Method for producing stone plate roasted meat and its stone plate roasting meat device

A production method and technology of slate, applied in the production field of slate barbecue equipment and slate barbecue, can solve the problems of small amount of barbecue, uneven heating, high fuel consumption, etc., achieve large amount of barbecue, reduce heat loss, save energy energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of production method of slate barbecue, barbecue lamb rib meat, has the following steps:

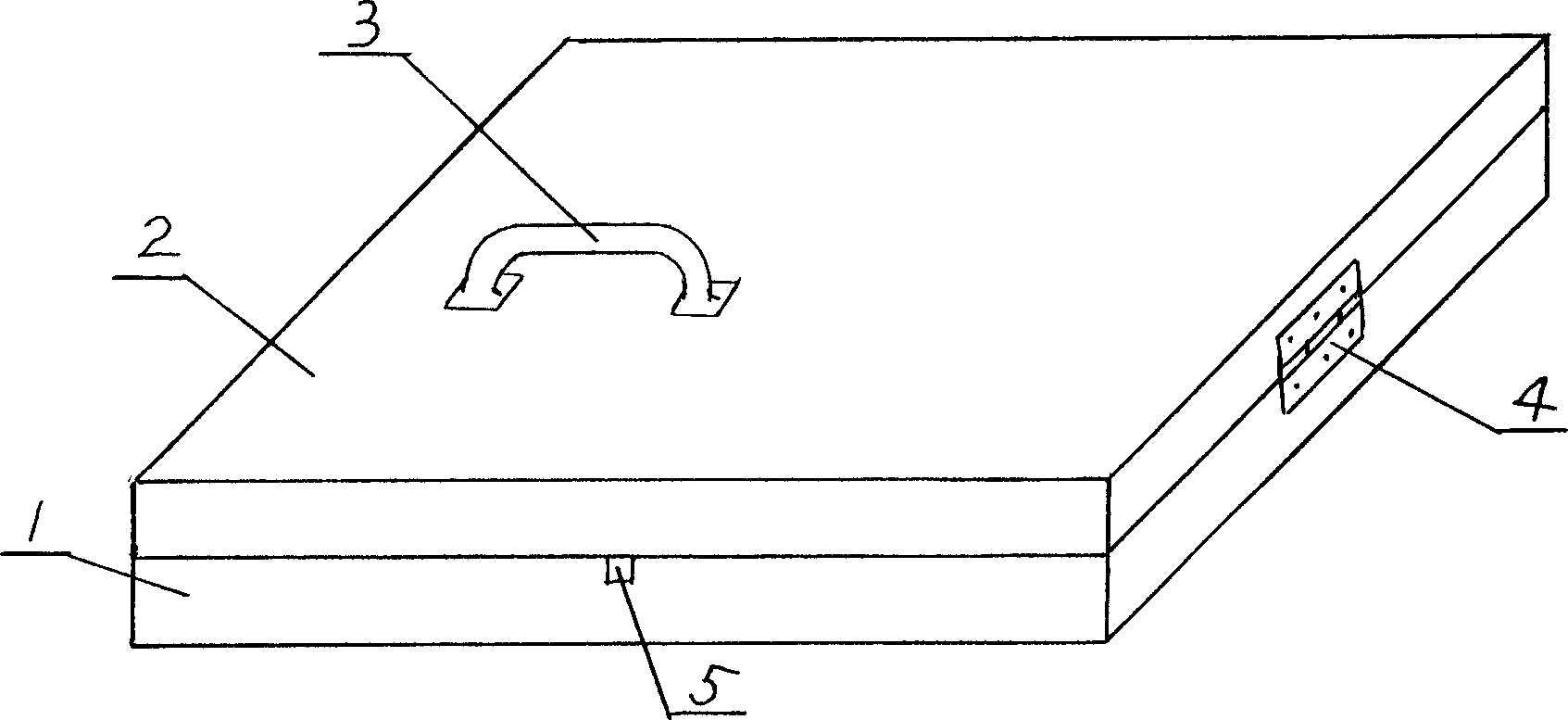

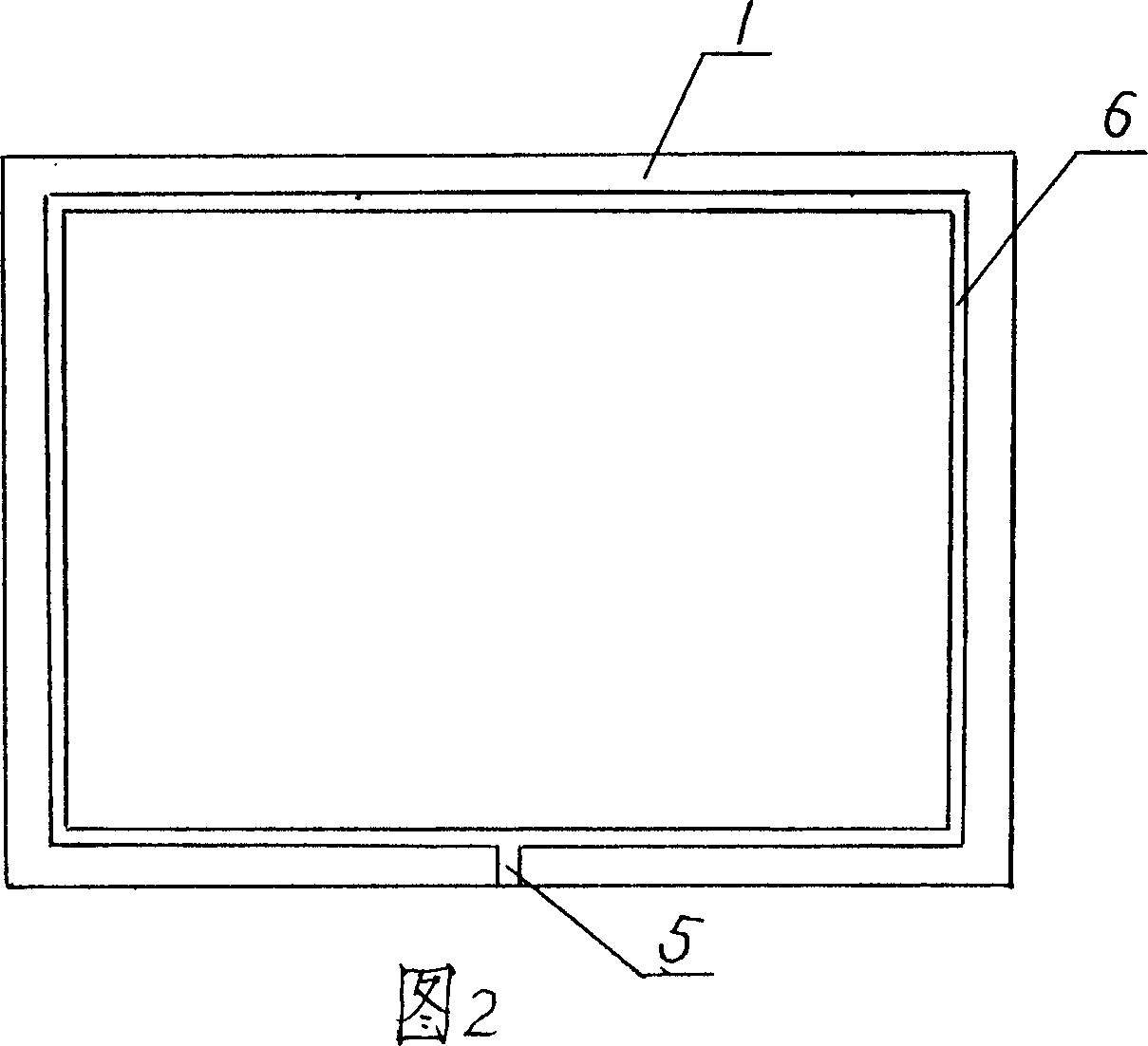

[0019] 1. Use the coal heating furnace below the barbecue stone 1 covered with the upper cover stone 2 to heat the barbecue stone 1 covered with the upper cover stone 2, so that the temperature on the upper surface of the barbecue stone 1 is always maintained at 250°C-300°C;

[0020] 2. Open the upper cover slate 2, apply mutton oil on the back of the upper cover slate 2 and the upper surface of the barbecue slate 1, and cut off each rib bone of the cut meat slices with ribs from the middle, and the meat slices are close to each other. One side of the rib bone is evenly spread on the upper surface of the meat roasting plate 1, covered with the upper cover stone plate 2, and roasted for 4-5 minutes;

[0021] 3. Open the upper cover stone plate 2, cut evenly distributed incisions on the meat slices perpendicular to the ribs with a knife, the distance between the incisions is ...

Embodiment 2

[0025] A kind of production method of slate barbecue, barbecue kebab, has the following steps:

[0026] 1. The heating furnace heats the barbecue stone 1 covered with the upper cover stone 2, so that the temperature on the upper surface of the barbecue stone 1 is always kept at 200°C-250°C;

[0027] 2. Open the upper cover slate 2, apply mutton oil on the back of the upper cover slate 2 and the upper surface of the barbecue slate 1, arrange 80 strings of lamb skewers evenly spread on the upper surface of the barbecue slate 1 Put it on, cover with the upper cover slate 2, and bake for 2 minutes;

[0028] 3. Open the upper cover slate 2, turn the mutton skewers laid on the upper surface of the barbecue slate 1 up and down 180°, then cover the upper cover slate 2 and stew for 1 minute;

[0029] 4. Open the upper cover slate 2, sprinkle an appropriate amount of salt on the mutton skewers, cover the upper cover slate 2, and roast for 1 minute, then open the upper cover slate 2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com