Pile-driving hydraulic hammer

A technology for piling engineering and hydraulic hammer, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

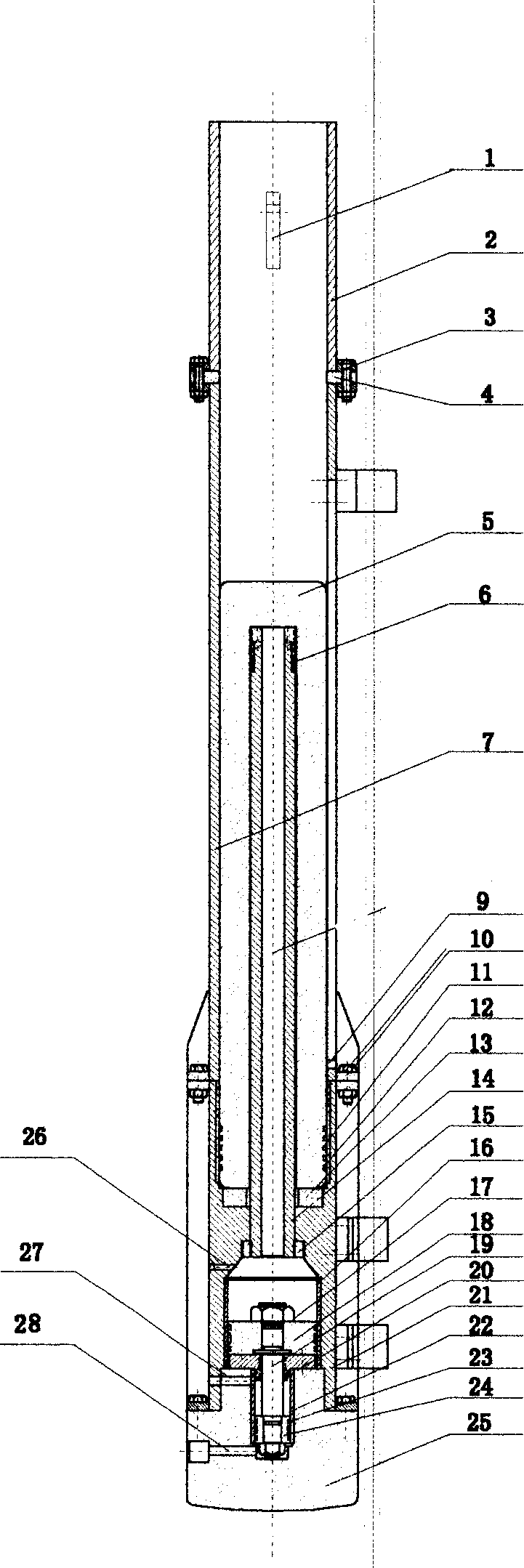

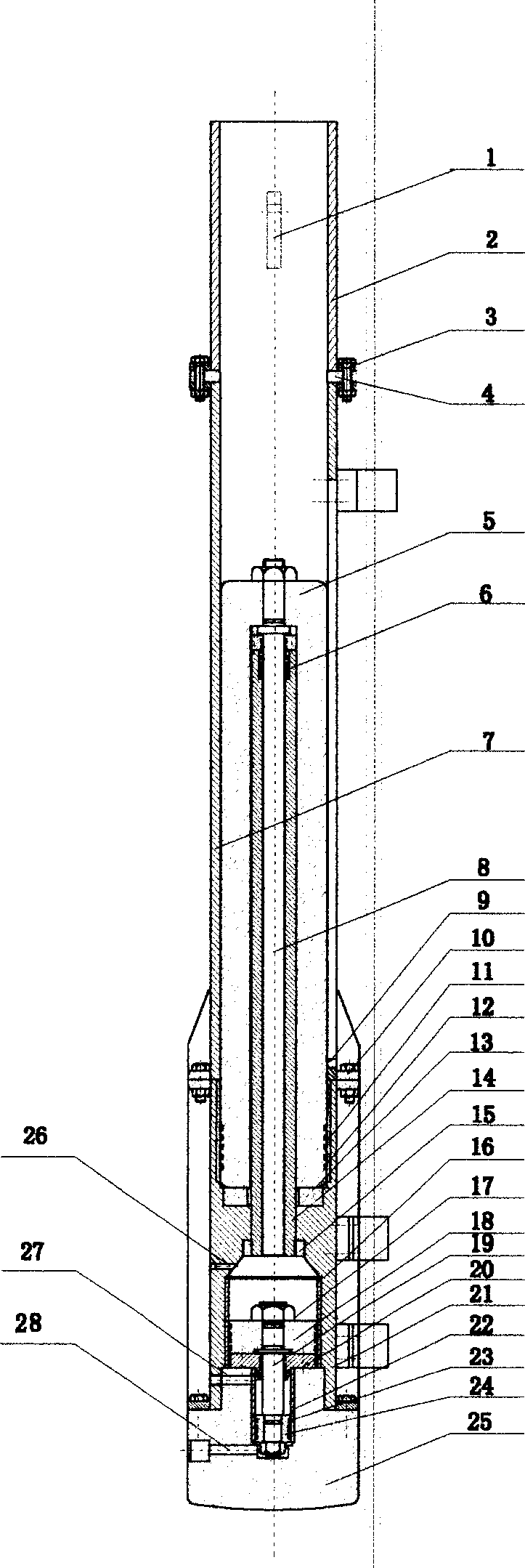

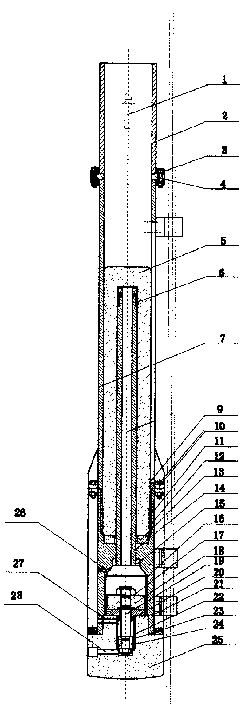

Image

Examples

Embodiment 1

[0010] Embodiment 1 is the same.

[0011] When the present invention works, turn on the starting switch, the electromagnetic valve works, the oil cylinder and the air cylinder of the hydraulic hammer are respectively connected with the external hydraulic source or air pressure source, the machine runs normally, the hydraulic source supplies oil to the oil cylinder 22 through the oil joint 28, and the oil When the pressure increases, the piston 24 is pushed upward, and the piston 24 drives the piston rod 19 and at the same time drives the upper piston 18 to spray the hydraulic oil in the oil cylinder 16 from the oil outlet to the inner long cylinder 14, forcing the piston cylinder hammer 5 to push upward, so that When the piston cylinder hammer 5 speeds up the movement speed to the design height, the solenoid valve switches the oil pressure source to supply oil to the oil cylinder 22 through the oil joint 27, so that the lower piston 24 in the oil cylinder 22 moves downward to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com