Layered titanium-aluminum steel composite strip coil material and preparation method thereof

A composite strip and composite rolling technology, which is applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as unstable product quality, large impact on product quality, and inability to continue production, and achieve raw material saving and composite performance. Excellent, strong interlayer bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

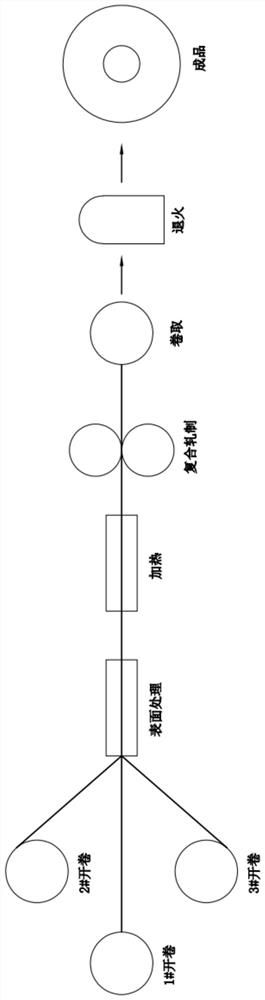

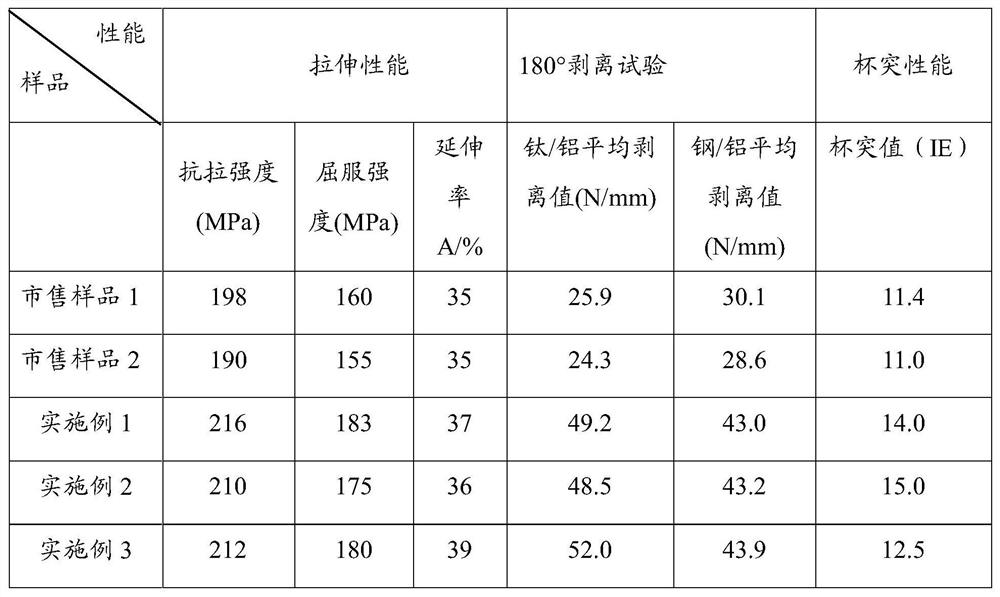

[0033] refer to figure 1 , a kind of preparation method of layered titanium-aluminum-steel composite coil material of the present invention, comprises the following steps:

[0034] Step 1, put the pure titanium coil raw material, aluminum coil raw material and stainless steel coil raw material into the corresponding uncoiling equipment respectively, so that the aluminum coil raw material is in the middle position, and the pure titanium coil raw material and the stainless steel coil raw material are respectively located in the aluminum The upper and lower sides of the coil raw material; the specifications of the raw material are: pure titanium coil raw material: brand TA1, thickness 0.5mm. Stainless steel coil raw material, grade sus430, thickness 0.6mm. Raw material of aluminum coil: grade 1060, thickness 2.3mm.

[0035] Step 2, uncoiling the pure titanium coil raw material, the aluminum coil raw material and the stainless steel coil raw material simultaneously, the uncoilin...

Embodiment 2

[0037] refer to figure 1 , a preparation method of layered titanium-aluminum-steel composite coil material, comprising the following steps:

[0038] Step 1, put the pure titanium coil raw material, aluminum coil raw material and stainless steel coil raw material into the corresponding uncoiling equipment respectively, so that the aluminum coil raw material is in the middle position, and the pure titanium coil raw material and the stainless steel coil raw material are respectively located in the aluminum The upper and lower sides of the coil raw material; the specifications of the raw material are: pure titanium coil raw material: brand TA2, thickness 0.3mm. Stainless steel coil raw material, grade sus310, thickness 0.4mm. Raw material of aluminum coil: grade 3003, thickness 1.8mm.

[0039]Step 2, uncoiling the pure titanium coil raw material, the aluminum coil raw material and the stainless steel coil raw material simultaneously, the uncoiling tension of the aluminum coil ra...

Embodiment 3

[0041] refer to figure 1 , a preparation method of layered titanium-aluminum-steel composite coil material, comprising the following steps:

[0042] Step 1, put the pure titanium coil raw material, aluminum coil raw material and stainless steel coil raw material into the corresponding uncoiling equipment respectively, so that the aluminum coil raw material is in the middle position, and the pure titanium coil raw material and the stainless steel coil raw material are respectively located in the aluminum The upper and lower sides of the coil raw material; the specifications of the raw material are: pure titanium coil raw material: grade TA1, thickness 0.6mm. Stainless steel coil raw material, grade sus430, thickness 0.8mm. Raw material of aluminum coil: grade 1060, thickness 2.6mm.

[0043] Step 2, uncoiling the pure titanium coil raw material, the aluminum coil raw material and the stainless steel coil raw material simultaneously, the uncoiling tension of the aluminum coil r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com