A method for preparing bulk graphene airgel

A graphene aerogel, graphene dispersion technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of increasing the production cost of graphene aerogel, harsh process conditions, complex preparation process, etc. , to achieve the effect of improving mechanical strength and compression performance, high mechanical strength, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

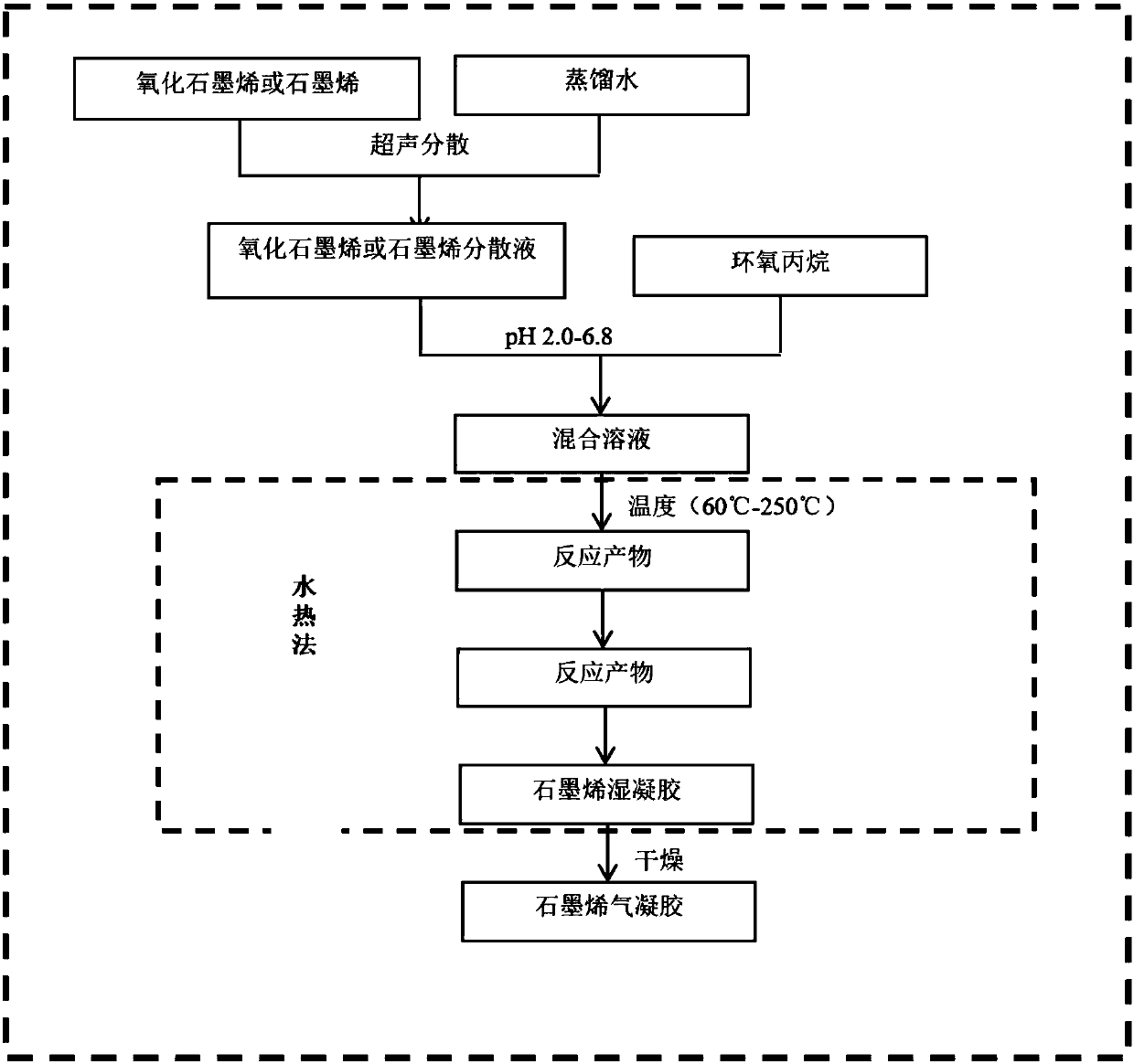

Method used

Image

Examples

Embodiment 1

[0022] Take 0.3g of prepared graphite oxide and add it to a beaker containing 100ml of distilled water, take it out after ultrasonication for 1.5h, cool to room temperature, and obtain a graphene oxide dispersion, add 60mL of propylene oxide PO at one time, and control its concentration by NaOH solution after stirring. The pH value is in the range of 2.0-6.8, then put the graphene oxide dispersion liquid added with propylene oxide into the reaction kettle, put it into the oven for reaction, first set the temperature to 60°C, and after 30 minutes of reaction, raise the temperature to 80°C, after 1 hour of reaction, raise the temperature to 250°C for 60 hours to obtain a wet gel, freeze-dry the wet gel at -50°C for 9 hours to obtain a product with high mechanical strength, good elasticity and a density as low as 0.19g / cm 3 ultralight graphene aerogels.

Embodiment 2

[0024] Take 0.5g of prepared graphite oxide and add it to a beaker filled with 100ml of distilled water, take it out after ultrasonication for 1.5h, cool to room temperature, and obtain a graphene oxide dispersion, add 10ml of propylene oxide PO at one time, and control its concentration by NaOH solution after stirring. The pH value is in the range of 2.0-6.8, then put the graphene oxide dispersion liquid added with propylene oxide into the reaction kettle, put it into the oven for reaction, first set the temperature to 60°C, and after 30 minutes of reaction, raise the temperature to After reacting for 1 hour at 80°C, the temperature was increased to 250°C for 6.5 hours to obtain a wet gel, and the wet gel was freeze-dried at -50°C for 9 hours to obtain a graphene airgel.

Embodiment 3

[0026] Take 0.5g of prepared graphite oxide and add it to a beaker filled with 100ml of distilled water, take it out after ultrasonication for 1.5h, cool to room temperature, and obtain a graphene oxide dispersion, add 100ml of propylene oxide PO at one time, and control its concentration by NaOH solution after stirring. The pH value is in the range of 2.0-6.8, then put the graphene oxide dispersion liquid added with propylene oxide into the reaction kettle, put it into the oven for reaction, first set the temperature to 60°C, and after 30 minutes of reaction, raise the temperature to After reacting for 1 hour at 80°C, the temperature was raised to 120°C for 18 hours to obtain a wet gel, and the wet gel was dried under normal pressure for 10 hours to obtain a graphene airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com