Thermal insulation coating, preparation method thereof and thermal insulation coating

A technology for thermal insulation coatings and thermal insulation coatings, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor thermal insulation effect of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

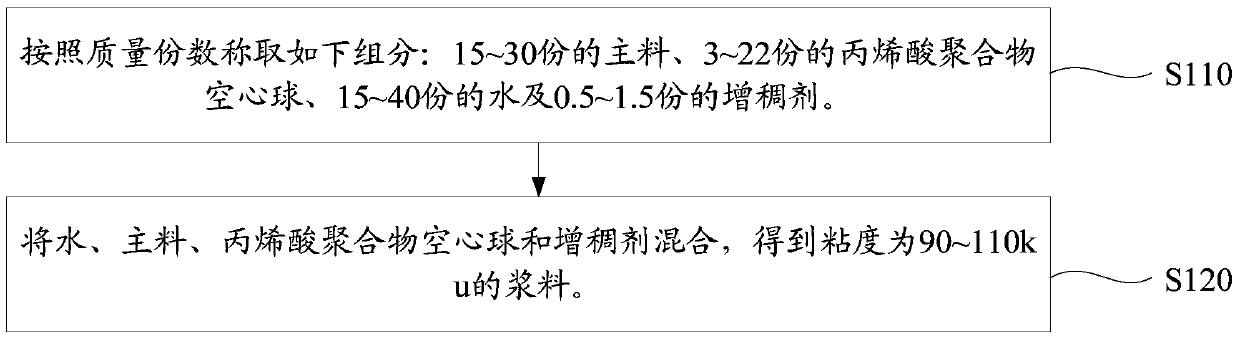

[0038] Such as figure 1 Shown, the preparation method of the thermal insulation coating of an embodiment is a kind of preparation method of above-mentioned thermal insulation coating, and the preparation method of this thermal insulation coating comprises the following steps:

[0039] Step S110: Weigh the following components in parts by mass: 15-30 parts of main ingredients, 3-22 parts of acrylic polymer hollow spheres, 15-40 parts of water and 0.5-1.5 parts of thickener.

[0040] Among them, the main material is a polymer resin with an elastic elongation of more than 800% and a glass transition temperature below -10°C.

[0041] Specifically, the main material is selected from one of water-based acrylic resin and water-based polyurethane resin. Wherein, the acrylic resin may be Primac HA-8 of BASF, Germany. , the water-based polyurethane resin can be German Bayer water-based polyurethane emulsion DISPERCOLL U54.

[0042] Wherein, the acrylic polymer hollow sphere is a copo...

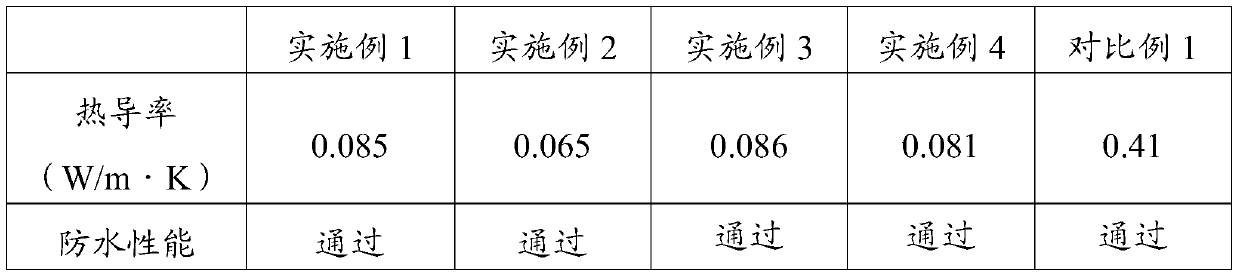

Embodiment 1

[0055] The preparation process of the thermal insulation coating of the present embodiment is as follows:

[0056] Weigh the following components in parts by mass: 25 parts of main material, 13 parts of acrylic polymer hollow spheres, 30 parts of water, 1 part of thickener, 5 parts of pigment, 15 parts of filler, 0.5 parts of dispersant, 1 part of defoamer, 1.5 parts of propylene glycol and 0.2 parts of preservative. Among them, the main material is water-based acrylic resin, with an elastic elongation of 800% and a glass transition temperature of -10°C; the acrylic polymer hollow spheres are copolymer hollow spheres of methyl methacrylate and butyl acrylate, with a particle size of 40 micron; the thickener is methyl cellulose; the preservative is isothiazolinone; the defoamer is mineral oil; the filler is kaolin; and the pigment is titanium dioxide powder.

[0057] Disperse and mix water, dispersant, propylene glycol, pigment and filler in a disperser at 1500 rpm, add defoam...

Embodiment 2

[0062] The preparation process of the thermal insulation coating of the present embodiment is as follows:

[0063] Weigh the following components in parts by mass: 15 parts of main material, 22 parts of acrylic polymer hollow spheres, 40 parts of water, 0.5 part of thickener, 0.1 part of pigment, 20 parts of filler, 1 part dispersant, 1.1 parts of defoamer, 1.2 parts of propylene glycol and 0.7 parts of preservative. Among them, the main material is water-based polyurethane resin, the elastic elongation rate is 1200%, and the glass transition temperature is -20°C; the acrylic polymer hollow sphere is a copolymer hollow sphere of methyl methacrylate and butyl acrylate, and the particle size is 40 Micron, the thickener is hydroxyethyl cellulose; the preservative is benzisothienone; the defoamer is silicone; the filler is calcium carbonate; the pigment is indoline.

[0064] Disperse and mix water, dispersant, propylene glycol, pigment and filler in a disperser at 1500 rpm, add d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com