Heat insulation paint, preparation method of heat insulation paint and heat insulation coating thereof

A technology of thermal insulation coating and thermal insulation coating, applied in the direction of coating, can solve the problems of poor thermal insulation effect of thermal insulation coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

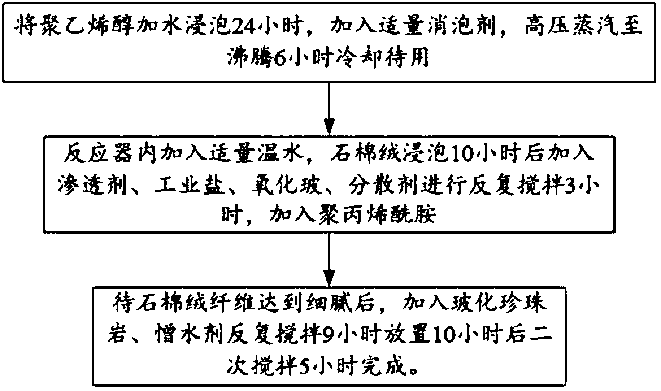

[0036] Such as figure 1 As shown, the embodiment of the present invention provides a preparation method of thermal insulation coating, which is a preparation method of the above thermal insulation coating, and the preparation method of the thermal insulation coating includes the following steps:

[0037] Step S110: Soak the polyvinyl alcohol in water for 24 hours, add an appropriate amount of defoamer, and steam under high pressure until it boils for 6 hours and cool for later use.

[0038] Step S120: add an appropriate amount of warm water into the reactor, soak the asbestos wool for 10 hours, add penetrant, industrial salt, glass oxide, and dispersant, stir repeatedly for 3 hours, and then add polyacrylamide.

[0039] Step S130: After the asbestos fiber becomes fine, add vitrified perlite and water repellent and stir repeatedly for 9 hours, let stand for 10 hours, and then stir again for 5 hours to complete.

[0040] The preparation method of the thermal insulation coating ...

Embodiment 1

[0043] Weigh the following components in parts by mass: 30 parts of asbestos wool, 80 parts of vitrified perlite, 0.8 part of foaming agent, 0.5 part of dispersant, 0.3 part of defoamer, 30 parts of zirconia, 20 parts of polyvinyl alcohol, 3 parts of water repellent, 2 parts of salt, 0.3 parts of pigment, 3 parts of whitening agent, 0.3 parts of polyacrylamide and 250 parts of water. Wherein, the antifoaming agent is silicone.

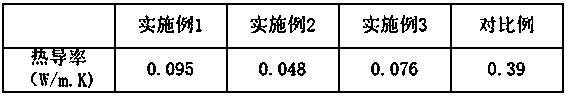

[0044] The thermal insulation coating of Example 1 was painted on the surface of the building with a coating thickness of 2 mm. After drying, a thermal insulation coating was formed. The thermal conductivity of the thermal insulation coating of Example 1 was tested by the EN12664 measurement method. Among them, the thermal conductivity directly reflects the thermal insulation effect of the thermal insulation coating. The thermal conductivity of the thermal insulation coating formed by the thermal insulation coating in Example 1 is shown in Table 1.

Embodiment 2

[0046] Weigh the following components in parts by mass: 50 parts of asbestos wool, 100 parts of vitrified perlite, 1 part of foaming agent, 0.8 part of dispersant, 0.5 part of defoamer, 38 parts of zirconia, 25 parts of polyvinyl alcohol, 3.3 parts of water repellent, 2.5 parts of salt, 0.5 parts of pigment, 3.5 parts of whitening agent, 0.5 parts of polyacrylamide and 300 parts of water. Wherein, the antifoaming agent is silicone.

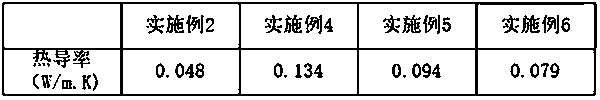

[0047] The thermal insulation coating of Example 2 was painted on the surface of the building with a coating thickness of 2 mm. After drying, a thermal insulation coating was formed. The thermal conductivity of the thermal insulation coating of Example 2 was tested by the EN12664 measurement method. Among them, the thermal conductivity directly reflects the thermal insulation effect of the thermal insulation coating. The thermal conductivity of the thermal insulation coating formed by preparing the thermal insulation coating in Example 2 is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com