Plastic non-chrome roughening treatment method and water-saving electroplating method thereof

A roughening treatment and plastic technology, which is applied in the field of chrome-free roughening treatment of plastics and water-saving electroplating, can solve the problems of process defects, uneven bonding force, limited plastic substrates, etc., and achieves broad prospects, stable process, excellent The effect of interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

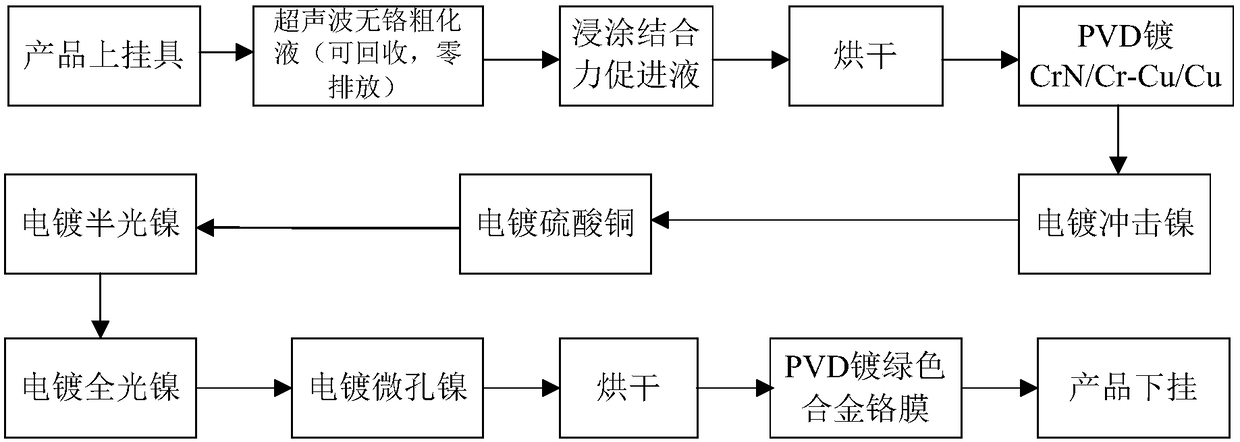

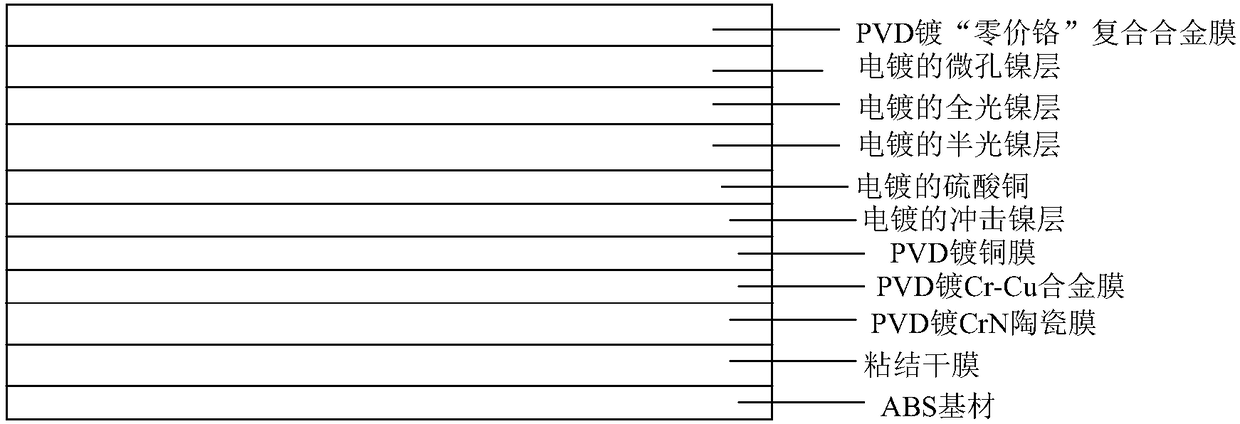

[0081] Take the injection molding workpiece of ABS plastic, follow the above steps and figure 1 Flow chart for chrome-free roughening green electroplating.

[0082] Step 1: Put the ABS workpiece into a chromium-free roughening solution for cleaning (removing oil and wax) and micro-corrosion process. The temperature in the tank is 30°C, and it is cleaned by ultrasonic vibration for 5 minutes.

[0083] Step 2: Take out the ABS workpiece, put it into another modified bonding solution of the adhesion promoter, and dip the adhesion promoter for 40 seconds, then take it out, put it in an oven and bake it at 70°C for 40 minutes.

[0084] Step 3: Implement oxygen plasma activation treatment in the PVD furnace, hang the ABS workpiece in the PVD furnace, and evacuate to 7×10 - 3 Pa, and then implement oxygen plasma glow oxidation on the surface of the workpiece, the treatment time is 5min, the bias voltage is 300V, the flow rate of argon gas is 500SCCM, and the flow rate of oxygen ga...

Embodiment 2

[0103] The injection molded parts of PC / ABS plastics are subjected to chromium-free roughening green electroplating according to the technical scheme of the present invention.

[0104] Step 1: Put the PC / ABS workpiece (the content of ABS is 75%, the content of PC is 25%) into the chromium-free roughening solution for cleaning (removing oil and wax) and micro-corrosion process. The temperature in the tank is 40°C, and the ultrasonic vibration cleaning is performed for 18 minutes.

[0105] Step 2: Take out the PC / ABS workpiece, put it into another modified adhesive solution of the adhesion promoter, and dip the adhesion promoter for 45 seconds, then take it out, put it in an oven and bake it at 70°C for 45 minutes.

[0106] Step 3: Implement oxygen plasma activation treatment in the PVD furnace, hang the PC / ABS workpiece into the PVD furnace, and evacuate to 7×10 -3 Pa, and then implement oxygen plasma glow oxidation on the surface of the workpiece, the treatment time is 5min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com