A kind of method for producing fuel ethanol by fermentation of koji distiller's grains

A technology for fuel ethanol and koji distiller's grains, which is applied in the directions of microorganism-based methods, biofuels, biochemical equipment and methods, etc., can solve problems such as solid waste environmental pollution, and achieve the effect of reducing steam consumption and solving pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

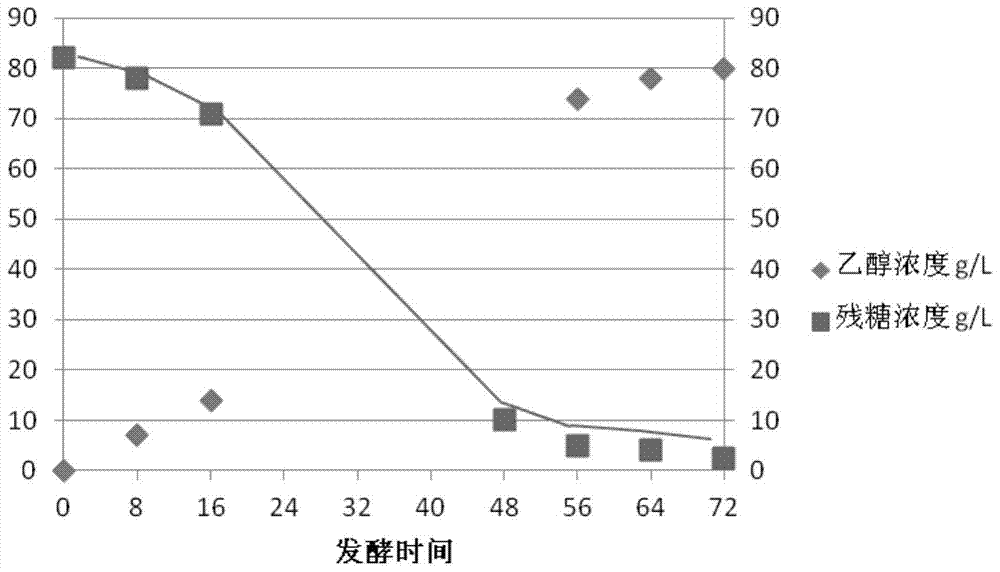

Image

Examples

Embodiment 1

[0018] A method for producing fuel ethanol by fermenting koji distiller's grains, comprising the following steps:

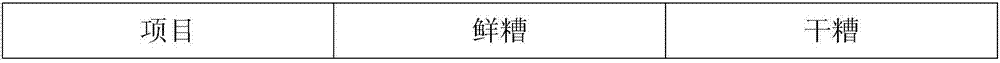

[0019] Distiller's grains routine testing component results unit g / 100g

[0020]

[0021]

[0022] 1. Pretreatment of koji distiller's grains:

[0023] The distiller's grains are dried and pulverized, and placed in a 3L fermentation bottle to meet the concentration requirements of raw material pulverization and emulsification in the thick mash fermentation process. Stir evenly at the same time, put it into a steam sterilizer for high-temperature hydrolysis, and then reduce the pressure. Lower the temperature, take it out and cool it down to 50°C and add complex enzymes for enzymatic hydrolysis and saccharification.

[0024] 2. Compound enzymatic hydrolysis, liquefaction and saccharification:

[0025] The synergistic effect of enzymes is like a "relay race", for example, coarse starch generates a large amount of dextrin under the action of high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com