Liquid degradable mulching film produced by utilizing humus product as well as preparation method and application of liquid degradable mulching film

A technology for degrading plastic film and products, applied in the field of solid waste resource utilization, can solve problems such as easy cracking and poor mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

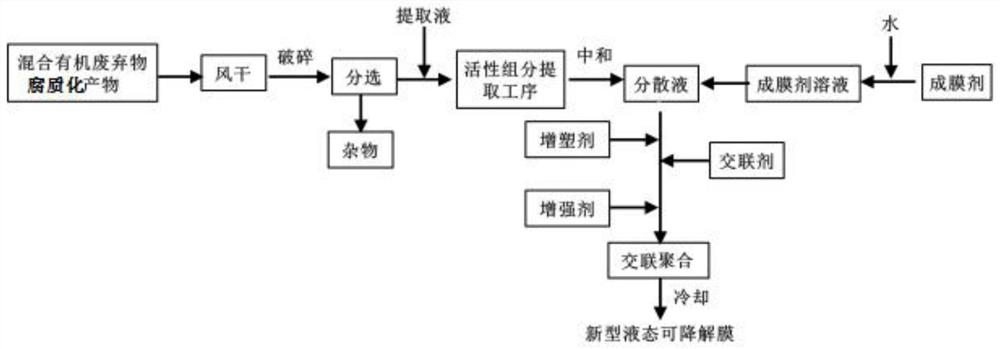

[0021] The invention provides a preparation method of a liquid degradable mulch film produced by utilizing a degraded product, comprising the following steps:

[0022] Mixing the decomposing product of rural mixed organic wastes with an alkali extractant, and extracting to obtain a dispersion;

[0023] The dispersion liquid, the film-forming agent, the plasticizer, the cross-linking agent and the reinforcing agent are mixed, and a cross-linking polymerization reaction is carried out to obtain a liquid degradable mulch film.

[0024] Unless otherwise specified, the present invention has no special requirements on the source of the raw materials used for the preparation, and commercially available products well known to those skilled in the art can be used.

[0025] In the present invention, the decomposing product of the rural mixed organic waste is mixed with an alkali extraction agent for extraction.

[0026] The present invention does not specifically limit the source of th...

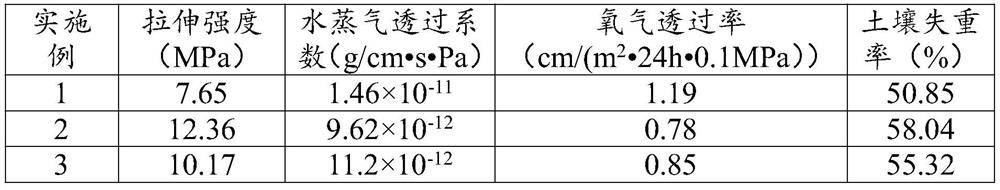

Embodiment 1

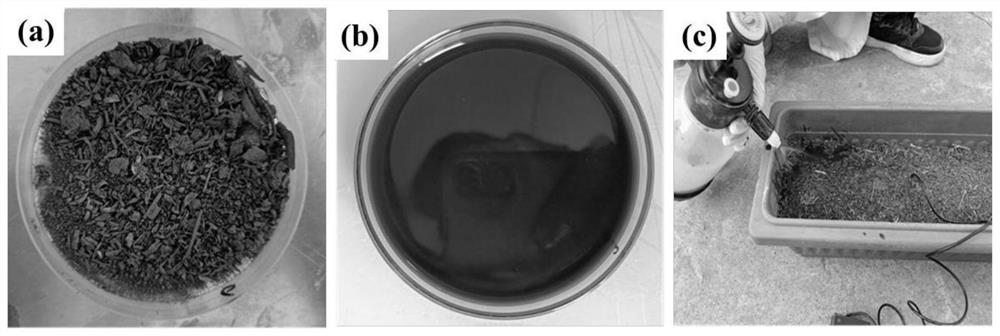

[0057] Using cow dung and wheat straw with a mass ratio of 1:1 as raw materials, fermented for 30 days under the condition of intermittent ventilation at 60°C under Gore membrane coverage to obtain the decomposing product of rural mixed organic waste;

[0058] Take 4.00g of the decomposing product of rural mixed organic waste after air-drying, mechanical sorting, impurity removal, crushing and sieving (60 mesh sieve), add 40mL, 0.01g / mL potassium hydroxide aqueous solution according to the mass ratio of 1:10 , extracted at 90°C with stirring at 400rpm for 120min, cooled to room temperature, adjusted pH to 7 with 2mol / L citric acid solution to obtain a dispersion; weighed 2.80g of sodium alginate, stirred at 400rpm at 90°C Until the sodium alginate is completely dissolved in 66mL of water, after cooling, transfer to the dispersion liquid, stir at 350rpm, add 0.93g glycerol, 0.50g glutaraldehyde, 1.10g sodium carboxymethylcellulose in sequence after 20min interval, and seal the r...

Embodiment 2

[0060] Take 4.00g of the rural mixed organic waste decomposing product (consistent with the preparation process of Example 1) after air-drying, mechanical sorting, impurity removal, crushing and sieving (60 mesh sieve), and add it in a mass ratio of 1:10. 40mL, 0.005g / mL potassium hydroxide aqueous solution, extract 150min at 90°C with stirring at 400rpm, after cooling to room temperature, adjust pH to 7 with 2mol / L citric acid solution to obtain a dispersion; Weigh 2.80g alginic acid Sodium, stir at 400 rpm at 90 °C until sodium alginate is completely dissolved in 66 mL of water, transfer to the dispersion after cooling, stir at 350 rpm, and add 0.5 g of glycerol, 2.0 g of glutaraldehyde, 1.60 g sodium carboxymethyl cellulose, sealed the reaction kettle, heated up to 90° C., carried out cross-linking polymerization reaction at 350 rpm for 2 h, and cooled at room temperature to obtain a liquid degradable plastic film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com