Electromagnetic pulse welding method of multilayer battery aluminum plate lugs and copper pole lugs

A technology of electromagnetic pulse and welding method, which is applied in the direction of high-frequency current welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of consumption of welding auxiliary materials, high welding cost, high energy consumption, etc., to improve production efficiency, The effect of reducing labor intensity and no consumption of auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

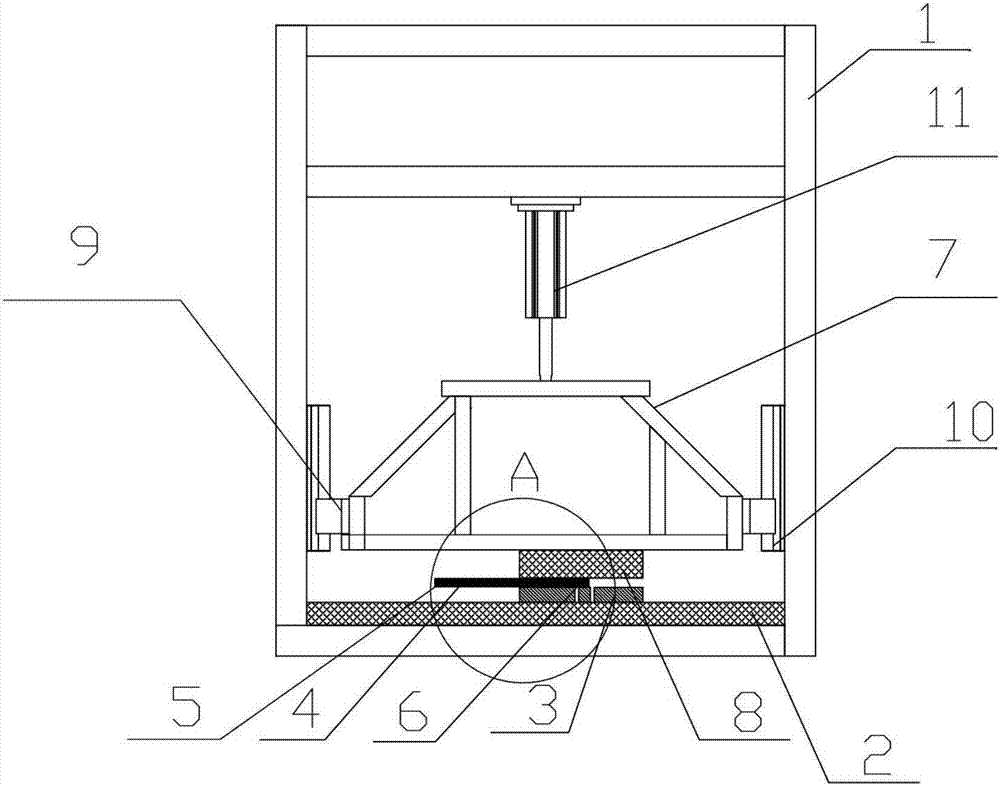

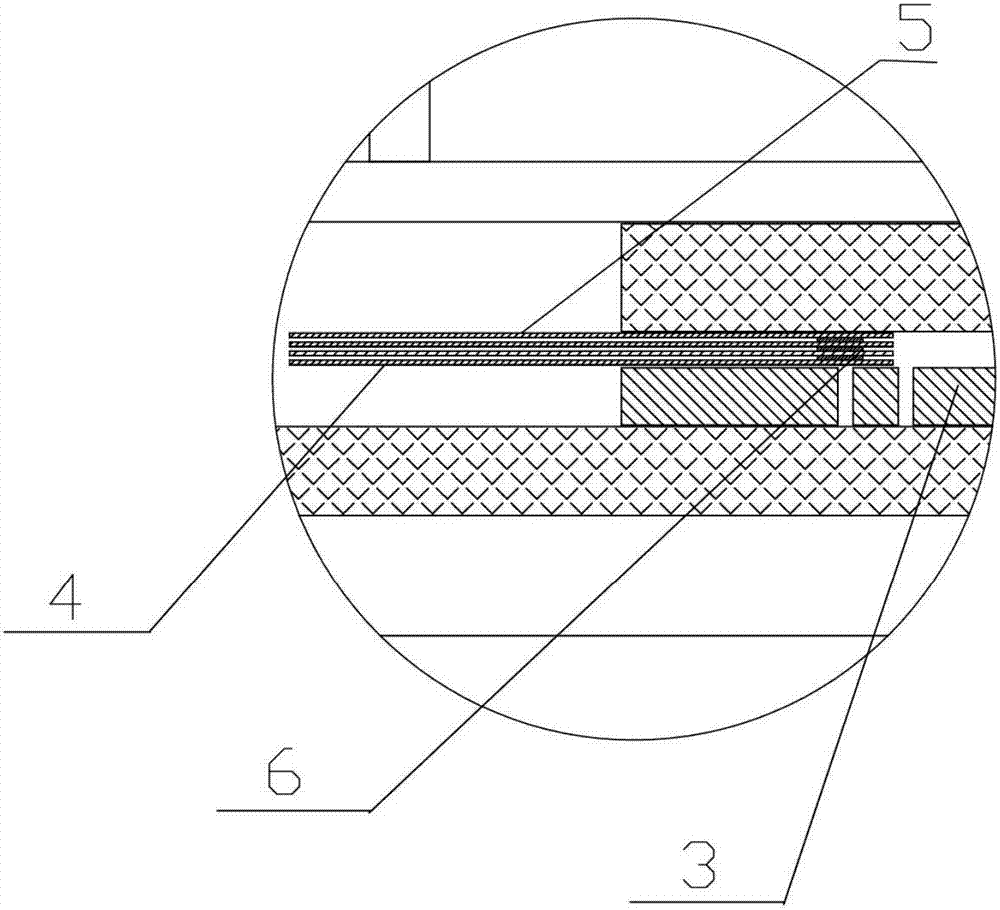

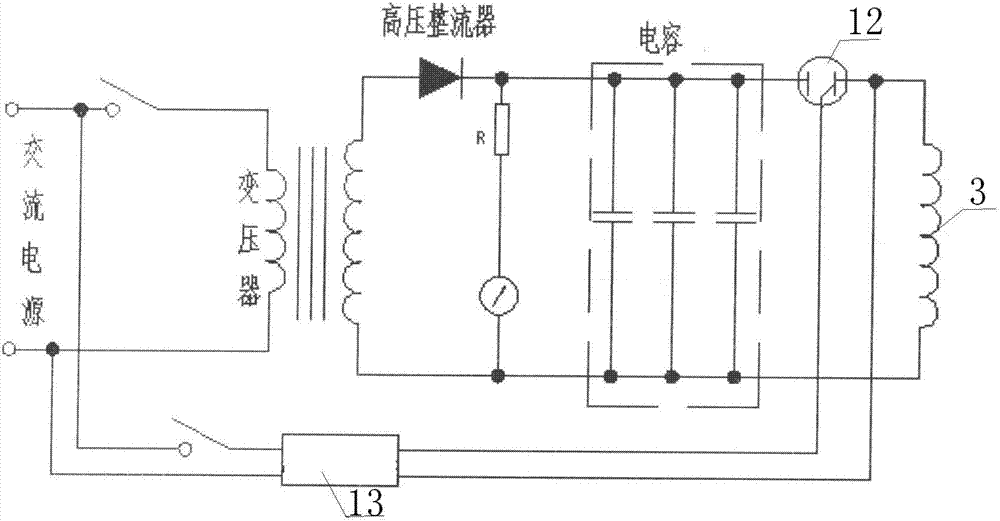

[0023] Example 1, such as Figure 1-3 Shown: The electromagnetic pulse welding method of aluminum lugs and copper lugs of a multi-layer battery, including the steps of fixing the aluminum lugs 4 and copper lugs 5 on the welding device. The welding device includes a frame, and the frame 1 is provided with a backing plate 2 , the electromagnetic coil 3 is set on the backing plate 2, and the welding area of the multi-layer aluminum plate ear 4 is placed on the electromagnetic coil 3, here is a three-layer aluminum plate ear 4, and a copper pole ear 5 is placed above the uppermost aluminum plate ear 4, and the aluminum plate ear 4 A gap piece 6 is provided between the welding areas and between the aluminum tab 4 and the copper tab 5 , and the aluminum tab 4 and the copper tab 5 are fixed by a pressing plate 8 . Preferably, a platen frame 7 is arranged above the backing plate 2, and the platen 8 is installed on the lower surface of the platen frame 7, and the platen frame 7 is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com