Closed ventilating and insulating pig breeding workshop

A closed, live pig technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of high power consumption, cause diseases, and unsatisfactory cooling effect, and achieve the effect of smooth ventilation and uniform room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

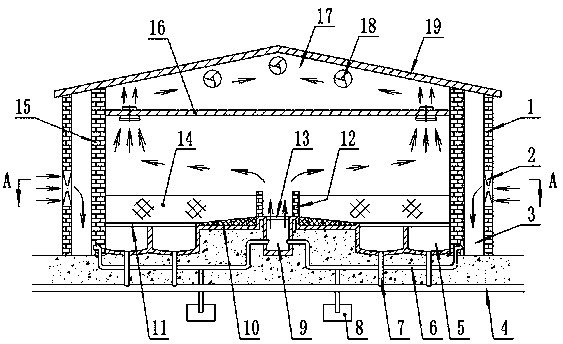

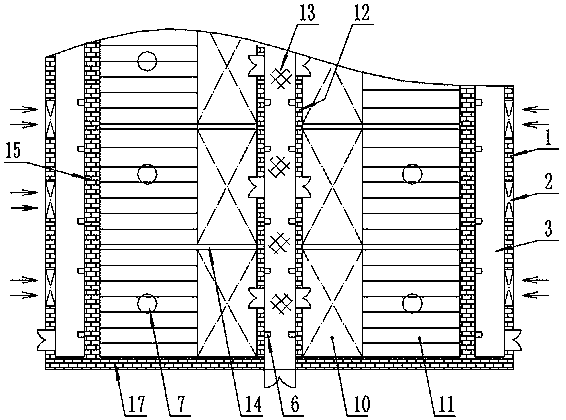

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

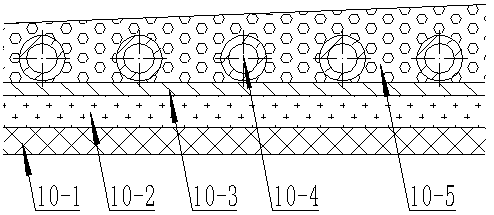

[0022] like Figure 1~4 As shown, the factory building is a closed structure, and the left side wall and the right side wall of the factory building are all interlayer channel 3 structures formed by an inner wall 15 and an outer wall 1 provided with a plurality of window holes. A wet curtain device 2 is fixed. There is a ventilation ditch 9 arranged along the direction of the mezzanine passage 3 in the center of the floor of the factory building, and several air ducts 6 buried underground communicate the ventilation ditch with the interlayer passages 3 located on both sides of the factory building. On the ceiling 16 of the factory building, a plurality of negative pressure fans 18 are fixed on the position near the inner walls 15 on both sides, and on the gable wall 17 between the ceiling and the roof 19 of the factory building.

[0023] The top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com