Superhard composite coated cutting tool and preparation method thereof

A composite coating and superhard technology, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problem that the bonding force between cubic boron nitride coating and cemented carbide substrate is not strong, which affects the coating cutting Problems such as tool quality and service life, thermal expansion coefficient mismatch, etc., achieve the effect of alleviating sudden changes in interface physical properties, strong interlayer bonding, and avoiding shedding and fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

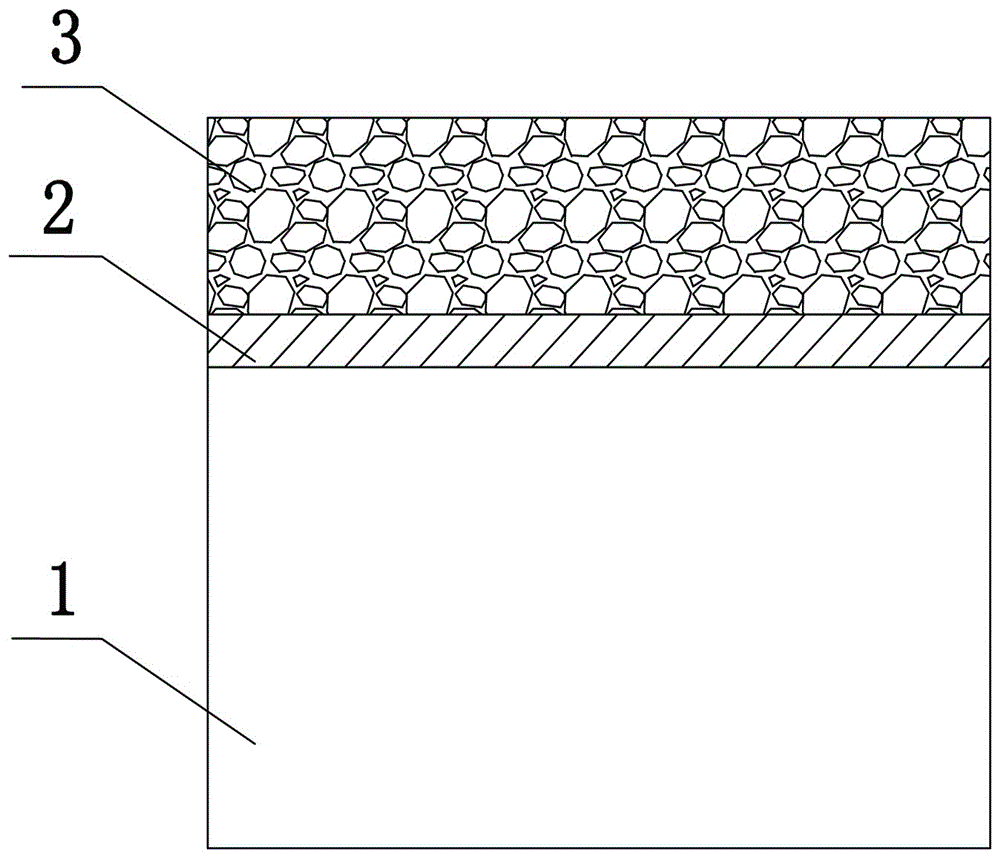

[0022] This embodiment provides a superhard composite coating cutter, its structure is as follows figure 1 As shown, it includes a cemented carbide substrate 1 for carrying the superhard composite coating, and a metal transition layer 2 sprayed on the surface of the cemented carbide 1 and a cubic boron nitride coating doped with metallic nickel in sequence. Layer 3.

[0023] Wherein, in the cubic boron nitride coating doped with metal nickel, the metal nickel is coated on the surface of the cubic boron nitride crystal, and the total mass of the metal nickel accounts for the total mass of the surface coated with metal nickel 20% of the total mass of the cubic boron nitride crystal. In this embodiment, the metal transition layer 2 is a metal titanium layer, the thickness of the metal titanium layer is 50 microns, and the thickness of the cubic boron nitride coating doped with metal nickel is 400 microns.

[0024] The present embodiment also provides a method for preparing the ...

Embodiment 2

[0028] This embodiment provides a superhard composite coated tool, the specific structure of which is the same as that of the superhard composite coated tool in Example 1.

[0029] This embodiment also provides a method for preparing the above-mentioned superhard composite coating tool, and the specific steps are roughly the same as those in Embodiment 1, except that:

[0030] In the step (1) of this embodiment, the metal transition layer coated on the surface of the cemented carbide substrate is a metal chromium layer with a thickness of 45 microns;

[0031] The process parameters of the supersonic flame spraying method in the step (1) of this embodiment are: the fuel pressure is 1.0 MPa, the fuel flow rate is 10 L / h, the oxygen pressure is 0.5 MPa, the oxygen flow rate is 10 L / h, the powder feeding The flow rate is 5 kg / h, the powder feeding gas is nitrogen, and the spraying distance is 200 mm.

Embodiment 3

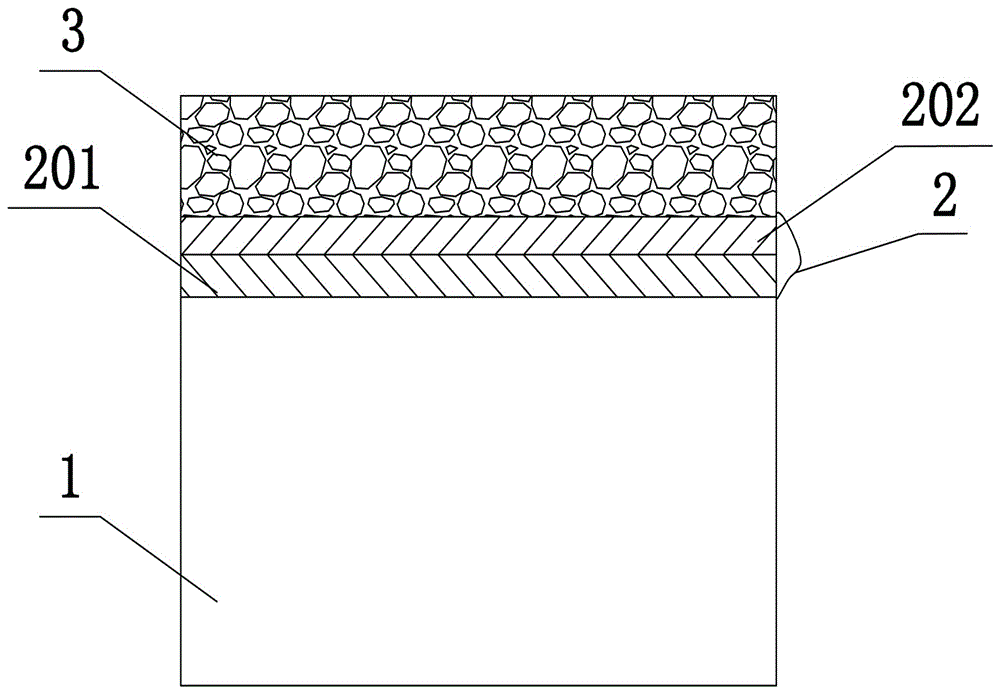

[0033] This embodiment provides a superhard composite coating tool, the specific structure is as follows figure 2 As shown, it includes a cemented carbide substrate 1 for carrying the superhard composite coating, and a metal Cr layer 201, a metal Nb layer 202, and a metal nickel doped layer that are sequentially coated on the surface of the cemented carbide 1. Cubic boron nitride coating3.

[0034] Wherein, in the boron nitride coating doped with metallic nickel, the metallic nickel is coated on the surface of the boron nitride crystal, and the total mass of the metallic nickel accounts for all of the surface coated with metallic nickel. 50% of the total mass of the cubic boron nitride crystal. Both the metal Cr layer 201 and the metal Nb layer 202 have a thickness of 25 microns, and the thickness of the cubic boron nitride coating 3 doped with metal nickel is 300 microns.

[0035] This embodiment provides a method for preparing a superhard composite coating tool, the speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com