Stain-resistant high-temperature liquid asphalt coating and preparation method thereof

A technology of liquid asphalt and high temperature resistance, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of poor anti-fouling effect and no anti-fouling effect of polyphenylene sulfide at high temperature , to achieve the effect of improving anti-fouling performance and good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of anti-high temperature liquid asphalt stain coating:

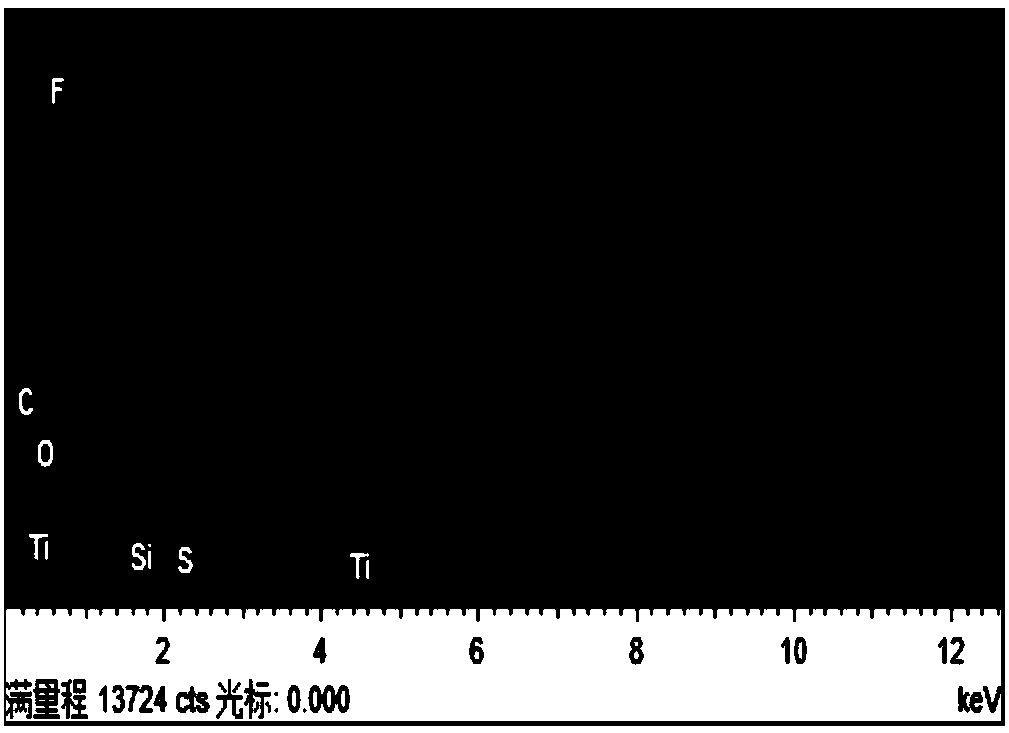

[0036] Step 1: Prepare 100 g of water, 50 g of ethanol, 30 g of polyphenylene sulfide, 18 g of titanium dioxide (50 μm in particle size), and 0.36 g of sodium lauryl sulfate to prepare high-temperature liquid asphalt stain-resistant slurry; 9000 rpm high-speed shear Disperse for 2h;

[0037] Step 2: Mix the anti-high temperature liquid asphalt stain slurry with the hydrophobic modifier, and stir evenly at a stirring speed of 5000 rpm for 30 minutes to form an anti-high temperature liquid asphalt stain coating. In the hydrophobic modifier, 1 g of aluminum oxide nanopowder with a particle size of 500 nm, 1 g of ethoxylated alkylphenol ammonium sulfate, and 20 g of polyperfluoroethylene propylene emulsion with a solid content of 40% of the emulsion.

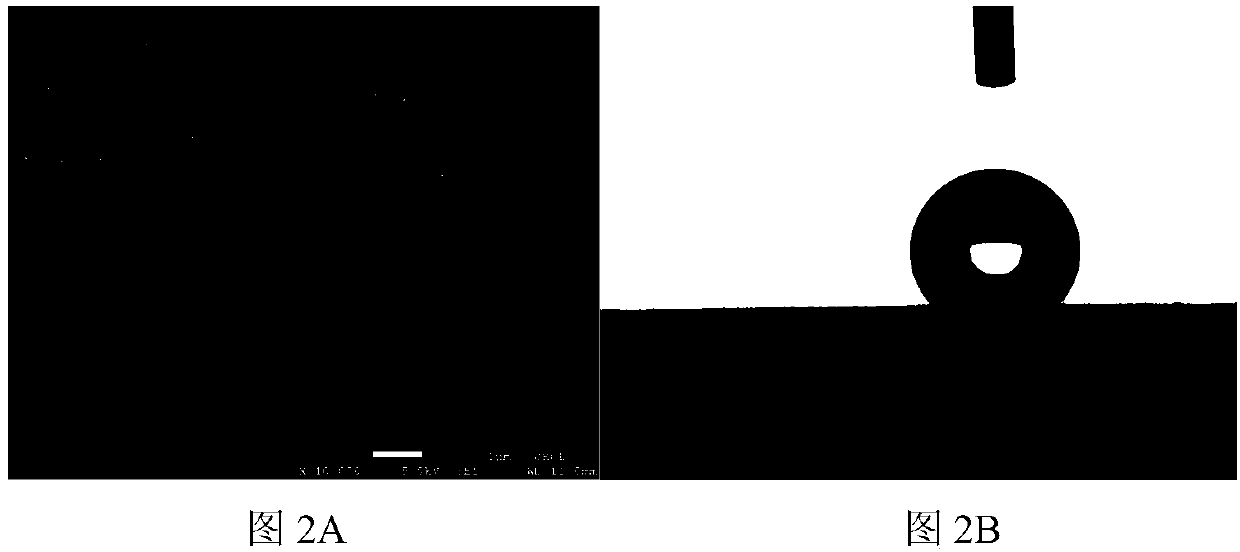

[0038] 2. Preparation of anti-high temperature liquid asphalt stain coating:

[0039] Clean and degrease the surface of the stainless steel substrate; ...

Embodiment 2

[0045] A kind of preparation of anti-high temperature liquid asphalt stain coating, concrete steps are as follows:

[0046] 1. Preparation of anti-fouling coating:

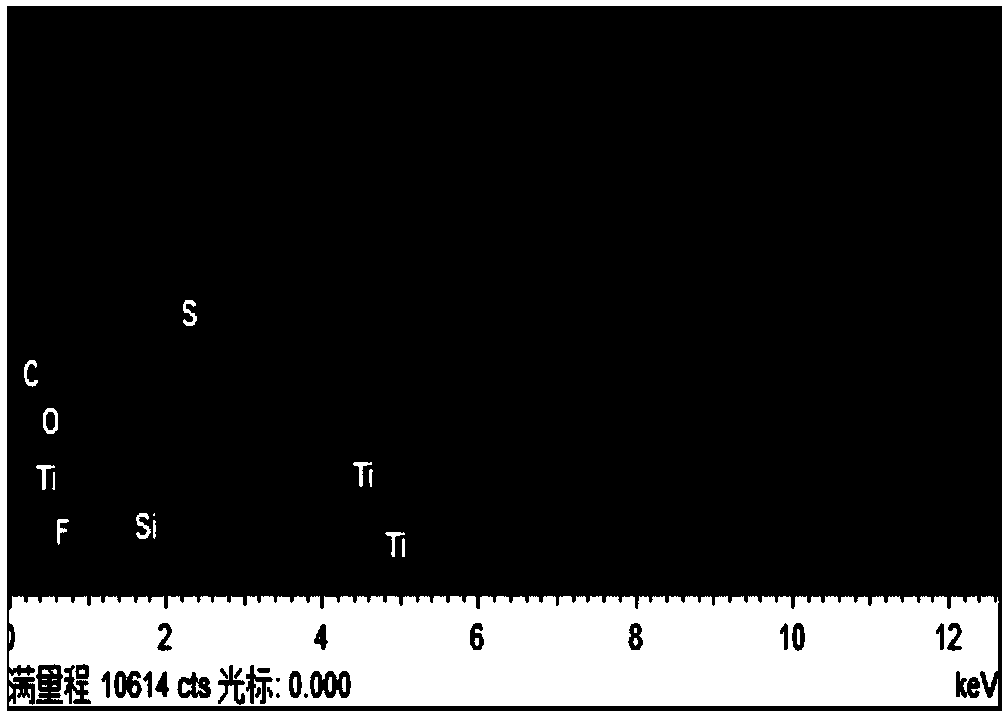

[0047] Step 1: Prepare 100g of water, 100g of propanol, 60g of polyphenylene sulfide, 6g of aluminum oxide (particle size 500nm), and 1.2g of sodium dodecylsulfonate to make anti-high temperature liquid asphalt contamination slurry; 6000 rpm / min high speed shear dispersion 4h;

[0048] Step 2: 20g of titanium dioxide with a particle size of 50nm, 50g of polyoxyethylene octylphenol ether-10 and 200g of polytetrafluoroethylene emulsion with a solid content of 20% are configured as a hydrophobic modifier; 100g of anti-high temperature liquid asphalt is stained Stir the slurry and 100g of hydrophobic modifier evenly to form an anti-high temperature liquid asphalt stain coating, the stirring speed is 5000 rpm, and the stirring time is 20min.

[0049] 2. Preparation of anti-high temperature liquid asphalt stain coat...

Embodiment 3

[0053] A kind of preparation of anti-high temperature liquid asphalt stain coating, concrete steps are as follows:

[0054] 1. Preparation of anti-fouling coating:

[0055] Step 1: Prepare 100 g of water, 20 g of ethylene glycol, 12 g of polyphenylene sulfide, 7.2 g of silicon dioxide (500 μm in particle size), and 0.24 g of sodium dodecylbenzene sulfonate to prepare a slurry for preventing high-temperature liquid asphalt contamination; 8000 rpm high-speed shear dispersion for 3 hours;

[0056] Step 2: Prepare 5g of silicon dioxide with a particle size of 500nm, 5g of polyoxyethylene octylphenol ether-10, and 100g of fluorine-containing acrylic emulsion with a solid content of 30% to form a hydrophobic modifier; dip 100g of high-temperature resistant liquid asphalt Stir the dirty slurry and 50g of hydrophobic modifier evenly to form an anti-high temperature liquid asphalt stain coating, the stirring speed is 3000 rpm, and the stirring time is 20min.

[0057] 2. Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com