Material clamping block for multi-clamp type stretch forming machine

A stretch forming and clamp-type technology, which is applied in the field of clamping blocks for multi-clamp stretch forming machines, can solve the problems of expensive equipment, cracking or wrinkling, and reduced material utilization, so as to improve the quality of materials. Utilization rate, effect of stretch forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

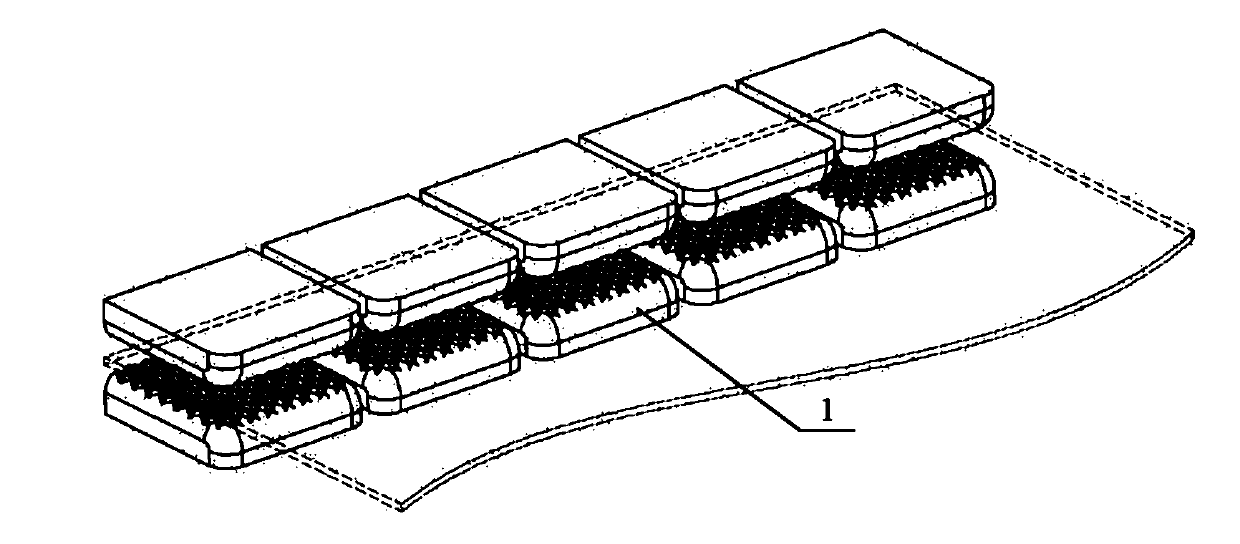

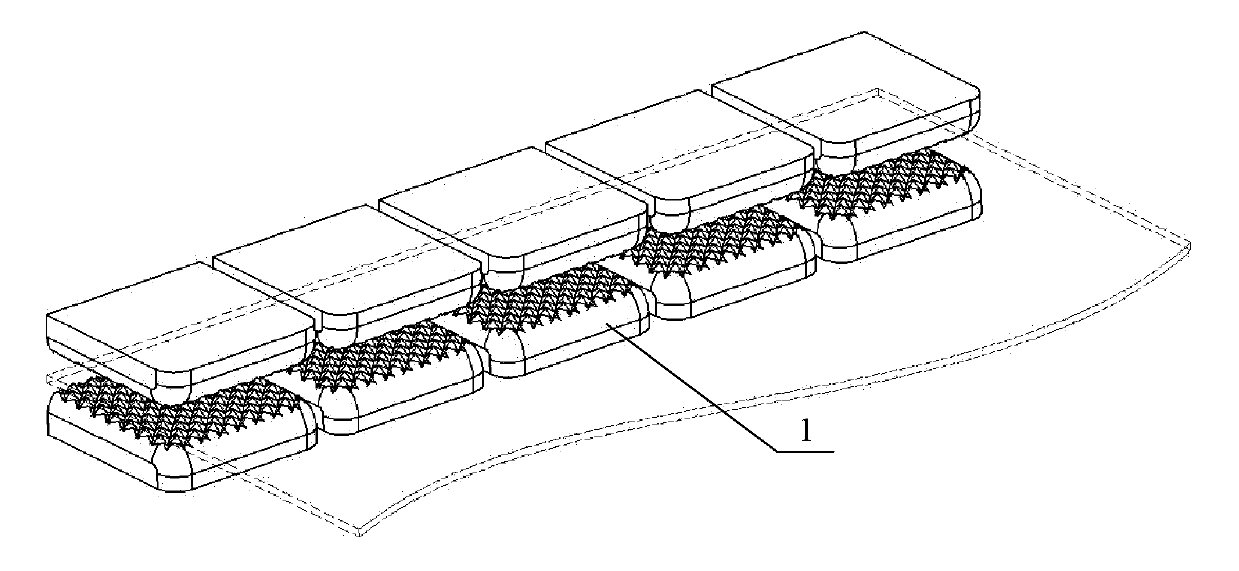

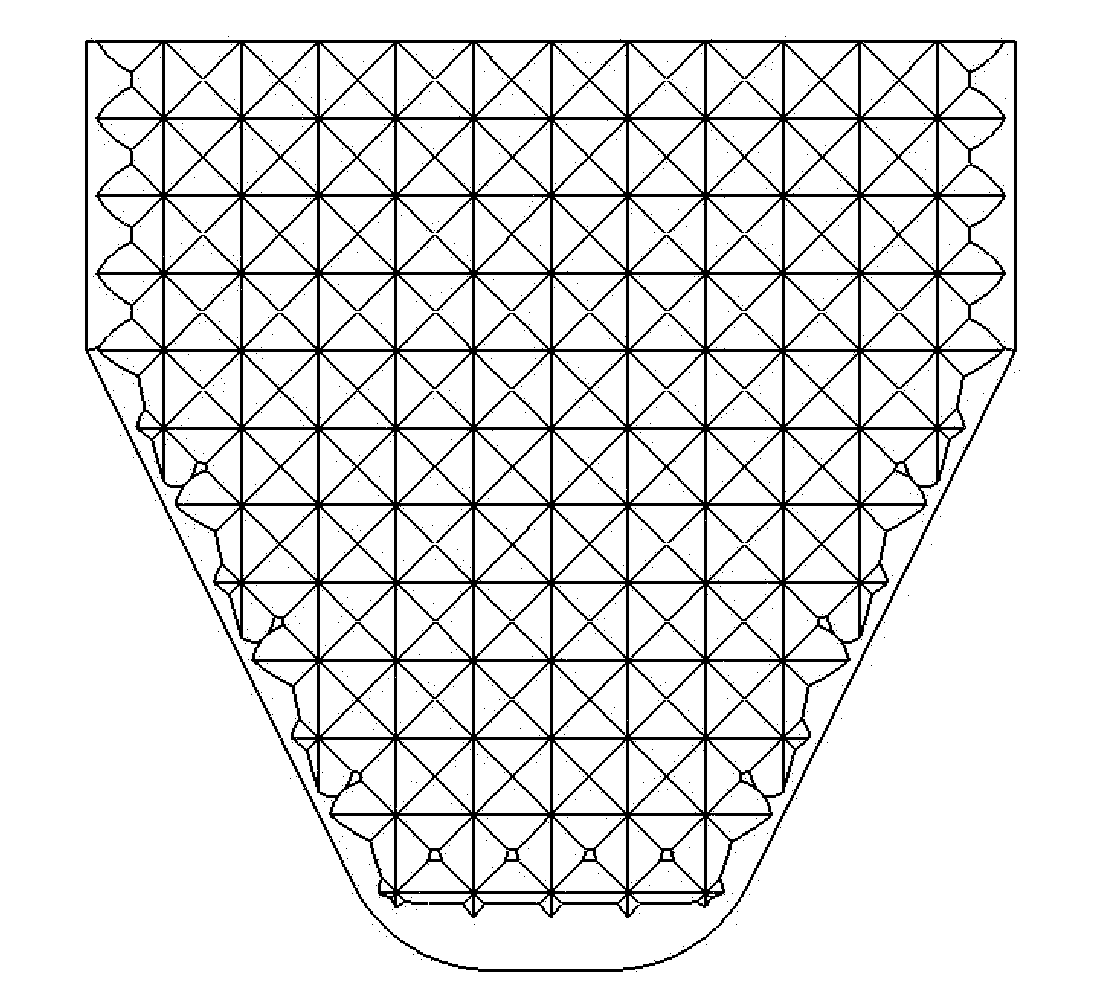

[0023] figure 1 It is a schematic diagram of using multiple pairs of clamping blocks 1 . A row of five pairs of gripping clamping blocks 1 are arranged on the left and right sides of the stretch forming machine respectively; there is a certain gap between the adjacent clamping blocks, and there are Large rounded corners, and there are certain rounded corners at the ridges at the left and right ends of the sandwiching surface adjacent to other sandwiching blocks. In this way, the flow and extension of the sheet material are allowed to occur in places with gaps and rounded corners. The clamping surface adopts a clamping type with many protrusions, which can clamp the sheet material tightly. During the stretch forming process of the sheet metal, the sheet material basically cannot flow in the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com