Reciprocating type corrosion fretting wear testing machine

A fretting wear and reciprocating technology, which is applied in weather resistance/light resistance/corrosion resistance, wear resistance testing, measuring devices, etc., can solve the problem of inability to apply high-precision small samples and small loads, hydraulic systems prone to oil leakage, Problems such as large equipment volume, to achieve the effect of stable and reliable measurement data, avoiding vibration influence, and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

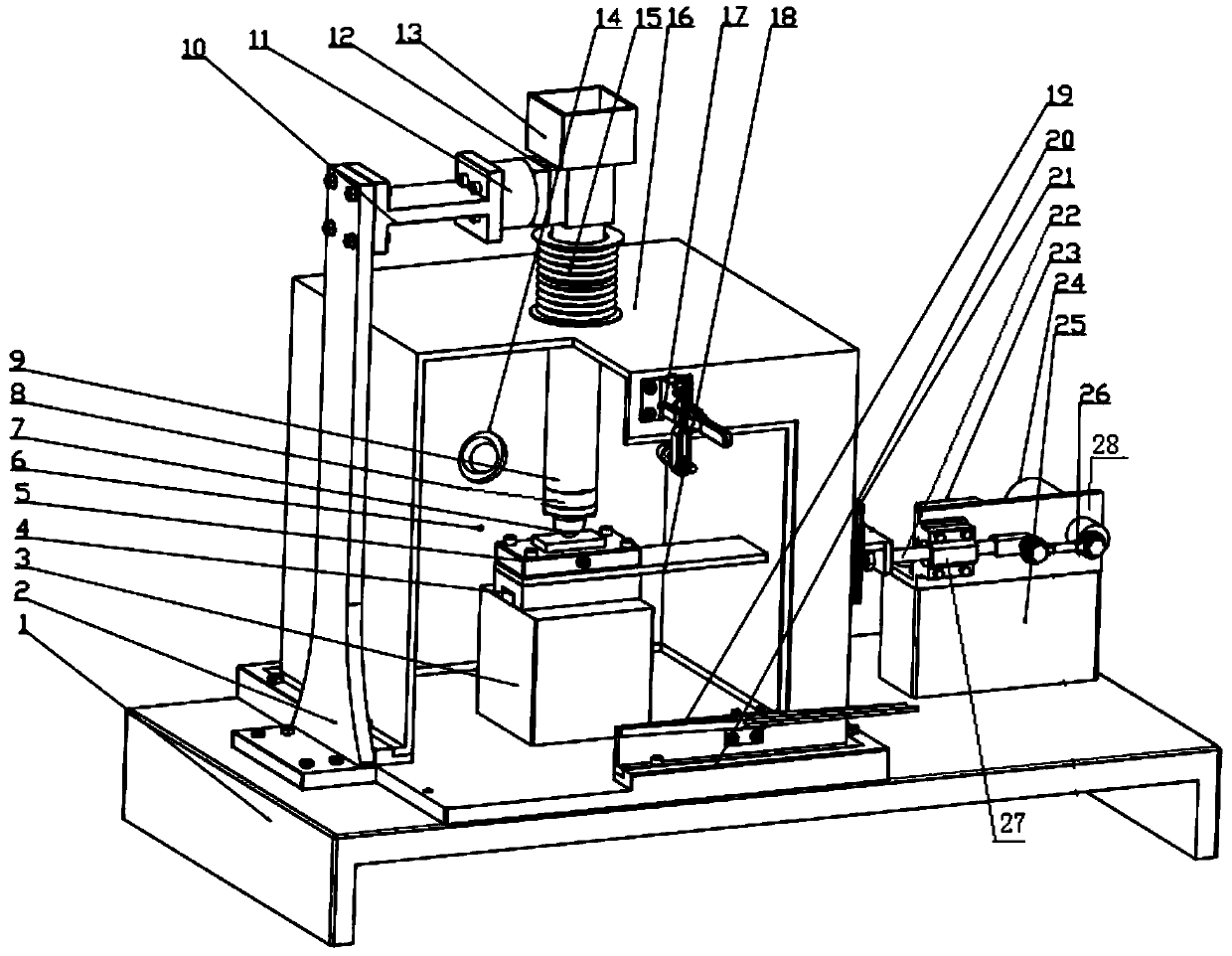

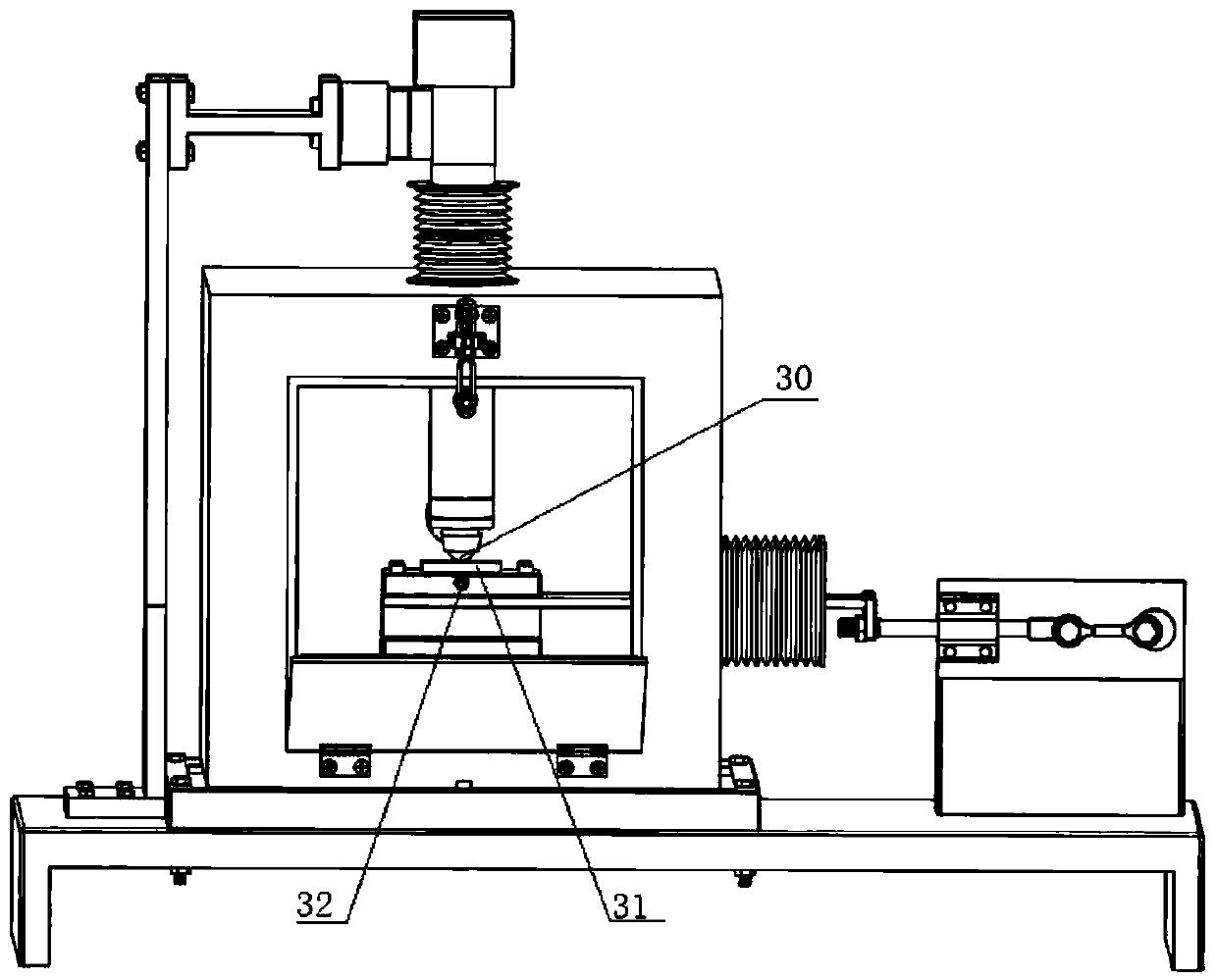

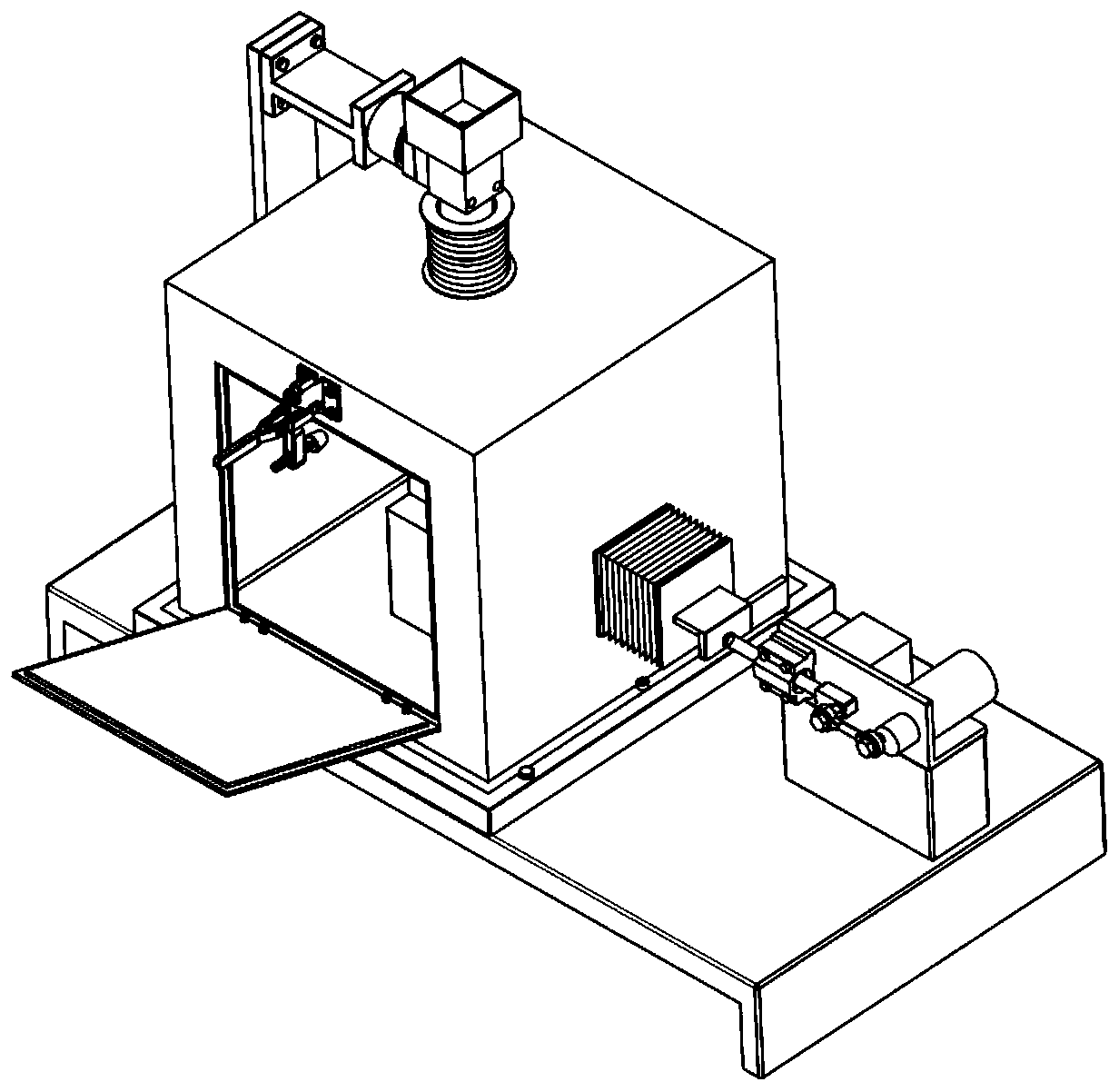

[0024] Embodiment 1: as Figure 1-Figure 4 As shown, a reciprocating corrosion fretting wear tester includes a bottom plate 20, a salt spray chamber 16, a vertical loading device and a lateral movement device. , the middle part of the bottom plate 1 is fixedly connected with the support block 3, the guide rail bar of the horizontal linear guide rail 4 is fixedly connected with the support block 3, the slider of the horizontal linear guide rail 4 is connected with a lateral moving device and a lower clamp 5, and the lower end of the vertical loading device is installed in sequence There is a pressure sensor 8 and an upper fixture 7 facing the lower fixture 5. The vertical loading device moves and seals through the top of the salt spray box 16, and the lateral moving device moves and seals through the side wall of the salt spray box 16. The rear side of the salt spray box 16 A salt mist generating port 14 connected to a salt mist device and a salt mist humidity sensor 6 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com