Antirust paint added with magnet powder for food production machine

A technology for producing machinery and magnet powder, which is applied in the field of antirust paint, which can solve the problems of poor corrosion resistance, slow drying, and poor antirust ability, and achieve the effects of low kinematic viscosity, tight polymerization, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

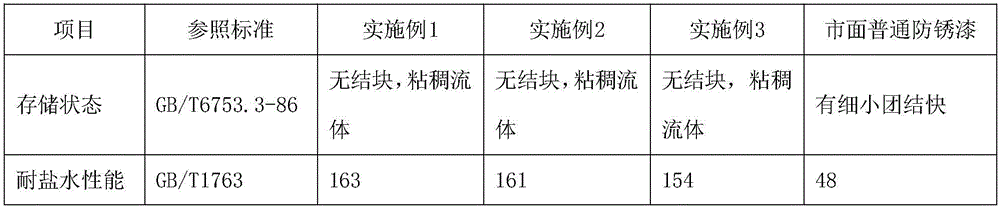

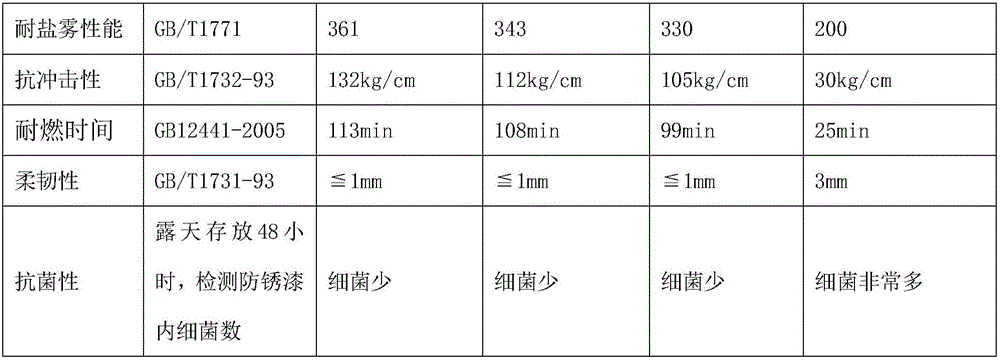

Examples

Embodiment 1

[0013] An antirust paint for food production machinery added with magnet powder, made of the following raw materials in parts by weight: 31 parts of acrylic emulsion, 5 parts of dimethyl silicone oil, 8 parts of oxaloacetic acid, 5 parts of isocitric acid, benzoic acid ring 5 parts of hexylamine, 13 parts of boric acid, 1.5 parts of medical chalk, 1.5 parts of dibenzothiazole disulfide, 1 part of catechin, 4 parts of modified magnetite powder.

[0014] The polymerized graphene oxide is made of the following raw materials in parts by weight: 8 parts of magnetite powder, 1.5 parts of glyceraldehyde-3-phosphate, 0.8 parts of dibutyltin dilaurate, 2.5 parts of α-terpineol, 1-butyl- 0.4 part of 3-methylimidazole chloride, 0.4 part of carboxymethyl cellulose, and 0.4 part of guar gum ether; the preparation method is as follows: mixing the raw materials and stirring evenly at 1200 rpm.

[0015] A preparation method for antirust paint for food production machinery adding magnetite pow...

Embodiment 2

[0019] An antirust paint for food production machinery added with magnet powder, made of the following raw materials in parts by weight: 30 parts of acrylic emulsion, 4 parts of simethicone oil, 6 parts of oxaloacetic acid, 4 parts of isocitric acid, benzoic acid ring 4 parts of hexylamine, 10 parts of boric acid, 1 part of medical chalk, 1 part of dibenzothiazole disulfide, 0.5 parts of catechin, 3 parts of modified magnetite powder.

[0020] The polymerized graphene oxide is made of the following raw materials in parts by weight: 5 parts of magnetite powder, 1 part of glyceraldehyde-3-phosphate, 0.6 parts of dibutyltin dilaurate, 2 parts of α-terpineol, 1-butyl- 0.2 parts of 3-methylimidazole chloride, 0.4 parts of carboxymethyl cellulose, and 0.4 parts of guar gum ether; the preparation method is as follows: mixing the raw materials and stirring evenly at 1000 rpm.

[0021] A preparation method for antirust paint for food production machinery adding magnetite powder, compri...

Embodiment 3

[0025] An antirust paint for food production machinery added with magnetite powder, made of the following raw materials in parts by weight: 32 parts of acrylic emulsion, 6 parts of dimethyl silicone oil, 10 parts of oxaloacetic acid, 6 parts of isocitric acid, benzoic acid ring 6 parts of hexylamine, 16 parts of boric acid, 2 parts of medical chalk, 2 parts of dibenzothiazole disulfide, 1.5 parts of catechin, 5 parts of modified magnetite powder.

[0026] The polymerized graphene oxide is made of the following raw materials in parts by weight: 10 parts of magnetite powder, 2 parts of glyceraldehyde-3-phosphate, 1 part of dibutyltin dilaurate, 3 parts of α-terpineol, 1-butyl- 0.5 part of 3-methylimidazole chloride, 0.5 part of carboxymethyl cellulose, and 0.5 part of guar gum ether; the preparation method is as follows: mixing the raw materials and stirring evenly at 1400 rpm.

[0027] A preparation method for antirust paint for food production machinery adding magnetite powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com