Polyolefin communication cable material used in rail transportation, and preparation method thereof

A rail transit and polyolefin technology, which is applied in the field of material chemistry, can solve the problems of insufficient water resistance, barrier resistance, scratch resistance and flexibility, complex preparation process, and inability to recycle, and achieve excellent physical and mechanical properties, good processing fluidity, The effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

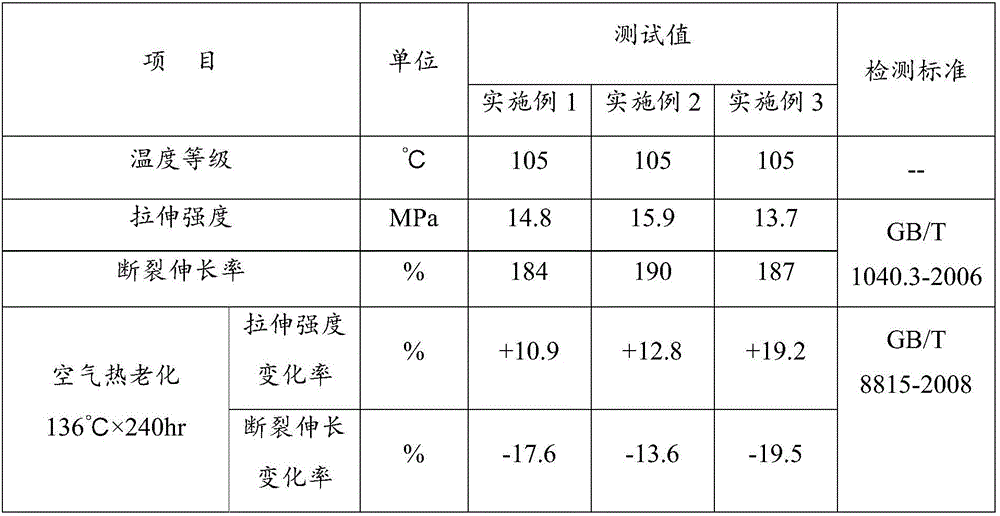

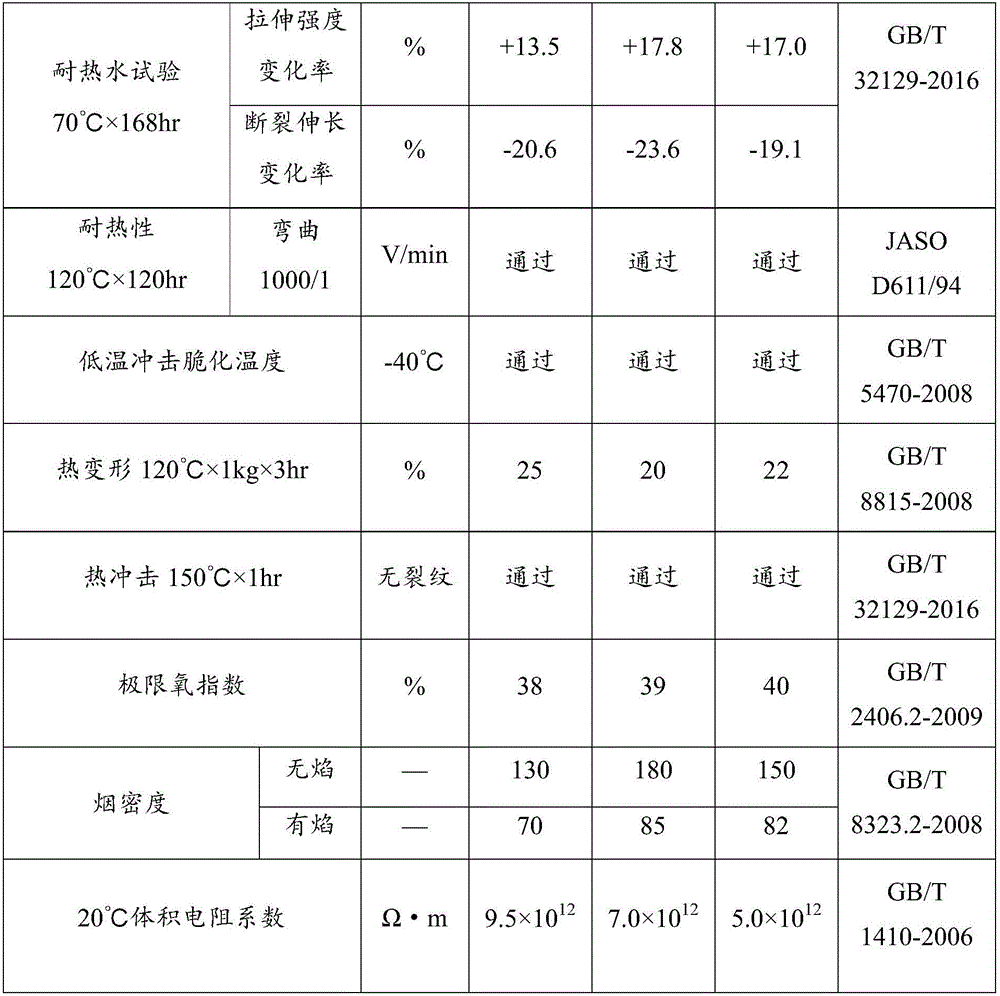

Embodiment 1

[0023] A polyolefin communication cable material for rail transit, which is composed of the following components in proportion by weight: 40 parts of ethylene-vinyl acetate copolymer, 50 parts of propylene-ethylene block copolymer, 10 parts of interface compatibilizer, 160 parts of flame retardant, 2 parts of composite antioxidant, 5 parts of anti-wear agent, 1 part of ultraviolet absorber, 2 parts of lubricant, 2 parts of water blocking agent, and 1 part of metal deactivator.

[0024] The ethylene-vinyl acetate copolymer is two kinds of ethylene-vinyl acetate copolymers whose vinyl acetate monomer dosages are 28wt% and 40wt%, mixed at 1:1, and the melt flow rate is 3g / 10min; the propylene -The molar content of ethylene in the ethylene block copolymer is 12%, and the melt flow rate is 2.5g / 10min; the interface compatibilizer is polypropylene polar monomer graft, and the polar monomer is maleic acid Acid anhydride, the graft content is 1.0wt%.

[0025] The flame retardant is m...

Embodiment 2

[0037] A polyolefin communication cable material for rail transit, which is composed of the following components in proportion by weight: 45 parts of ethylene-vinyl acetate copolymer, 40 parts of propylene-ethylene block copolymer, 15 parts of interface compatibilizer, 170 parts of flame retardant, 2 parts of composite antioxidant, 5 parts of antiwear agent, 1 part of ultraviolet absorber, 2 parts of lubricant, 2 parts of water blocking agent, and 1 part of metal deactivator.

[0038] The ethylene-vinyl acetate copolymer is two kinds of ethylene-vinyl acetate copolymers whose vinyl acetate monomer dosages are 28wt% and 40wt%, mixed at 1:1, and the melt flow rate is 3g / 10min; the propylene -The molar content of ethylene in the ethylene block copolymer is 10%, and the melt flow rate is 2.5g / 10min; the interface compatibilizer is polypropylene polar monomer graft, and the polar monomer is maleic acid Acid anhydride, the graft content is 1.0wt%.

[0039] The flame retardant is mi...

Embodiment 3

[0051] A polyolefin communication cable material for rail transit, which is composed of the following components in proportion by weight: 50 parts of ethylene-vinyl acetate copolymer, 40 parts of propylene-ethylene block copolymer, 10 parts of interface compatibilizer, 180 parts of flame retardant, 2 parts of composite antioxidant, 5 parts of anti-wear agent, 1 part of ultraviolet absorber, 2 parts of lubricant, 2 parts of water blocking agent, and 1 part of metal deactivator.

[0052] The ethylene-vinyl acetate copolymer is two kinds of ethylene-vinyl acetate copolymers whose vinyl acetate monomer dosages are 28wt% and 40wt%, mixed at 1:1, and the melt flow rate is 3g / 10min; the propylene -The molar content of ethylene in the ethylene block copolymer is 8%, and the melt flow rate is 2.0g / 10min; the interface compatibilizer is polypropylene polar monomer graft, and the polar monomer is maleic acid Acid anhydride, the graft content is 1.0wt%.

[0053] The flame retardant is mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com