Preparation method of high-performance textured copper-nickel alloy composite base band for coated conductor

A copper-nickel alloy and composite base strip technology is applied in the field of textured metal base strips for strengthening high-temperature coating superconductors. The effect of strong interlayer bonding and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

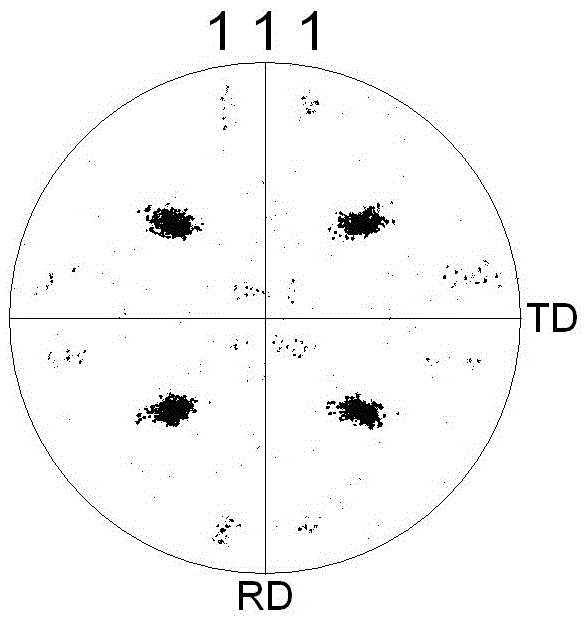

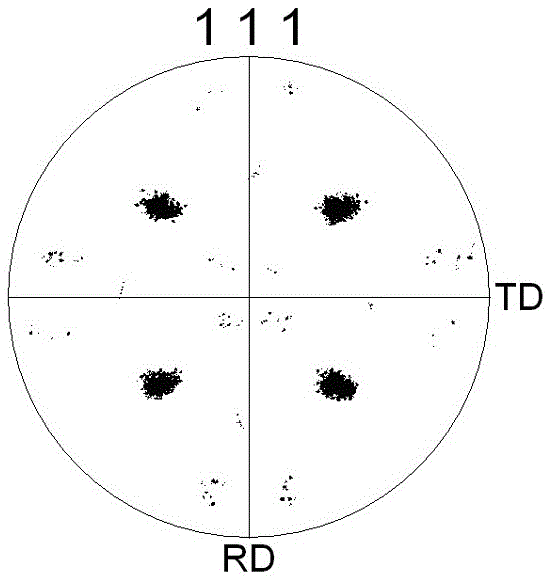

Image

Examples

Embodiment 1

[0020] Step S100: Preparation of copper-nickel alloy composite ingot

[0021] Step S101: Using high-energy ball milling to obtain copper-nickel mixed powder with a nickel content of 60% by weight and a nickel-tungsten mixed powder with a tungsten content of 9 atomic percent, respectively, define the copper-nickel mixed powder and nickel-tungsten mixed powder For powder A and powder B;

[0022] Step S102: Put the powder A and powder B obtained in step S101 into the mold layer by layer in the order of A-B-A, and then use cold isostatic pressing to form a three-layer initial composite blank with the outer layer A and the core layer B, in which the cold The isostatic pressure is 300MPa, and the holding time is 10min;

[0023] Step S103: Sintering the initial composite ingot obtained in step S102 by hot isostatic pressing to obtain a layered copper-nickel alloy composite ingot. The pressure medium is nitrogen;

[0024] Step S200: Cold rolling and recrystallization heat treatment...

Embodiment 2

[0029] Step S100: Preparation of copper-nickel alloy composite ingot

[0030] Step S101: Using high-energy ball milling to obtain copper-nickel mixed powder with a nickel content of 60% by weight and a nickel-tungsten mixed powder with a tungsten content of 10 atomic percent, respectively, define the copper-nickel mixed powder and nickel-tungsten mixed powder respectively For powder A and powder B;

[0031] Step S102: Put the powder A and powder B obtained in step S101 into the mold layer by layer in the order of A-B-A, and then use cold isostatic pressing to form a three-layer initial composite blank with the outer layer A and the core layer B, in which the cold The isostatic pressure is 300MPa, and the holding time is 10min;

[0032] Step S103: hot isostatic pressing and sintering the initial composite billet obtained in step S102 to obtain a layered copper-nickel alloy composite billet. The pressure medium is nitrogen;

[0033] Step S200: Cold rolling and recrystallizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com