Method for testing content of oil sludge in phosphate fire-resistant oil

A test method and anti-fuel technology, applied in the direction of weighing by removing certain components, can solve the problems of small test results and inaccurate measurement results, and achieve the effect of improving accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

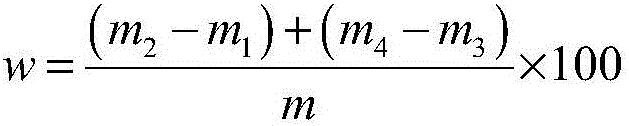

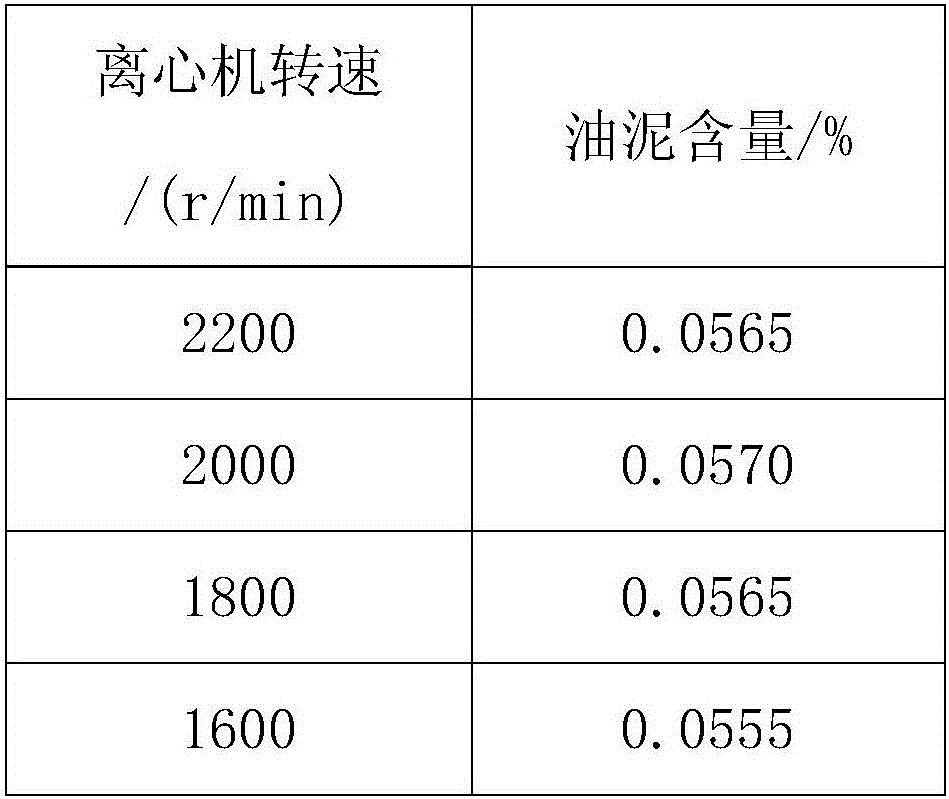

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments, and the following is an explanation rather than a limitation of the present invention.

[0025] The test method of phosphate ester anti-fuel oil sludge content of the present invention comprises the following steps:

[0026] 1) Add 20g of phosphate ester fuel oil to be tested into the centrifuge tube with constant weight, then add n-pentane to the centrifuge tube to raise the liquid level in the centrifuge tube to the 100mL mark, and then plug it tightly with the first stopper the mouth of the centrifuge tube, then shake the centrifuge tube to make the liquid in the centrifuge tube mix evenly;

[0027] 2) Open the first stopper, clean the first stopper with n-pentane, and pour the cleaning solution into the centrifuge tube, then insert the second stopper into the mouth of the centrifuge tube, wherein the second stopper is the same as the phosphate ester antibody to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com