Glass fiber vacuum insulating plate with holes and manufacturing method thereof

A technology of vacuum insulation board and glass fiber board, which is applied in the direction of heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., to achieve the effect of prolonging the service life and expanding the scope of use

Inactive Publication Date: 2011-06-15

SUZHOU V I P NEW MATERIAL

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, vacuum insulation panels are mainly used in refrigeration equipment such as refrigerators and freezers. In view of the structural shape of such thermal insulation equipment itself, vacuum insulation panels are processed into rectangles or squares to facilitate pasting on refrigerators, freezers, cold storage, passenger compartments or mobile homes. On the lining wall, however, when the wall needs to be opened to install pipes or other equipment, the traditional flat vacuum insulation panel cannot meet the requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

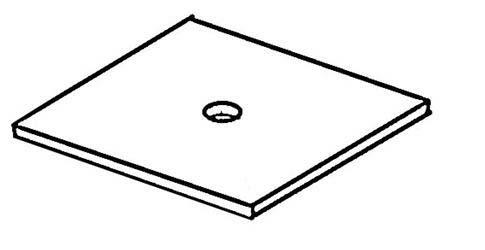

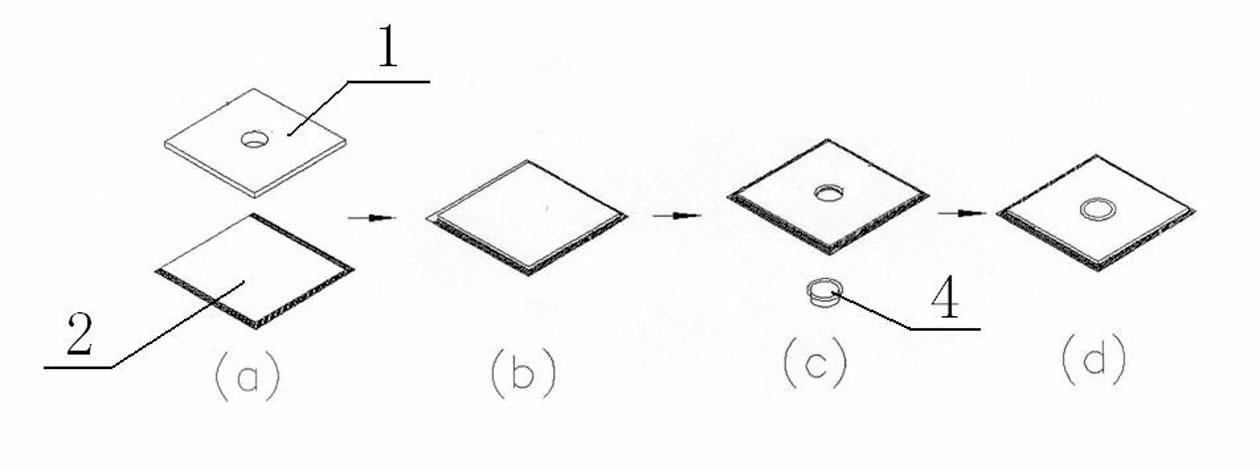

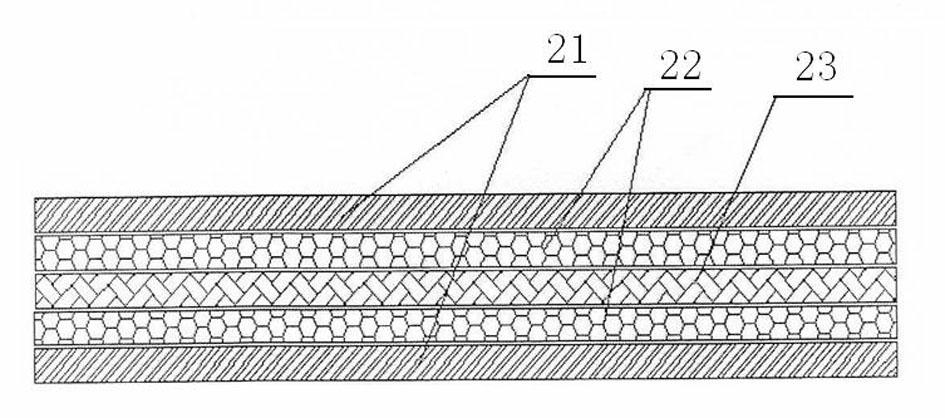

The invention discloses a glass fiber vacuum insulating plate with holes. The vacuum insulating plate disclosed by the invention comprises a core material with holes and moisture barriers, wherein the moisture barriers are covered on the upper and lower surfaces of the core material; the circumference and perforation position of the core material are provided with sealing sides formed by the moisture barriers; and a clamp slot for protecting the sealing sides is sheathed outside the sealing sides in the perforation position of the core material. The vacuum insulating plate disclosed by the invention can be used in places with holes where pipelines or other devices need to be installed, and wires or pipelines pass through the holes reserved on the vacuum insulating plate, thereby expanding the service range of the vacuum insulating plate, and solving the problem that a wall surface can not be made from high thermal insulating materials because of the holes.

Description

A perforated glass fiber vacuum insulation panel and its manufacturing method technical field The invention relates to a thermal insulation material and thermal insulation material engineering technology, in particular to a perforated glass fiber vacuum thermal insulation panel and a manufacturing method thereof. Background technique The thermal conductivity of vacuum insulation panels is as low as 4mW / (m·K), which is currently the best thermal insulation material. At present, vacuum insulation panels are mainly used in refrigeration equipment such as refrigerators and freezers. In view of the structural shape of such thermal insulation equipment itself, vacuum insulation panels are processed into rectangles or squares to facilitate pasting on refrigerators, freezers, cold storage, passenger compartments or mobile homes. On the lining wall, however, when the wall needs to be opened to install pipes or other equipment, the traditional flat vacuum insulation panel cannot mee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L59/065F16L5/00

Inventor 周介明

Owner SUZHOU V I P NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com