All-digital variable polarity multifunctional square-wave pulse welding source

A welding power source, square wave pulse technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of improving efficiency and inverter frequency, improving control accuracy and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

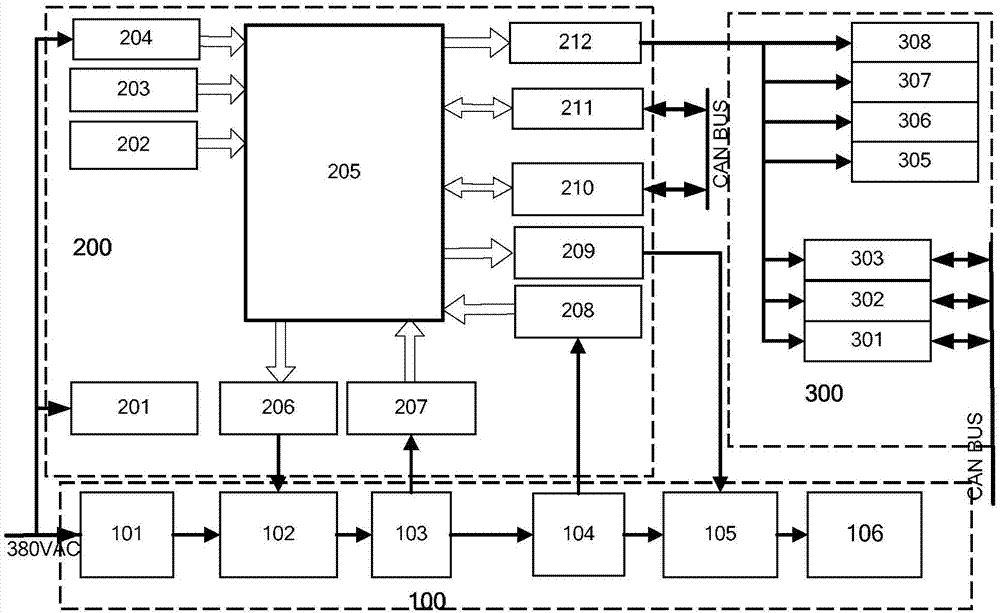

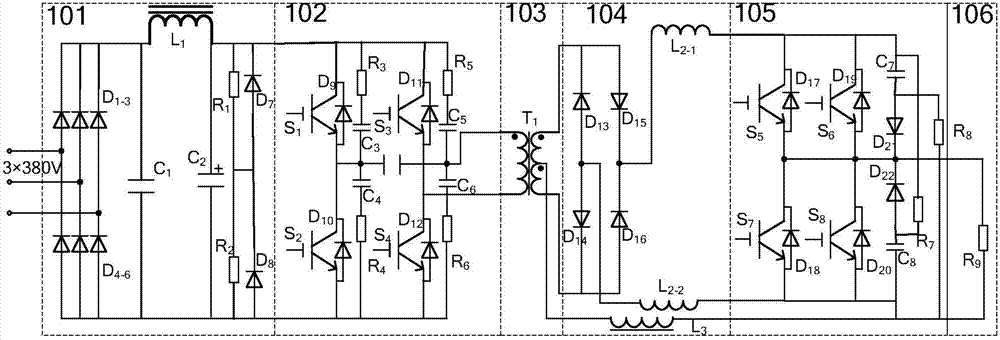

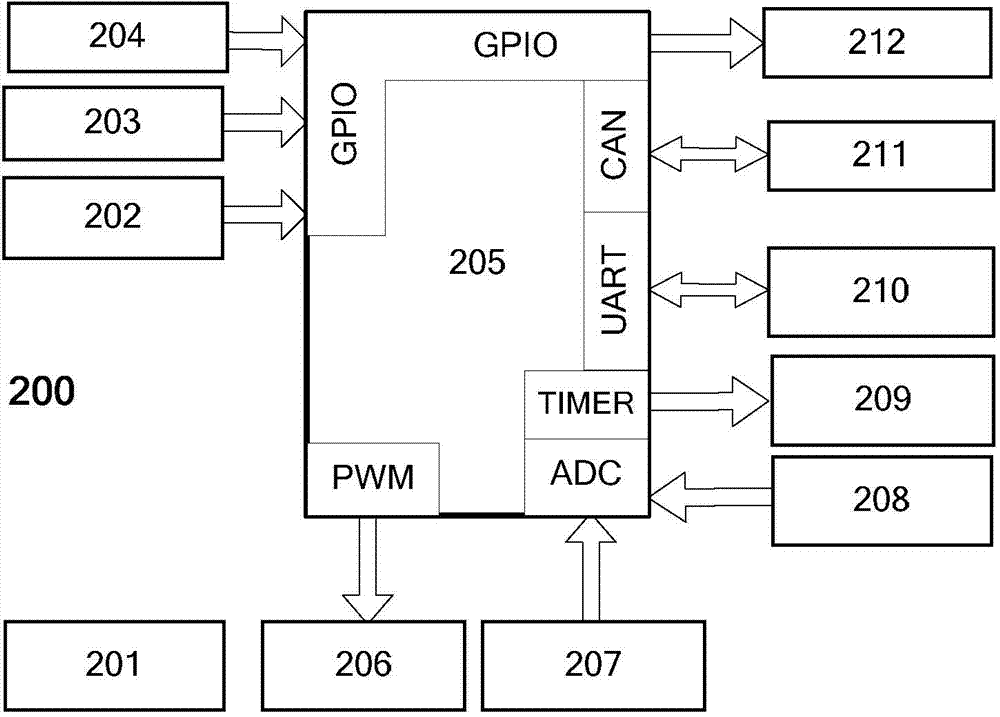

[0026] An all-digital variable polarity multifunctional square wave pulse welding power supply, its system structure diagram is as follows figure 1 shown. The welding power source includes a main circuit 100 and a control circuit 200 . The main circuit 100 includes a rectification and filtering module 101, a front-stage inverter module 102, an intermediate frequency transformer module 103, a fast rectification and filtering module 104, and a rear-stage inverter module 105 connected in sequence; the rectification and filtering module 101 is connected to a three-phase AC input power supply, The rear inverter module 105 is connected to the arc load 106; the front inverter module 102, the intermediate frequency transformer module 103, the fast rectification filter module 104 and the rear inverter module 105 are all connected to the control circuit 200 so as to be controlled by the control circuit 200 Output of welding power source. The welding power supply of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com