Novel tempered glass

A kind of tempered glass, a new type of technology, applied in the direction of layered products, etc., can solve the problems of easy condensation on the surface of the glass, blurred vision of the glass, and affecting the field of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

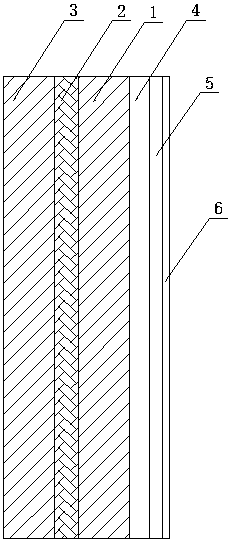

[0014] figure 1 Shown is the novel tempered glass provided by the present invention, comprising a first tempered glass layer 3 and a second tempered glass layer 1; an expanded perlite layer 2 is arranged between the first tempered glass layer 3 and the second tempered glass layer 1 The side of the second toughened glass layer 1 away from the first toughened glass layer 3 is provided with a conductive vacuum coating layer 4; the side of the conductive vacuum coating layer 4 is provided with a silicone colloid layer 5, and the silicone The side of the glue layer 5 is provided with a self-healing layer 6 .

[0015] The self-repairing layer 6 is pre-embedded some capsules containing repairing agent monomers. When the crack penetrates these capsules, the silicone gel layer 5 contains an initiator, which triggers the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com