Environmentally-friendly automotive trim composite material and preparation method thereof

A composite material and automotive interior technology, which is applied in the field of environment-friendly automotive interior composite materials and its preparation, can solve the problems of product surface texture, poor color consistency, difficult color replacement, and limited texture patterns, etc., to achieve beautiful surface, Excellent processing and forming performance, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

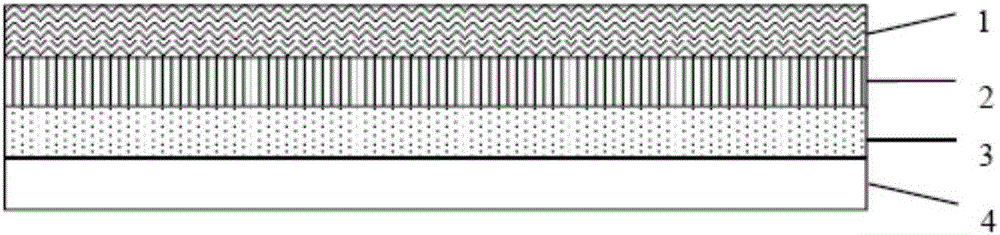

[0107] In this embodiment, an environment-friendly automotive interior composite material is provided, such as figure 1 As shown, it includes a skin layer (1), a foam layer (2), and a skeleton structure (4) bonded to the lower surface of the foam layer through the hot melt adhesive layer (3), and the skin layer is TPO The film layer, the foam layer is a PPF foam layer, the hot melt adhesive layer is a TPU hot melt adhesive layer, and the skeleton structure is an ABS modified PP composite material.

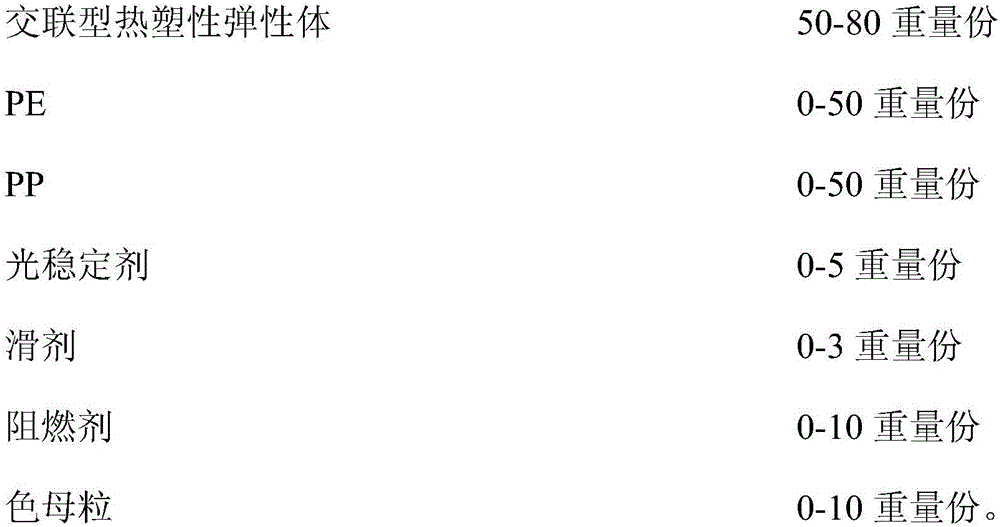

[0108] The raw material of described TPO film layer comprises following composition:

[0109]

[0110]

[0111] The light stabilizer includes 2 parts by weight of an ultraviolet absorber.

[0112] The raw material of described cross-linked thermoplastic elastomer comprises following composition:

[0113]

[0114] The other additives include anti-aging agents, light stabilizers and antioxidants.

[0115] The TPU hot melt adhesive layer is prepared from TPU hot melt adhes...

Embodiment 2

[0131] In this embodiment, an environment-friendly automotive interior composite material is provided, such as figure 1 As shown, it includes a skin layer (1), a foam layer (2), and a skeleton structure (4) bonded to the lower surface of the foam layer through the hot melt adhesive layer (3), and the skin layer is TPO The film layer, the foam layer is a PPF foam layer, the hot melt adhesive layer is a TPU hot melt adhesive layer, and the skeleton structure is an ABS modified PP composite material.

[0132] The raw material of described TPO film layer comprises following composition:

[0133]

[0134] The light stabilizer includes 0.1 part by weight of an ultraviolet absorber.

[0135] The raw material of described cross-linked thermoplastic elastomer comprises following composition:

[0136]

[0137] The other additives include anti-aging agents and antioxidants.

[0138] The raw material of described TPU hot-melt adhesive layer comprises following composition:

[01...

Embodiment 3

[0157] In this embodiment, an environment-friendly automotive interior composite material is provided, such as figure 1 As shown, it includes a skin layer (1), a foam layer (2), and a skeleton structure (4) bonded to the lower surface of the foam layer through the hot melt adhesive layer (3), and the skin layer is TPO The film layer, the foam layer is a PPF foam layer, the hot melt adhesive layer is a TPU hot melt adhesive layer, and the skeleton structure is an ABS modified PP composite material.

[0158] The raw material of described TPO film layer comprises following composition:

[0159]

[0160] The light stabilizer includes 2 parts by weight of an ultraviolet absorber.

[0161] The raw material of described cross-linked thermoplastic elastomer comprises following composition:

[0162]

[0163] The other additives include anti-aging agents, light stabilizers and antioxidants.

[0164] The raw material of described TPU hot-melt adhesive layer comprises following c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com