Automatic spraying system capable of stabilizing flow

A technology of automatic spraying and stabilizing system, applied in the direction of spraying device, etc., can solve the problems of unstable crystal grain, influence of uniformity of sprayed crucible coating, reduction of polycrystalline efficiency, etc., to ensure uniformity and stability, and realize flexibility The effect of controlling and reducing the cost of polycrystalline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

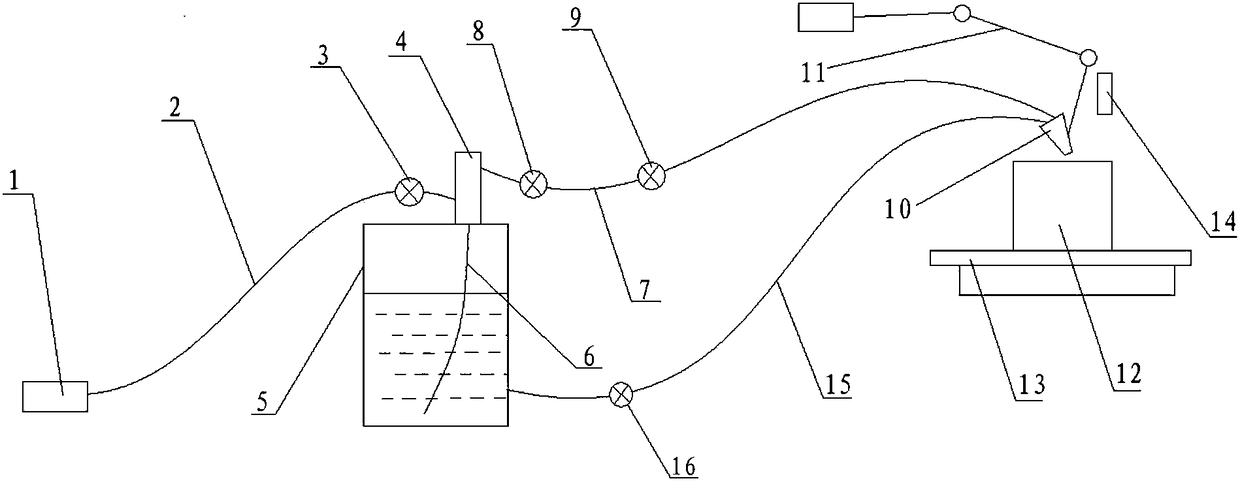

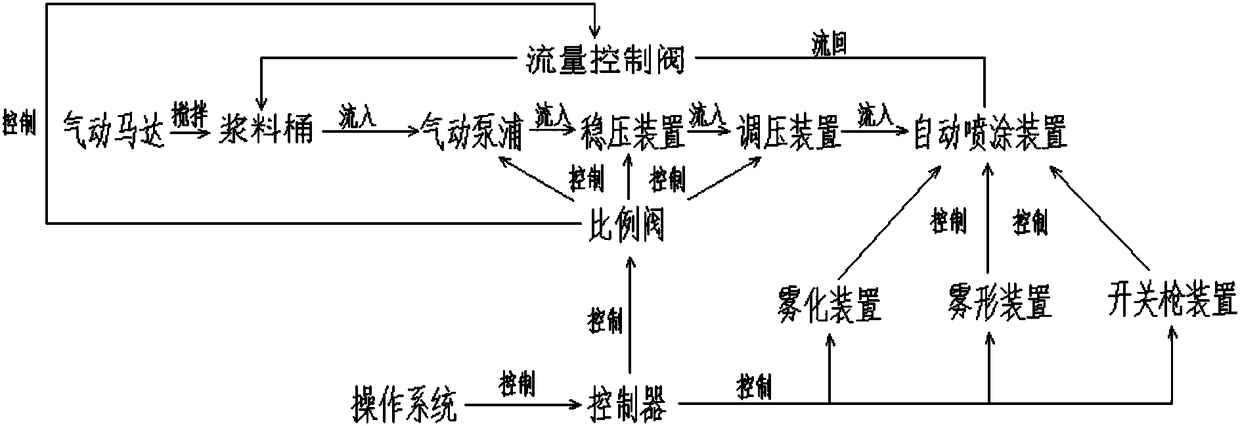

[0027] Such as figure 2 As shown, pure water and silicon nitride powder can be poured into the slurry tank 5 during use, and the slurry can be mixed and stirred by the air motor to drive the agitator until uniform; Adjust the compressed air as the driving air source, use the air pressure difference to extract the slurry from the slurry tank 5 to the output of the delivery pipe 7; control the feeding flow rate of the pneumatic slurry pump 4 by adjusting the air intake and air pressure of the pneumatic slurry pump 4 , the flow rate, flow and pressure of the silicon nitride slurry are flexibly controlled through the proportional valve, the pressure stabilizing valve 8 and the pressure regulating valve 9, so as to ensure the stability of the slurry supply;

[0028] When the crucible is sprayed, the controller controls the mist shape, atomization amount and switch from the atomization port through the atomization solenoid valve, mist shape solenoid valve and switch solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com