Composite flexible magnetic strip and preparation method thereof

A flexible magnetic strip and flexible technology, applied in the manufacture of inductors/transformers/magnets, magnets, magnetic materials, etc., can solve the problems of protective jacket creases, NdFeB magnetic powder corrosion, poor thermal shrinkage temperature control, etc. Can be super strong, long service life, good-looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Case 1.

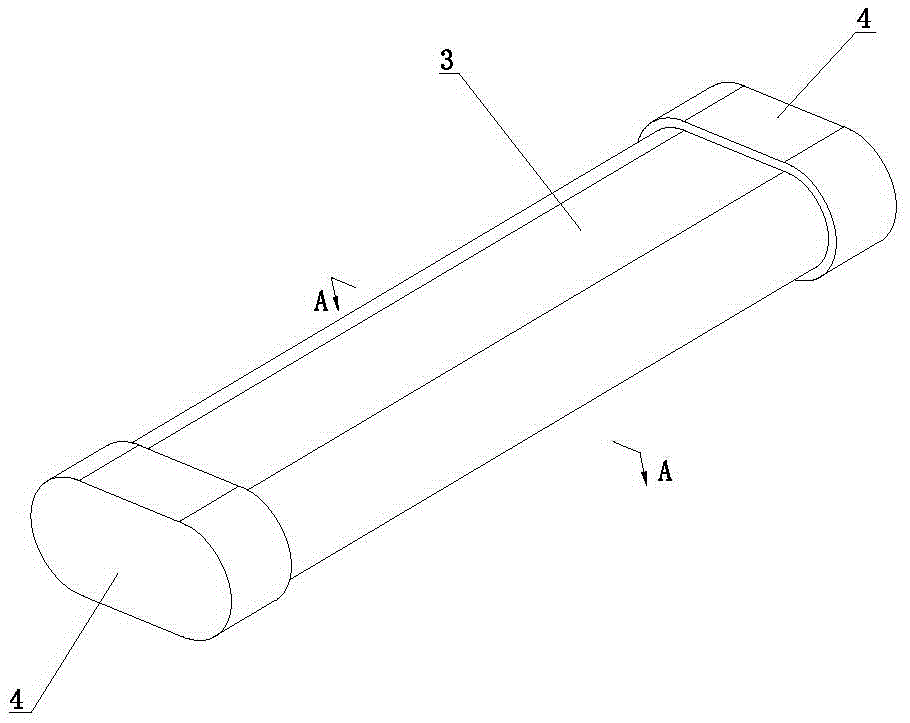

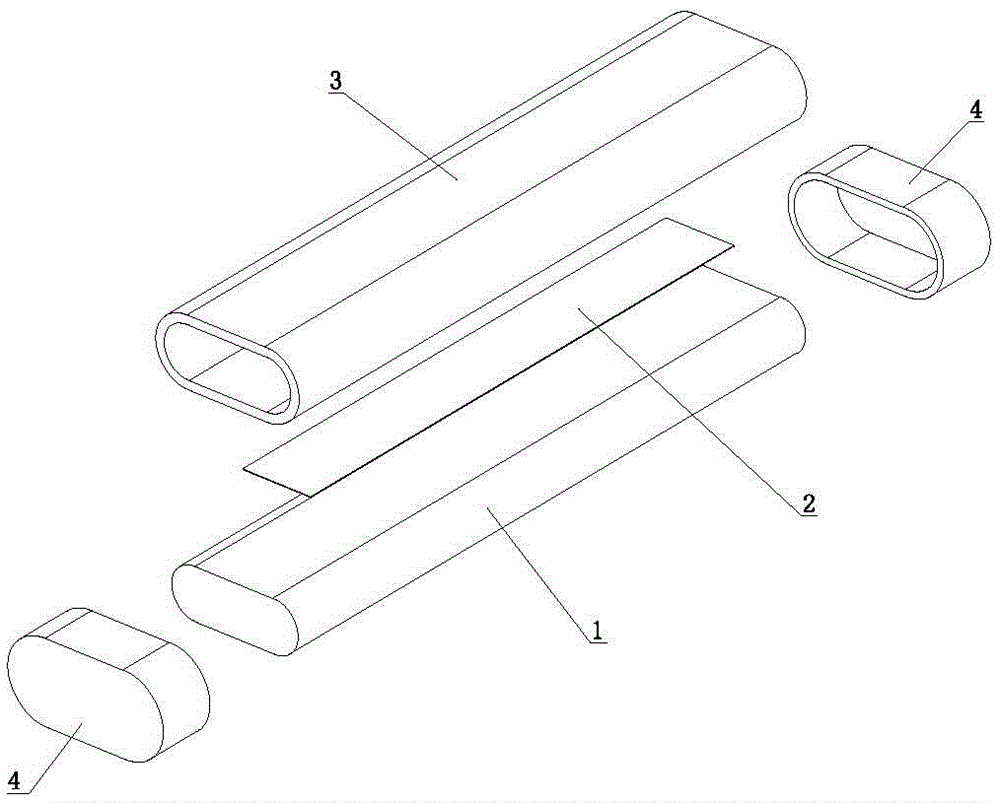

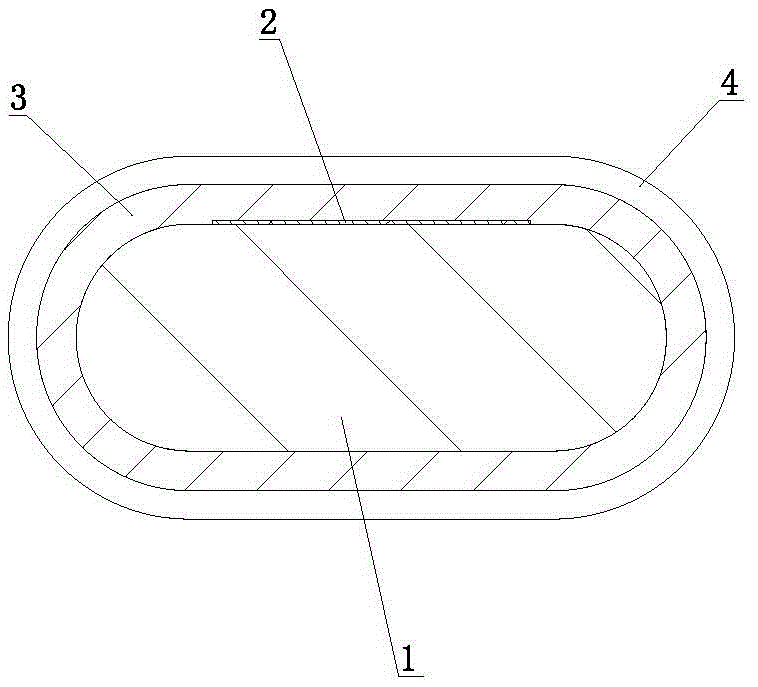

[0022] see Figure 1 to Figure 3 , using NdFeB magnetic powder 90%wt, rubber 9%wt, coupling agent and other additives 1%wt, crushed after mixing to make particles of uniform size. Put the granules into the rubber extruder, extrude them through a die with 13.8*3.5 arcs at both ends, and make a rare earth magnetic strip of the corresponding size, that is, the rubber magnetic body 1, and print the logo on the surface of the rubber magnetic body 1 through the printing wheel After the information is formed, a product information printing coating 2 or a product information display interlayer is formed, and then a 0.2mm thick thermoplastic flexible elastic layer 3 is extruded on the surface of the rubber magnetic body 1, and finally a 14.2mm wide and 3.9mm thick arc at both ends is obtained. The flexible rare earth magnetic strip, the cross-sectional shape see image 3 . Then, after cutting the length according to the specification, injection molding is performed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com