of rotation of the inner ring is equal, wherein the first outer rotating arm 1 and the second The two outer rotating arms 3 are symmetrically arranged at an angle of 180 degrees, the third oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com