Plastic film raw material mixing device

A technology of plastic film and mixing device, applied in springs/shock absorbers, cleaning methods and appliances, vibration suppression adjustment, etc., can solve the problems of too simple mixing structure, poor mixing effect of raw materials, affecting product quality, etc. Avoid waste of resources, prevent clogging, and enhance the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

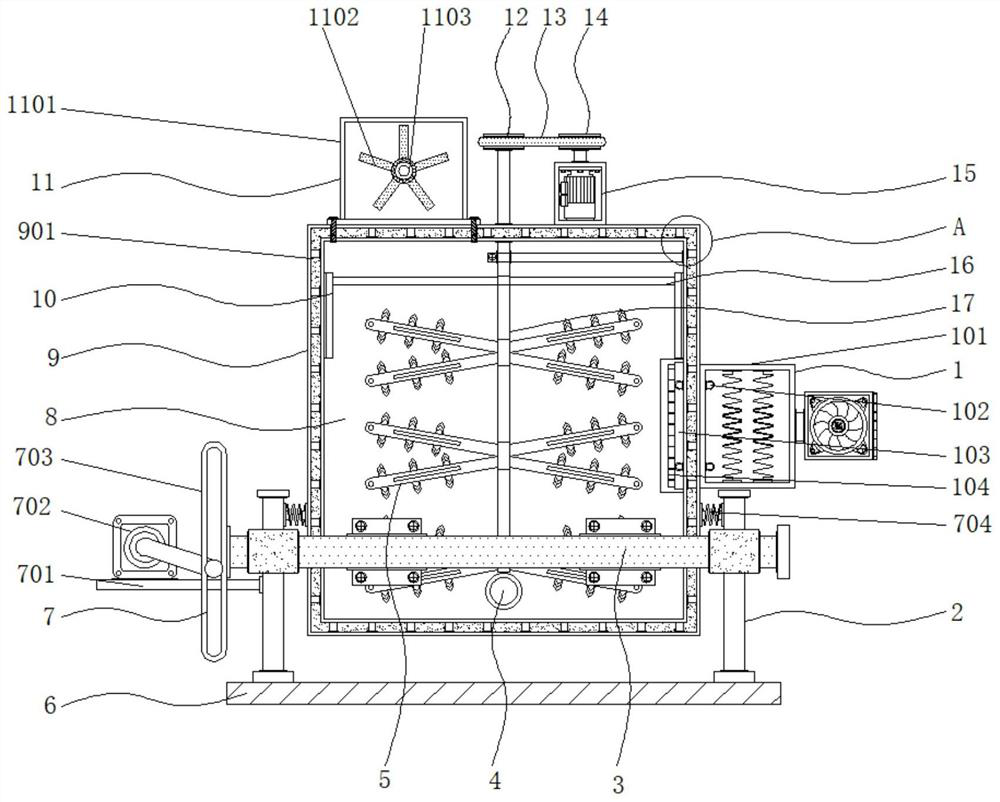

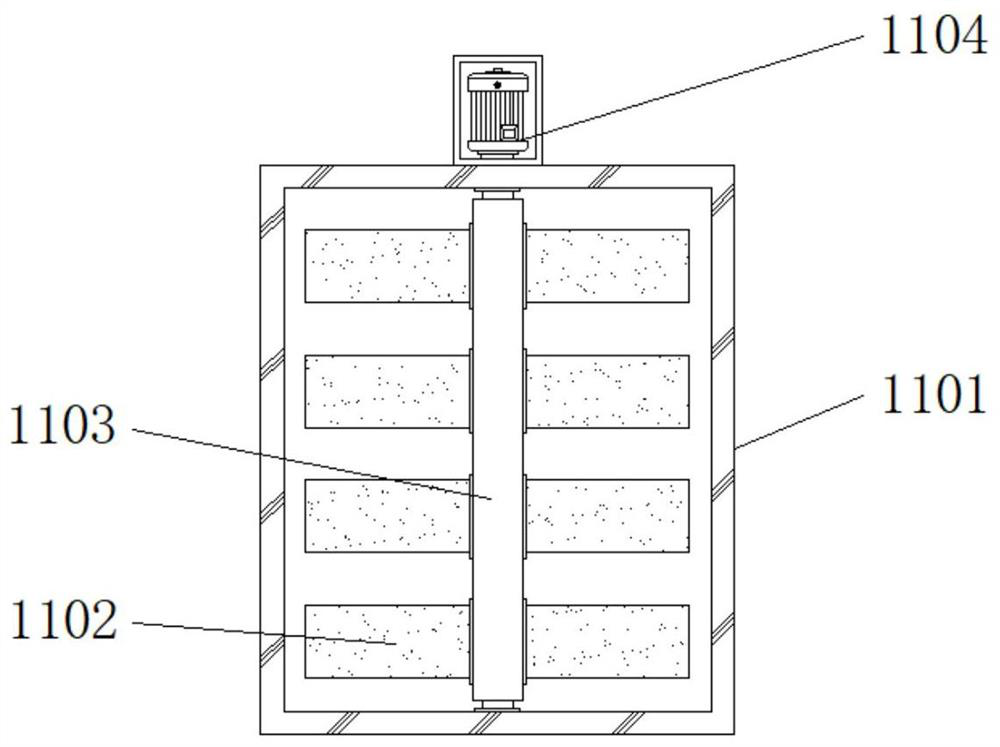

[0035]Example 1: See Figure 1-6 , a plastic film raw material mixing device, comprising a device main body 8, the two ends of the bottom of the device main body 8 are fixedly connected with a fixed support 3, the two sides of the fixed support 3 are fixedly connected with a support plate 2 through a connecting sleeve, and the bottom of the support plate 2 The end is fixedly connected with a bottom plate 6, one side of the fixed support 3 is provided with a vibrating mixing mechanism 7, one side of the top of the device main body 8 is provided with a leveling mechanism 11, one side of the device main body 8 is provided with a heating mechanism 1, and one end of the device main body 8 The bottom end is fixedly connected with a discharge port 4, the inner wall of the device main body 8 is provided with a thermal insulation structure 9, and the inside of the device main body 8 is provided with a uniform mixing mechanism;

[0036] see Figure 1-6 , a plastic film raw material mix...

Embodiment 2

[0038] Embodiment 2: The heating mechanism 1 is composed of a connecting seat 101, a through pipe 102, a distribution pipe 103, a heat pipe 104, a fan 105 and a heating wire 106. The connecting seat 101 is fixedly connected to one side of the device main body 8, and the inside of the connecting seat 101 A heating wire 106 is fixedly connected, the type of the heating wire 106 can be 0Cr25Al5, the other side of the connecting seat 101 is fixedly connected with a fan 105 through a connecting pipe, the type of the fan 105 can be SF, and one side of the connecting seat 101 is fixed Connected with a through pipe 102, the through pipe 102 is provided with two groups and distributed symmetrically with respect to the horizontal center line of the connecting seat 101, and the other side of the through pipe 102 runs through the inside of the device main body 8 and communicates with the inside of the distribution pipe 103. The piping 103 is fixedly connected to one side inside the device ...

Embodiment 3

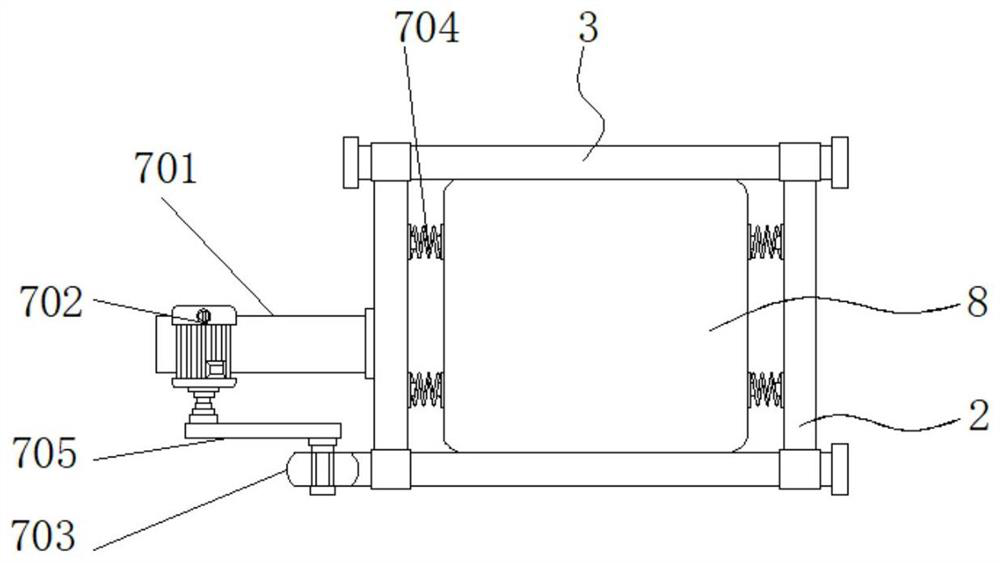

[0040] Embodiment 3: The vibration mixing mechanism 7 is made up of a support base 701, a first servo motor 702, a hollow block 703, a buffer spring 704 and a movable rod 705. The support base 701 is fixedly connected to one side of the support plate 2, and the support base 701 The top end is fixedly connected with the first servo motor 702, the model of the first servo motor 702 can be ASD-A2, the output end of the first servo motor 702 is fixedly connected with the movable rod 705 through the shaft connector, and one end of the movable rod 705 is connected flexibly Inside the hollow block 703, one side of the hollow block 703 is fixedly connected to the fixed bracket 3, and the buffer spring 704 is fixedly connected between the support plate 2 and the device main body 8;

[0041] The elastic coefficients of the buffer springs 704 are equal, and an eccentric structure is formed between the hollow sleeve block 703 and the movable rod 705;

[0042] Specifically, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com