General exhaust aftertreatment heat shield

A technology of exhaust gas post-treatment and heat shield, which is applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of high manufacturing cost, high mold opening cost, and many production processes, so as to reduce costs and reduce after-treatment Mold cost, the effect of low mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

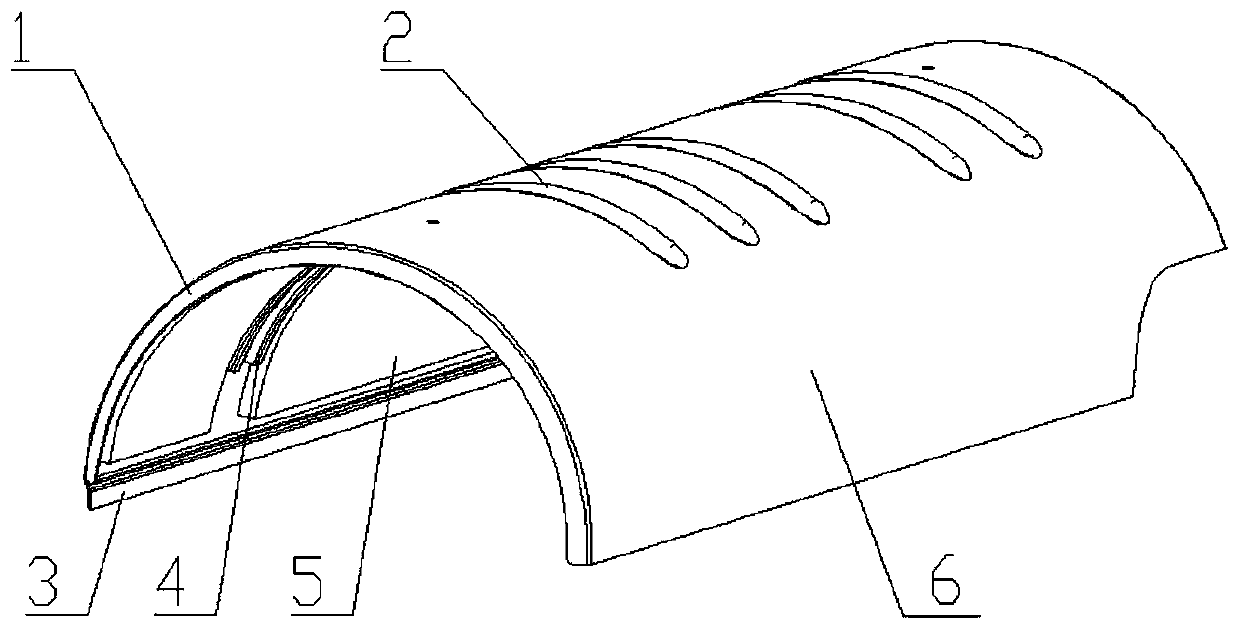

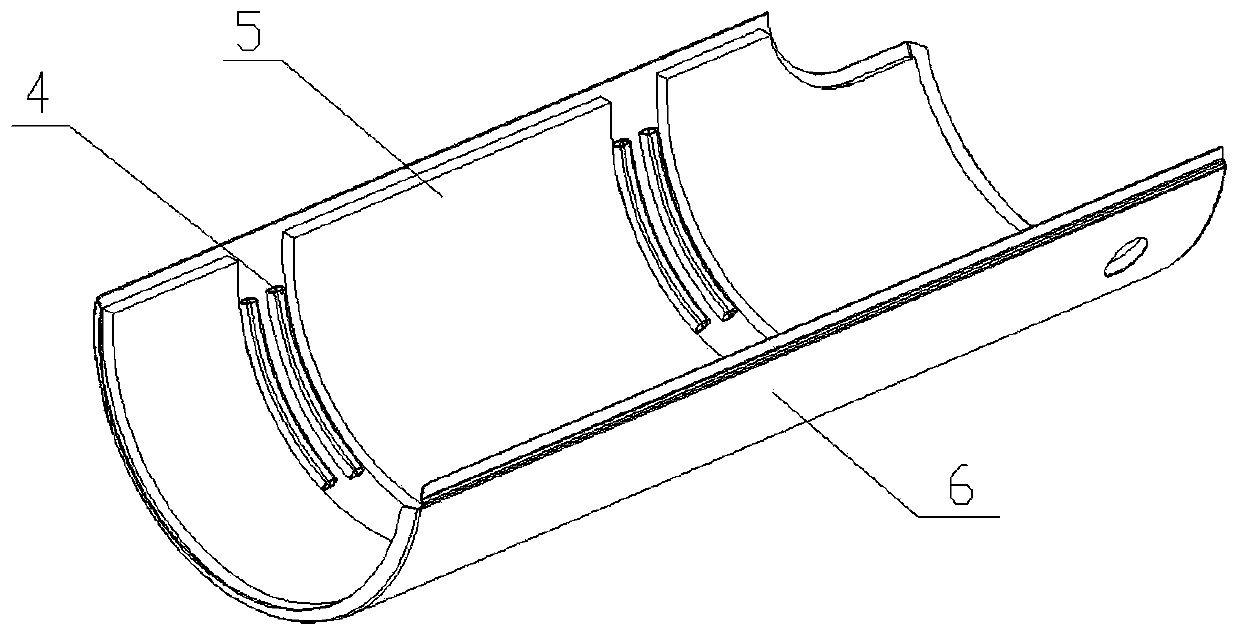

[0016] As shown in the figure: the general-purpose exhaust gas post-treatment heat shield includes the heat shield 6. The cross section of the heat shield 6 is semicircular and can be formed by rounding the mold without stamping, so that the variable length products can share the mold ; One side of the heat insulation sheet 6 is provided with a lap 3, and the lap 3 is an inner buckle-type lap, and two heat-insulation sheets 6 are buckled by the lap 3 to form a cylindrical heat shield, and the inner buckle lap is used Stamping and forming of general-purpose molds, the length of the side-lapping molds is set and covered downwards, so as to adapt to different lengths and achieve universal use. One end of the heat shield 6 is provided with an inclination angle 1, and the end inclination angle is realized by rolling with a general-purpose mold, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com