Flame-retardant low-dielectric-constant bonding sheet and preparation method thereof

A low dielectric constant, bonding sheet technology, used in film/sheet adhesives, adhesives, flat products, etc., can solve problems affecting the consistency and stability of high-frequency circuit signal transmission, bonding sheet Performance differences, unfavorable large-scale use, etc., to meet the needs of high-frequency signals and stability, simple preparation process, and high combination stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

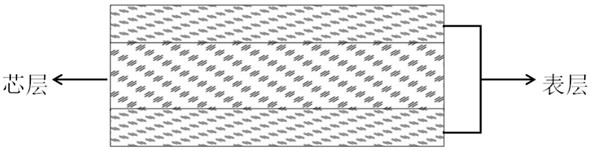

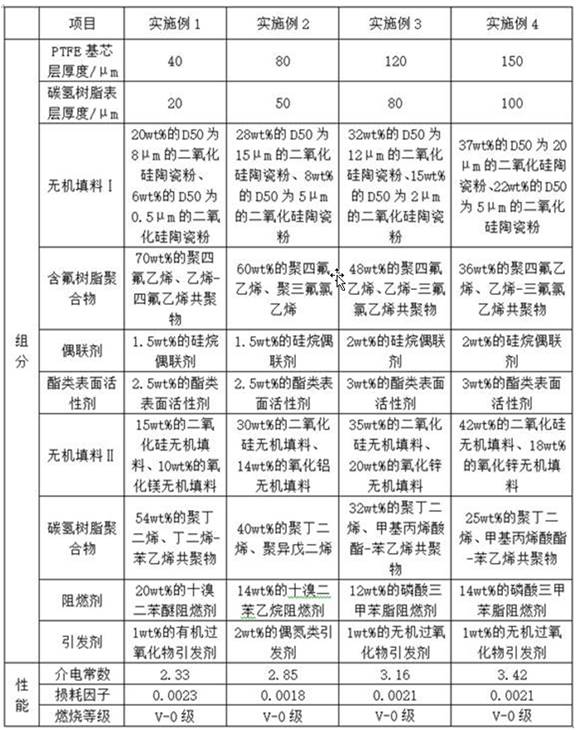

[0046] A flame-retardant low-dielectric constant adhesive sheet, the adhesive sheet includes a middle PTFE-based core layer and hydrocarbon resin surface layers on the upper and lower sides. Among them, the thickness of the PTFE-based core layer in the middle is 40 μm; the thickness of the hydrocarbon resin surface layers on the upper and lower sides are both 20 μm.

[0047] The mass fraction ratio of the raw materials of the PTFE-based core layer of the bonding sheet is 20wt% of silica ceramic powder with a D50 of 8 μm, 6wt% of silica ceramic powder with a D50 of 0.5 μm, and 70wt% of polytetrafluoroethylene , Ethylene-tetrafluoroethylene copolymer, 1.5wt% silane coupling agent, 2.5wt% ester surfactant.

[0048] The mass fraction ratio of the raw materials of the upper and lower hydrocarbon resin surface layers of the bonding sheet is: 15wt% silica inorganic filler, 10wt% magnesium oxide inorganic filler, 54wt% polybutadiene, butadiene-styrene copolymer , 20wt% decabromodiphe...

Embodiment approach 2

[0060] A flame-retardant low-dielectric-constant bonding sheet, the bonding sheet includes a PTFE-based core layer in the middle and hydrocarbon resin surface layers on both upper and lower surfaces. Among them, the thickness of the PTFE-based core layer in the middle is 70 μm; the thickness of the hydrocarbon resin surface layers on the upper and lower sides are both 50 μm.

[0061] The mass fraction ratio of the raw materials of the PTFE-based core layer of the bonding sheet is 28wt% of silica ceramic powder with D50 of 15 μm, 8wt% of silica ceramic powder with D50 of 5 μm, 60wt% of polytetrafluoroethylene, poly Chlorotrifluoroethylene, 1.5wt% silane coupling agent, 2.5wt% ester surfactant.

[0062] The mass fraction ratio of the raw materials of the upper and lower hydrocarbon resin surface layers of the bonding sheet is 30wt% silica inorganic filler, 14wt% alumina inorganic filler, 40wt% polybutadiene, polyisoprene, 14wt% Decabromodiphenylethane flame retardant, 2wt% azo ...

Embodiment approach 3

[0073] A flame-retardant low-dielectric-constant bonding sheet, the bonding sheet includes a PTFE-based core layer in the middle and hydrocarbon resin surface layers on both upper and lower surfaces. Among them, the thickness of the PTFE-based core layer in the middle is 120 μm; the thickness of the hydrocarbon resin surface layers on the upper and lower sides are both 80 μm.

[0074] The mass fraction ratio of the raw materials of the PTFE-based core layer of the bonding sheet is 32wt% of silica ceramic powder with a D50 of 12 μm, 15wt% of silica ceramic powder with a D50 of 2 μm, 48wt% of polytetrafluoroethylene, ethylene -Chlorotrifluoroethylene copolymer, 2wt% silane coupling agent, 3wt% ester surfactant.

[0075] The mass fraction ratio of the raw materials of the upper and lower hydrocarbon resin surface layers of the adhesive sheet is 35wt% silica inorganic filler, 20wt% zinc oxide inorganic filler, 32wt% polybutadiene, methacrylate-styrene copolymer , 12wt% tricresyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com