Preparation method of degradable strapping tape material

A technology for tape materials and preparation steps, which is applied in the field of preparation of degradable cable ties, can solve the problems of difficult control of degradation cycle and poor heat resistance, and achieve the effects of easy control of degradation cycle, chemical corrosion resistance and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

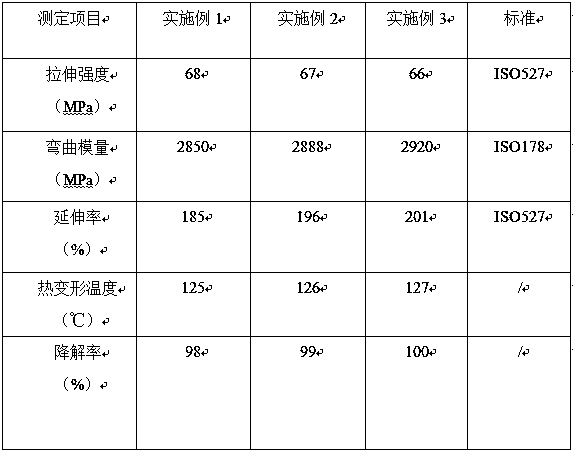

Examples

Embodiment 1

[0027] Dry polylactic acid in an oven at 40°C to constant weight and cool to room temperature to obtain dry polylactic acid. Place the dry polylactic acid in ST / RI pulsed atmospheric pressure plasma equipment and place it horizontally at the lower end to block The surface of the medium, the electrode material is copper-nickel composite material, the electrode area is 25cm×25cm, the plate spacing is 2mm, the two electrodes are embedded in the glass barrier medium with a thickness of 2mm, and the plasma treatment is performed at a discharge power of 50W for 3 minutes. Modified polylactic acid; according to the mass ratio of 1:5, mix the modified polylactic acid and the acrylic acid aqueous solution with a mass fraction of 50%, and stir for 10 minutes at a stirring speed of 200r / min to obtain a dispersion, and filter to obtain a filter residue. Mix the filter residue and deionized water at a ratio of 1:10, stir at 80°C for 2 hours to obtain a mixed material, add a 10% sodium hydro...

Embodiment 2

[0029] Dry polylactic acid in an oven at 43°C to constant weight, and cool to room temperature to obtain dry polylactic acid. Place the dry polylactic acid in ST / RI pulsed atmospheric pressure plasma equipment and place it horizontally at the lower end to block The surface of the medium, the electrode material is copper-nickel composite material, the electrode area is 25cm×25cm, the plate spacing is 4mm, the two electrodes are embedded in the glass barrier medium with a thickness of 2mm, and the plasma treatment is performed at a discharge power of 55W for 4min. Modified polylactic acid; according to the mass ratio of 1:5, the modified polylactic acid and the mass fraction of 50% acrylic acid aqueous solution were mixed, stirred at a stirring speed of 250r / min for 13min, and the dispersion liquid was obtained, and the filter residue was obtained by filtering. Mix the filter residue and deionized water at 1:10, stir at 90°C for 3 hours to obtain the mixed material, add 10% sodiu...

Embodiment 3

[0031] Dry polylactic acid in an oven at 45°C to constant weight, and cool to room temperature to obtain dry polylactic acid. Place the dry polylactic acid in ST / RI pulsed atmospheric pressure plasma equipment and place it horizontally at the lower end to block The surface of the medium, the electrode material is copper-nickel composite material, the electrode area is 25cm×25cm, the plate spacing is 6mm, the two electrodes are embedded in the glass barrier medium with a thickness of 2mm, and the plasma treatment is performed at a discharge power of 60W for 5min. Modified polylactic acid; according to the mass ratio of 1:5, mix the modified polylactic acid and the acrylic acid aqueous solution with a mass fraction of 50%, and stir for 15 minutes at a stirring speed of 300r / min to obtain a dispersion, and filter to obtain a filter residue. Mix the filter residue and deionized water at a ratio of 1:10, stir for 4 hours at a temperature of 100°C to obtain a mixed material, add a 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com