Sintered horizontal hole building block forming mould

A technology of horizontal holes and forming dies, which is applied in the field of forming equipment and building materials machinery manufacturing, can solve the problems of lack of brick extrusion dies, etc., and achieve the effect of promoting healthy development and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

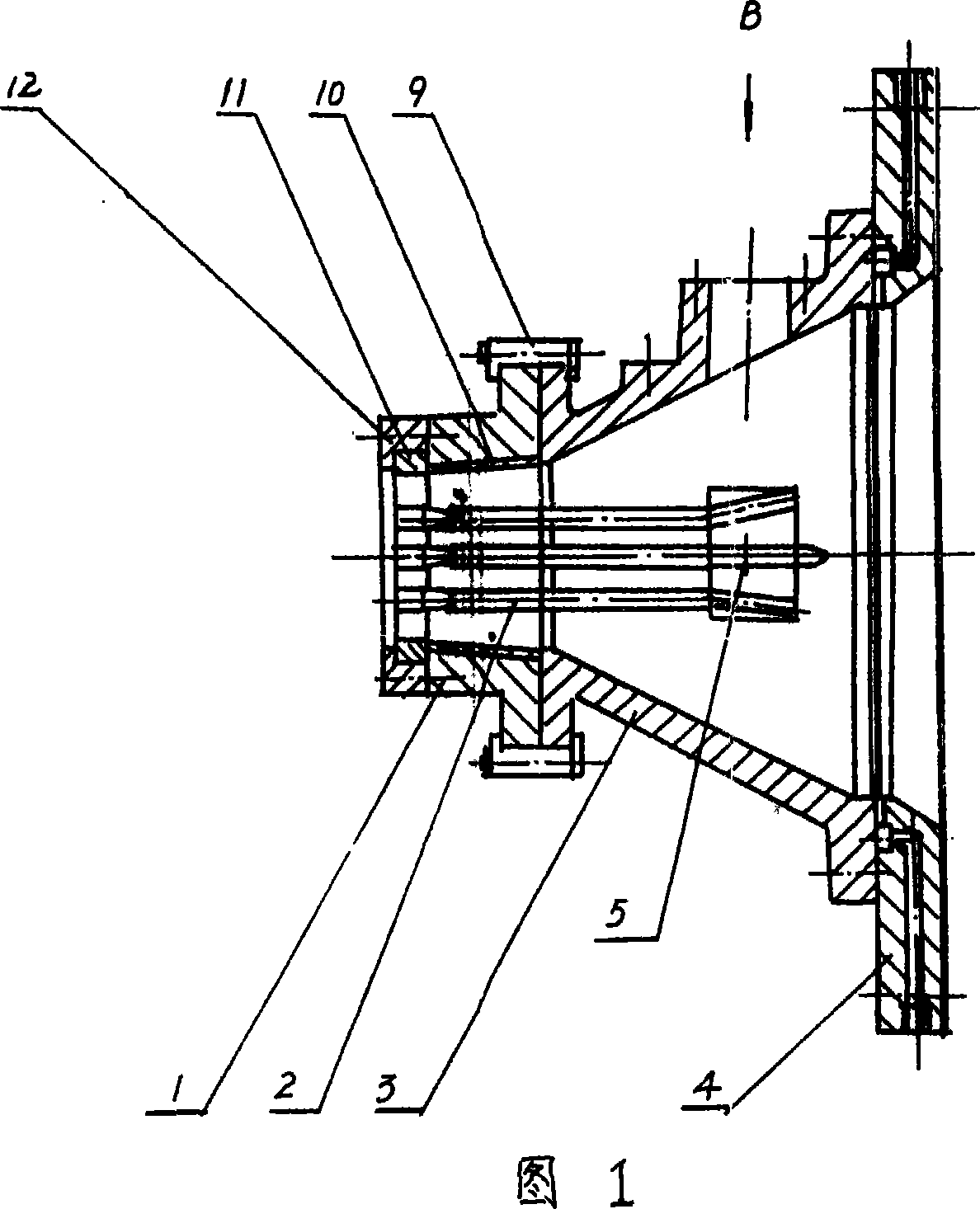

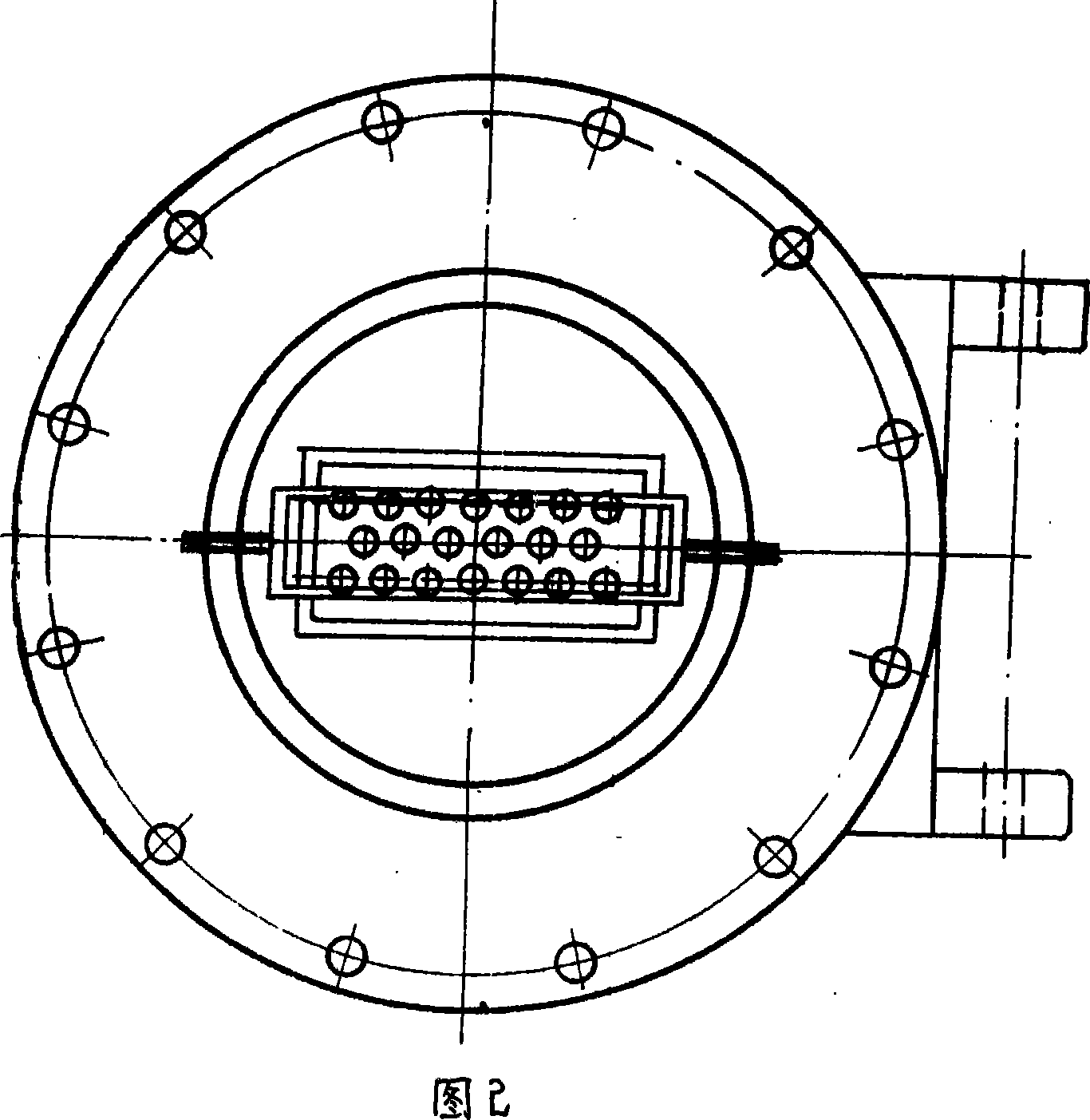

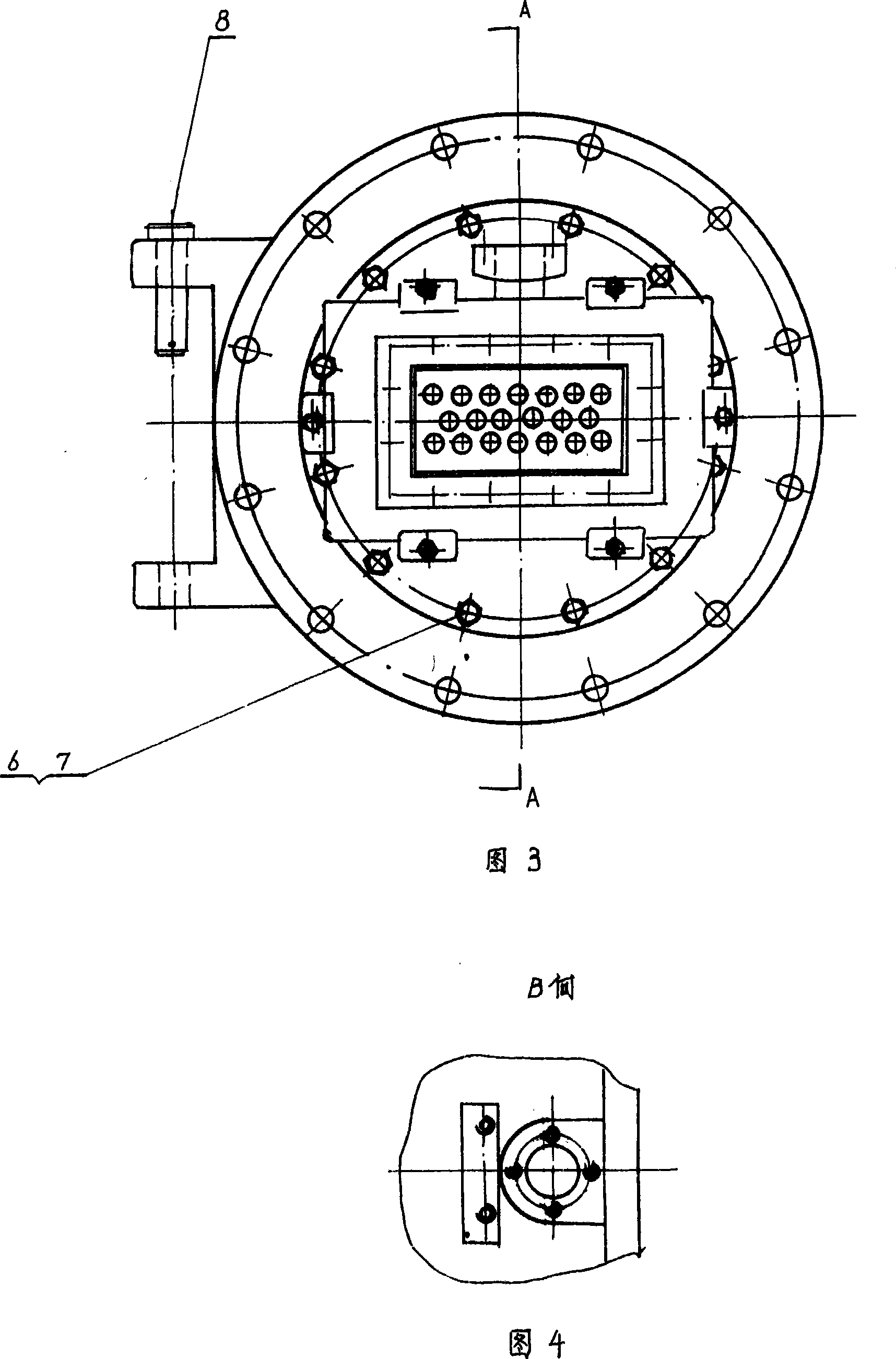

[0031] Accompanying drawing 1-10 has provided the specific embodiment of the present invention.

[0032] 1. Design principles: Based on the existing hard plastic vacuum extruder with specifications above φ50 (extrusion reamer diameter 500mm, extrusion pressure 4mPa, vacuum degree 90%, raw material moisture content 16-19% and other basic data ); the characteristics of non-clay materials such as coal gangue, fly ash, shale, and slag (physical properties such as plasticity, particle size, shrinkage, loss on ignition, etc.) According to the basis, learn from and absorb the advanced technology of mold manufacturing at home and abroad, and create a new type of sintered block forming mold suitable for my country's national conditions.

[0033] 2, technical scheme, compare with existing brick extrusion die, the change on the technical scheme of the present invention mainly comprises:

[0034] 2.1 Change the geometric shape of the machine mouth and the inner cavity of the machine head t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com