Non-sinusoidal vibration method of continuous casting mold

A continuous casting mold, non-sinusoidal technology, applied in the field of metallurgical continuous casting, can solve problems such as breakouts, cracks on the surface of billets, vibration marks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

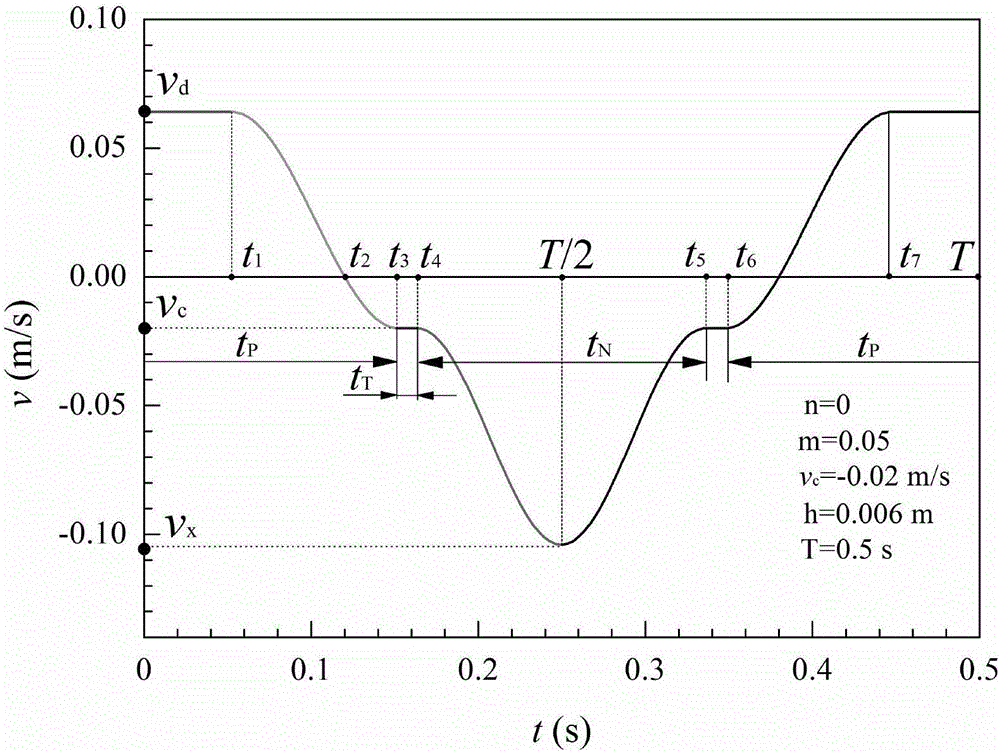

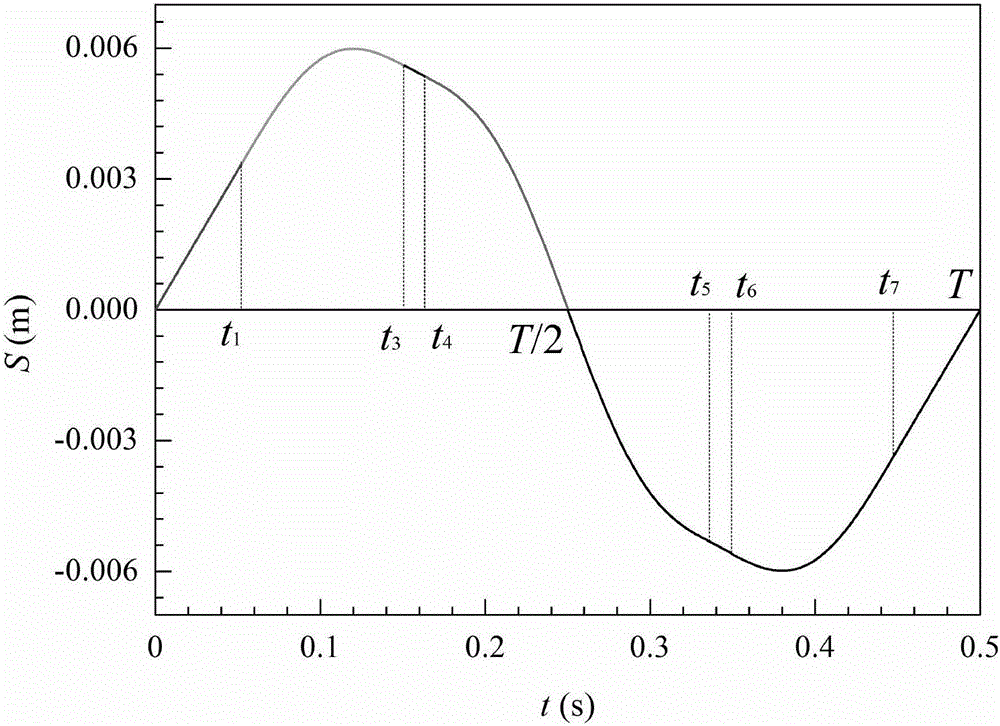

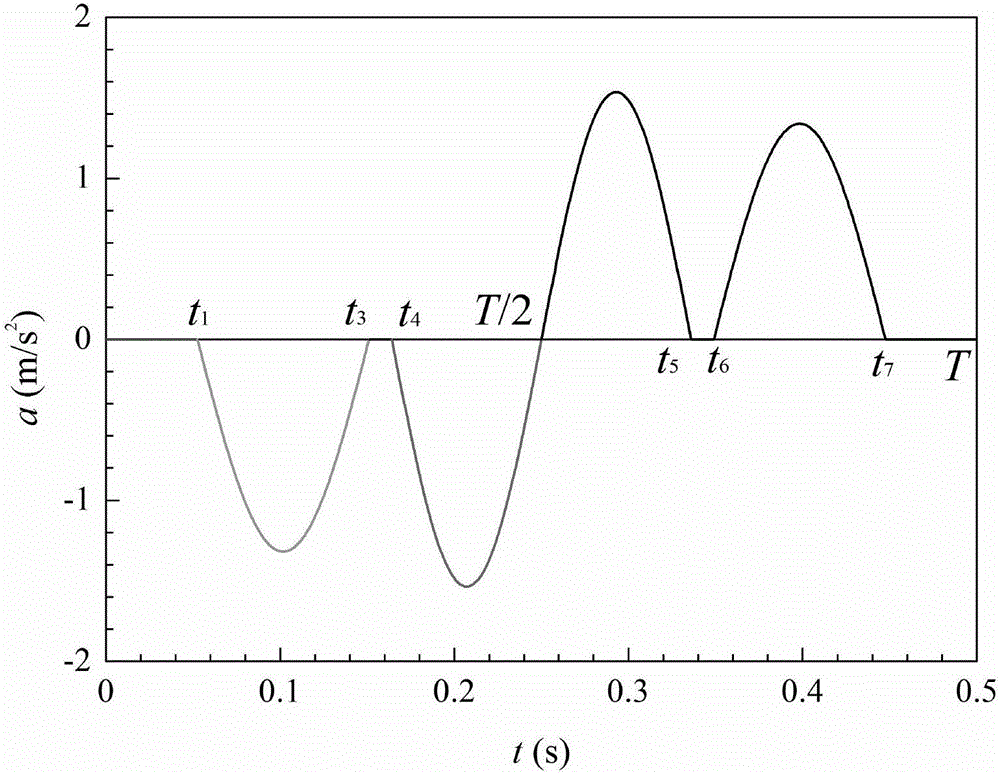

[0032] The specific process of the non-sinusoidal vibration method of the continuous casting mold is: control the driving device of the continuous casting mold, so that the continuous casting mold is driven by the driving device, and the eight-stage speed determined by the following eight-stage speed function in each vibration cycle The waveform vibrates non-sinusoidally:

[0033] v = v d ( 0 ≤ t ≤ t 1 ) v d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com