New ionic liquid-based organic heat carrier material and preparation method thereof

A technology of ionic liquid and carrier material, which is applied in the field of ionic liquid-based organic heat carrier new materials and its preparation, can solve the problems of industrial heat transfer oil products such as environmental protection, high kinematic viscosity of heat transfer oil, poor high temperature thermal stability, etc., and achieve low price , heat conduction rate is uniform, the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

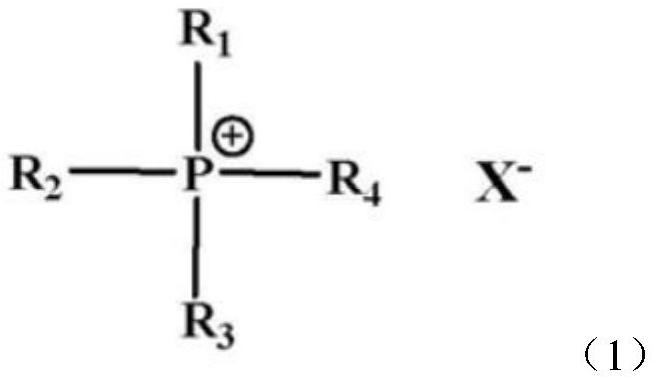

[0064] A green and environmentally friendly organic heat carrier with special high thermal stability. Take 560g of tetrabutylphosphine bis(trifluoromethanesulfonic acid)imide salt, disperse it in 2.2g of absolute ethanol and 2.6g of absolute methanol, and soak it for 5h; The obtained mixture was placed in a microwave-assisted vacuum dryer at a drying temperature of 50° C., a vacuum degree of 10,000 Pa, and a microwave treatment frequency of 30 GHz for 0.2 h to obtain an ionic liquid organic heat carrier 1 .

Embodiment 2

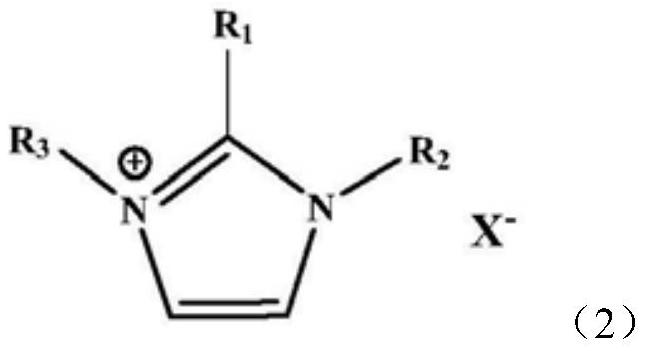

[0066] A green and environmentally friendly organic heat carrier with special high thermal stability. Take 260g of N-butylpyridine tetrafluorophosphate, disperse it into 25.5g of triethylamine, and soak it for 2h; put the obtained mixture in a microwave-assisted vacuum dryer, and dry it The temperature is 250° C., the vacuum degree is 10000 Pa, and the microwave treatment frequency is 300 MHz, and the drying treatment is performed for 0.5 h to obtain the ionic liquid organic heat carrier 2 .

Embodiment 3

[0068] A green and environmentally friendly organic heat carrier with special high thermal stability. Take 400g of trimethylimidazolium tetrafluoroborate, disperse it in 54g of xylene, and soak it for 10h; put the obtained mixture in a microwave-assisted vacuum dryer, and the drying temperature is 40° C., vacuum degree of 100 Pa, microwave treatment frequency of 10 GHz and drying treatment for 0.5 h to obtain ionic liquid organic heat carrier 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com