Design method for control transmission lines on same layer and with different impedance

An impedance control and design method technology, applied in the field of electronics, can solve the problems affecting the signal integrity of the 100-ohm transmission line, the difficulty of impedance control, and the difficulty of impedance design, so as to achieve the effect of optimizing integrity, ensuring impedance continuity, and optimizing design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

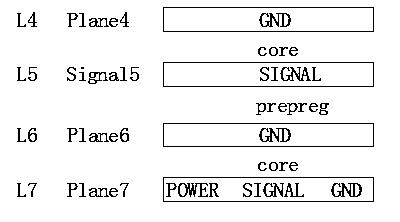

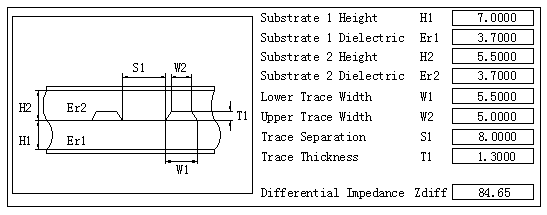

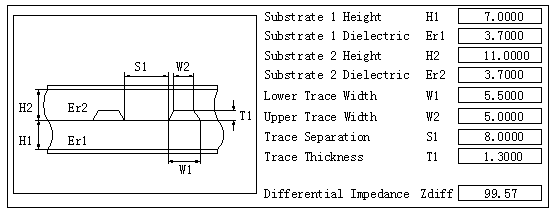

[0013] attached figure 1 It is a schematic diagram of the laminated structure of the computing main board in this embodiment, as shown in the attached figure 1 As shown, in the computing motherboard of the server, Plane4 (L4) is the GND layer, Plane5 (L5) is the SIGNAL layer, Plane6 (L6) is the GND layer, and Plane7 (L7) is the POWER, SIGNAL, and GND layers; among them, 85 ohm , 100 ohm impedance line is located on the Signal5 layer, and the upper and lower reference layers are Plane4 and Plane6 respectively; figure 2 As shown, in this embodiment, the 85 ohm impedance line is designed to have a trace width of 5.5Mil, a trace separation of 8Mil, and a transmission line thickness of 1.3Mil, and the distance H1 between Signal5 and Plane4 is 7 Mil, the distance H2 between Signal5 and Plane6 is 5.5 Mil, this design ensures that the 85 ohm transmission line impedance is controllable, and the line width design is optimal;

[0014] However, this design will result in a narrower lin...

Embodiment 2

[0016] In a blade server, there is an 85-ohm PCIE3.0 bus and a 14Gbps transmission rate 14Gbps impedance-controlled FDR bus in a blade server. Ohm transmission lines, of which there are many 85-ohm buses, and only 16 pairs of differential lines for 100-ohm buses. In this embodiment, the 85 ohm transmission line is designed to have a line width of 6Mil and a line spacing of 8Mil, and the 100 ohm transmission line is designed to have a line width of 6.5Mil and a line spacing of 9Mil; at the same time, in order to ensure the impedance design of 100 ohms, this embodiment uses a 100 ohm transmission line The lower reference plane is hollowed out, so that the 100 ohm transmission line refers to the second layer plane below, the length of H2 (the distance between Plane3 and Plane4) is increased, and the impedance is increased to meet the 100 ohm design without reducing the line width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com