Compaction mechanism of fast-assembling dolly of engine

A technology of clamping mechanism and engine, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc. It can solve problems such as the inability to adjust the clamping force and the fixed car body, etc., to achieve the clamping force maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further detailed explanation through specific implementation mode below:

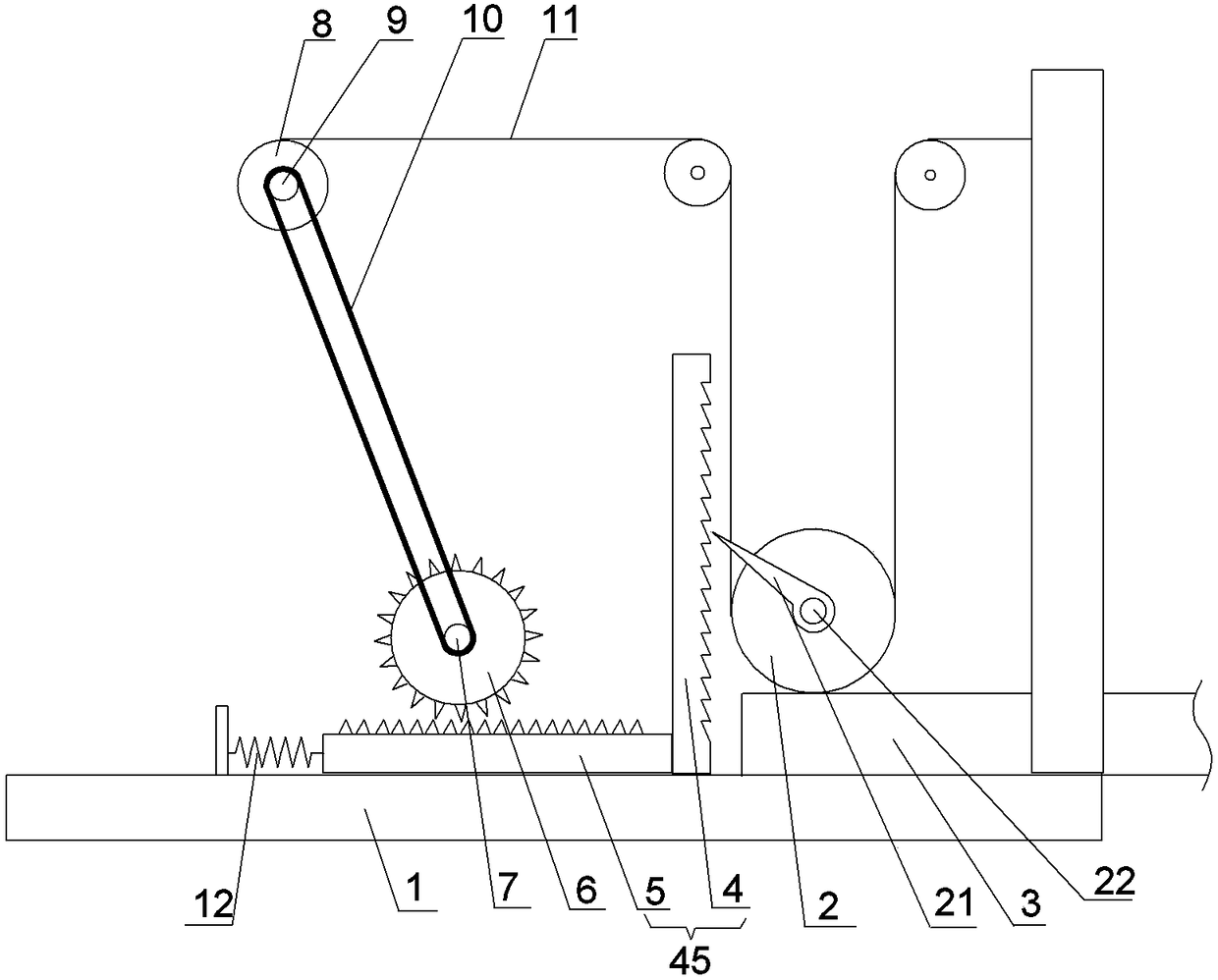

[0025] The reference signs in the drawings of the description include: mounting seat 1, pressing assembly 100, weight 2, ratchet 21, central shaft 22, quick loading trolley 3, ratchet rack 4, straight rack 5, sliding body 45, Gear 6, second rotating shaft 7, rotating wheel 8, first rotating shaft 9, belt 10, transmission belt 11, spring 12.

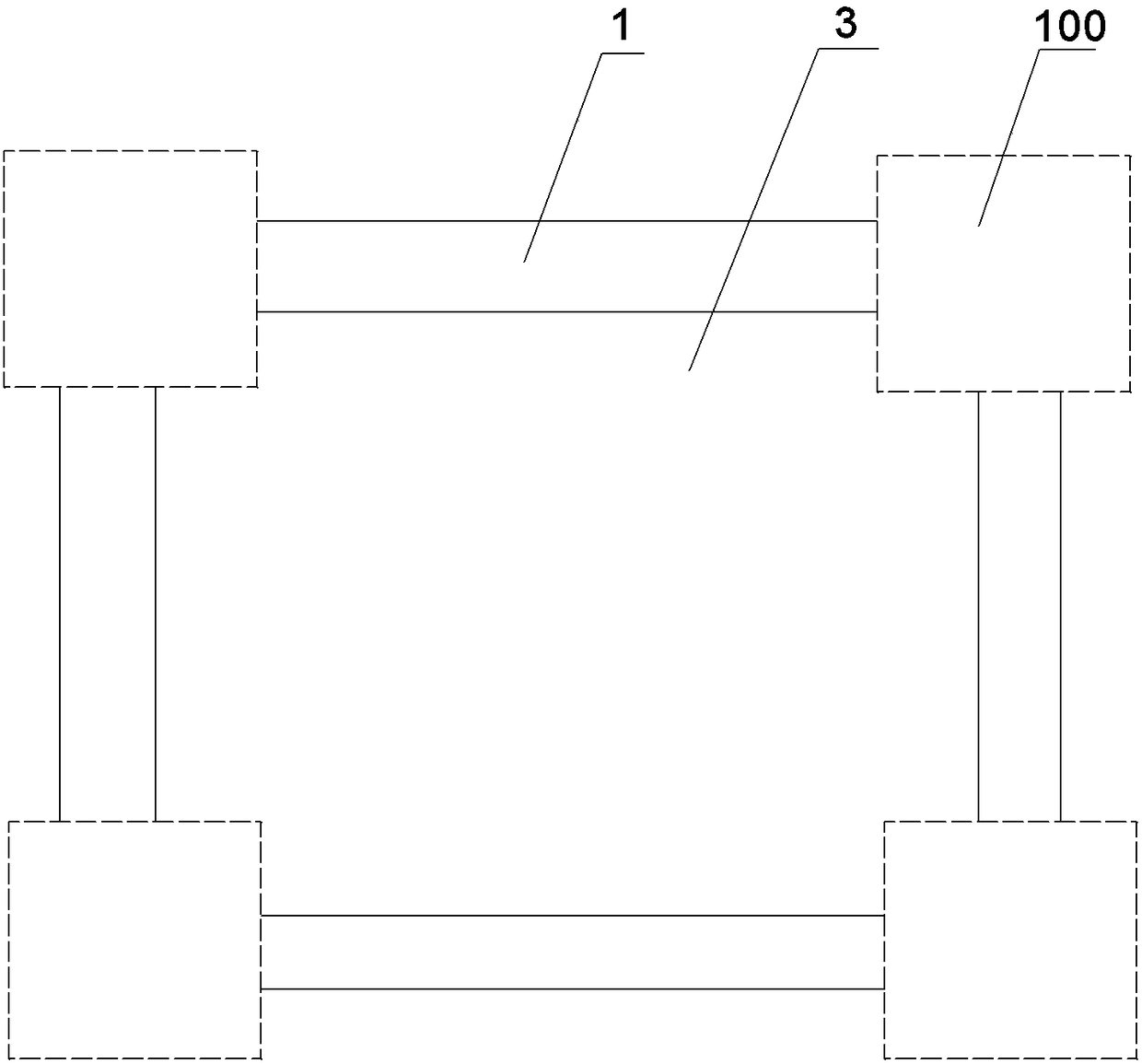

[0026] Such as figure 1 and figure 2 As shown, the compression mechanism of the fast loading trolley for the engine of the present embodiment includes a mounting base 1, and four sets of compression assemblies 100 are arranged above the mounting base 1 to compress the four corners of the fast loading trolley 3, and each set of compression The assembly includes a rotating wheel 8, a transmission belt 11 and a weight 2, the weight 2 is cylindrical, the right end of the transmission belt 11 is fixed on the mounting base 1, the left end is fixed and wound on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com