Water jet milling concrete-removing robot

A robot and water milling technology, applied in construction, building maintenance, roads, etc., can solve the problems of low automation, narrow application range, and poor adaptability, and achieve high automation, convenient and fast connection, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

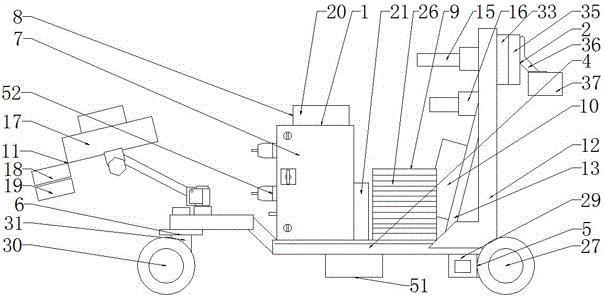

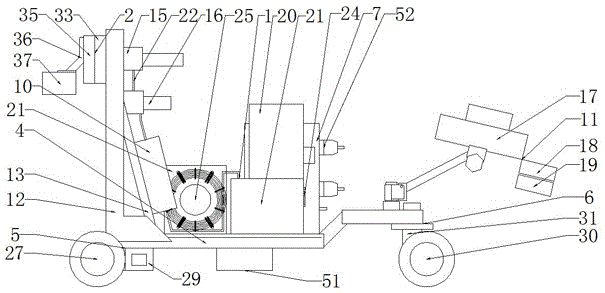

[0060] as attached Figure 1-23 As shown, the water milling concrete removal robot includes a fuselage 1 and a telescopic arm 2. The fuselage 1 is composed of a protective cover 3, a chassis 4, a front drive system 5, a rear steering system 6, a distribution box 7, and a power system 8 , cooling system 9, solenoid valve group 10, control system 11, support frame 12;

[0061] The right end of the chassis 1 is provided with a support frame 12, an oblique support 13 is provided between the chassis 1 and the support frame 12, a front drive system 5 is provided below the right end of the chassis 1, and the left end side of the upper side of the chassis 1 is A power system 8 is provided, a power distribution box 7 is provided on the other side of the left end of the upper side of the chassis 1, a solenoid valve group 10 is provided on one side above the middle of the chassis 1, and a cooling system is provided on the other side above the middle of the chassis 1 9. The left end of t...

Embodiment 2

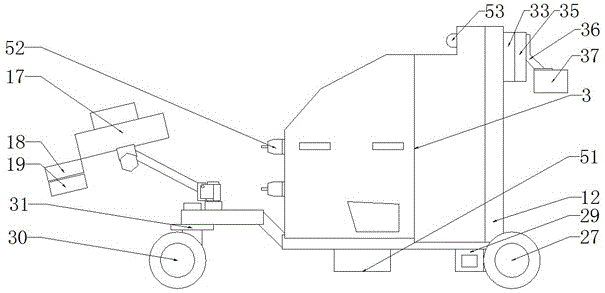

[0087] as attached Figure 10 As shown, the present invention can adjust the telescopic arm to carry out water milling operation on the concrete lower surface below the wheel plane, and its maximum working depth can reach 0.65 meters below the wheel plane. Water milling avoids building scaffolding from the bottom of the bridge for operation, which greatly saves time, manpower, material resources, saves costs, and speeds up production progress.

Embodiment 3

[0089] as attached Figure 11 As shown, the present invention can perform water milling and concrete removal operations on the vertical surface below the wheel plane, and its maximum working depth can reach 3.3 meters below the wheel plane. For example, the robot is placed on the top of the dam to perform water milling on the side of the dam Concrete operation, convenient and quick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com