A compression spring of a snap-in electromagnetic relay

An electromagnetic relay and snap-fit technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as difficult insertion, low assembly efficiency, and difficult shaping, achieve good guiding effects, improve automated assembly, and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

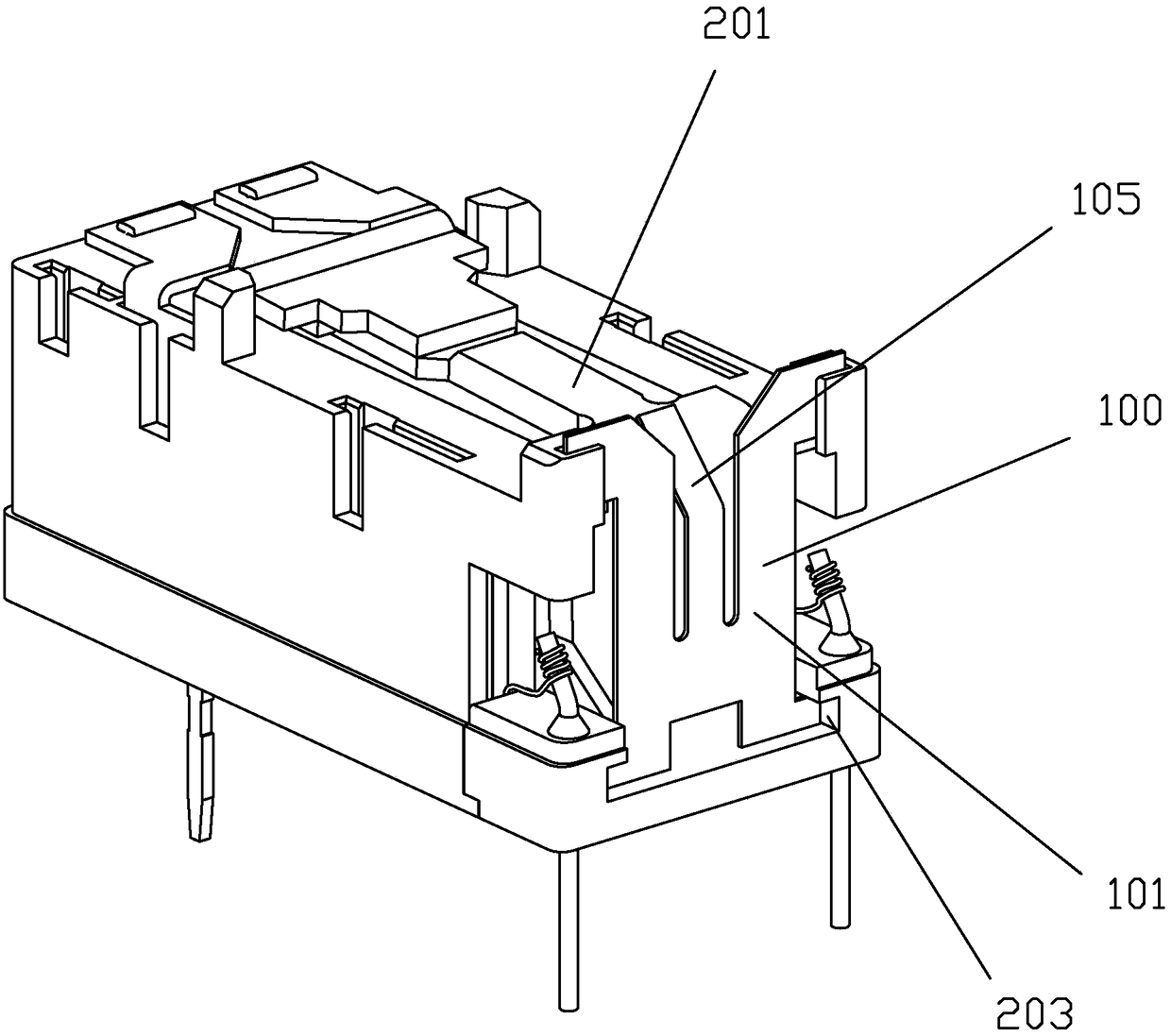

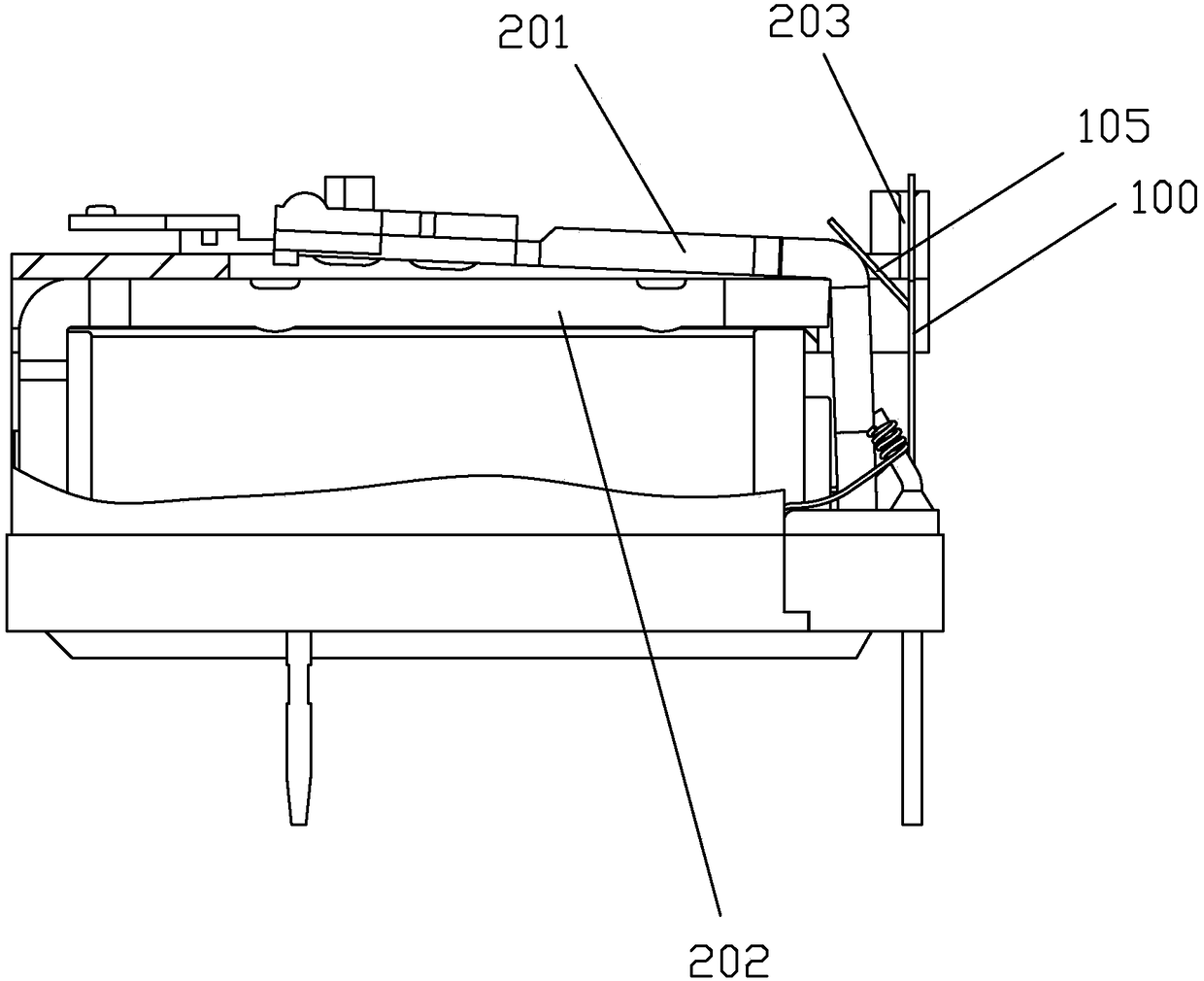

Embodiment 1

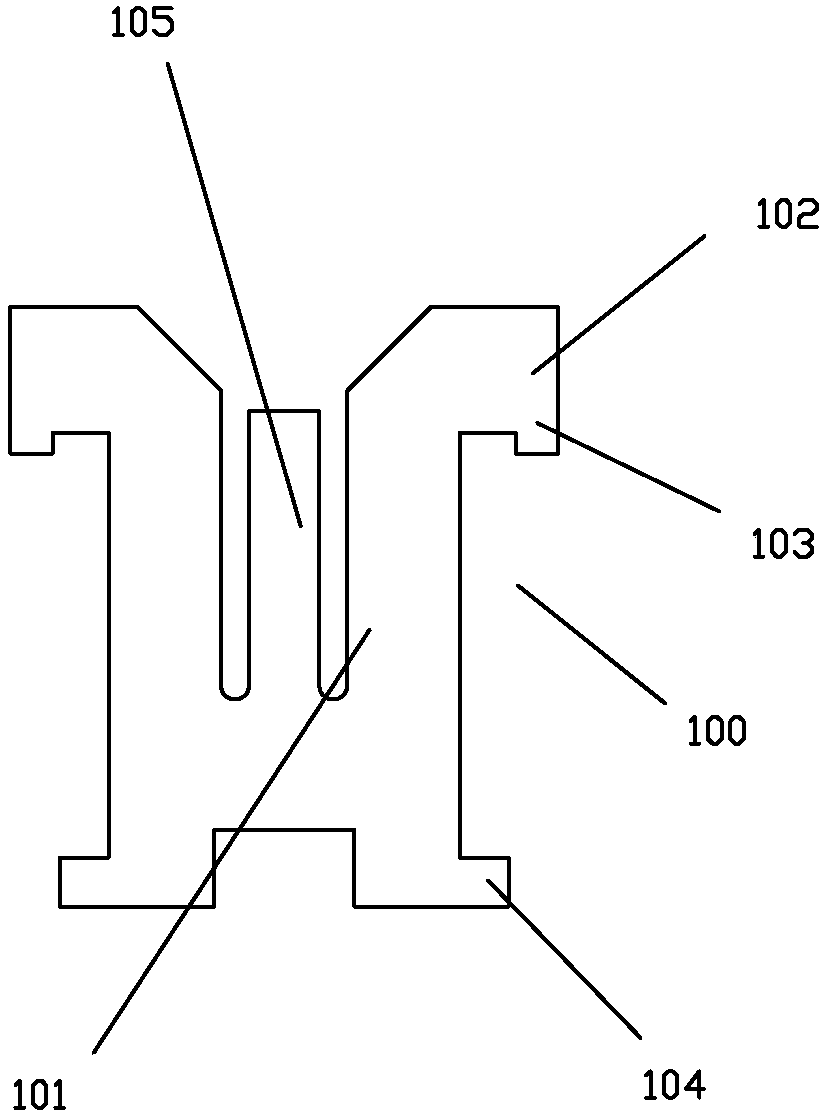

[0045] see Figure 6 to Figure 8As shown, the stage clip of a kind of clapping-type electromagnetic relay of the present invention comprises a main piece body 3 of flat plate shape, and the top of main piece body 3 extends out upper side wing 31 with flat piece mode to both sides, and the terminal end of upper side wing 31 is towards A section of empennage 32 is extended in the form of a flat sheet below, and the lower part of the main sheet body extends a lower wing 33 in a flat sheet manner to both sides, and a tongue sheet 34 forming a certain angle with the plane of the main sheet body is provided in the middle of the main sheet body; The tail fin 32 of the main body is provided with a bending portion 35, so that when the upper wing 31 of the clip spring is inserted into the plastic slot of the relay, the arc surface formed by the bending portion 35 is in contact with the plastic slot of the relay. .

[0046] In this embodiment, the bent portion 35 is an arc structure for...

Embodiment 2

[0054] see Figure 14 to Figure 18 As shown, the stage clip of a clapping type electromagnetic relay of the present invention is different from Embodiment 1 in that the bending portion 35 is located in the middle section of the empennage 32 and is facing away from the tongue of the main body 3. The arc structure 351 protruding from one side of the sheet 34, when the bent part enters the plastic slot, the arc surface of the arc structure 351 contacts the plastic slot 42.

Embodiment 3

[0056] see Figure 19 to Figure 24 As shown, the stage clip of a clapping-type electromagnetic relay of the present invention is different from Embodiment 1 in that the bending direction of the bending portion 35 is different, and the bending portion 35 is the corresponding position of the end of the empennage 32 to the main body 3. The arc structure formed by bending the side away from the tongue piece, when the bent portion 35 enters the plastic slot, the arc surfaces on both sides of the arc structure contact with the plastic slot 42 respectively.

[0057] In this embodiment, the edge of one side 322 of the empennage also has a burr structure formed when the main body is punched out, and the side 322 of the embossment faces away from the tongue 34 . By setting the direction of the burr in advance when the flat piece of the compression spring is stamped, the burr at the position where the compression spring is paired with the plastic slot turns inward in the opposite directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com