Method for carrying out microcontact printing by employing plane conjugate phthalocyanine-porphyrin coordination compound

A technology of micro-contact printing and planar conjugation, which is applied in the direction of printing, printing, and printing processes for the production of special types of printed matter. It can solve problems such as applications that have not been reported, and achieve the effect of easy-to-obtain raw materials, low cost, and strong stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. The base material polymethyl methacrylate was ultrasonically cleaned with ethanol for 1 hour, and then vacuum-dried at 80°C. use 60 It is irradiated with Co gamma rays, the dose is 100KGy, and the time is 150h. Put 100 g of the irradiated substrate into a three-necked bottle, add 1 g of acrylic acid and 500 ml of distilled water, and react at 80° C. for 1 hour.

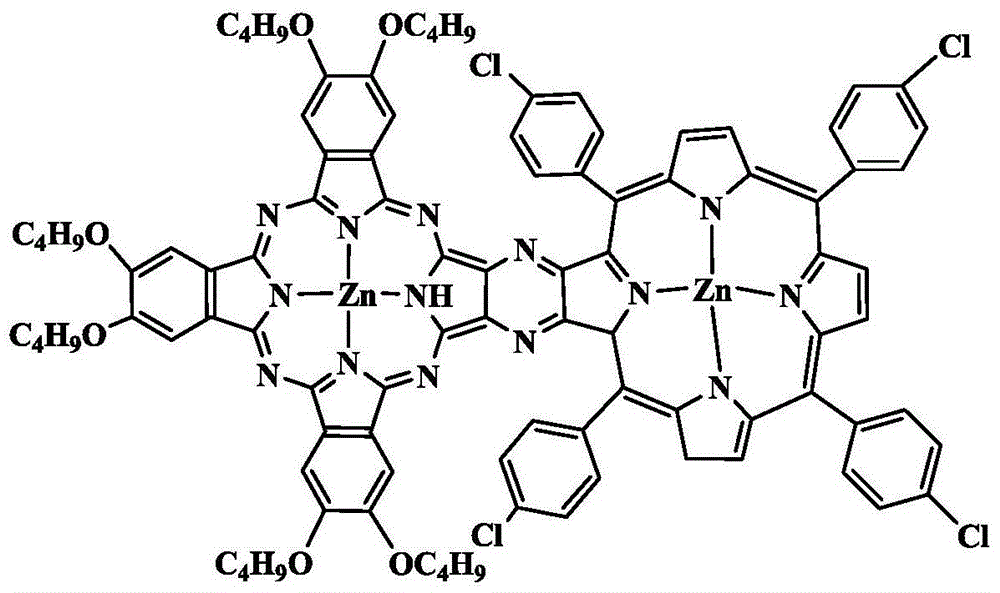

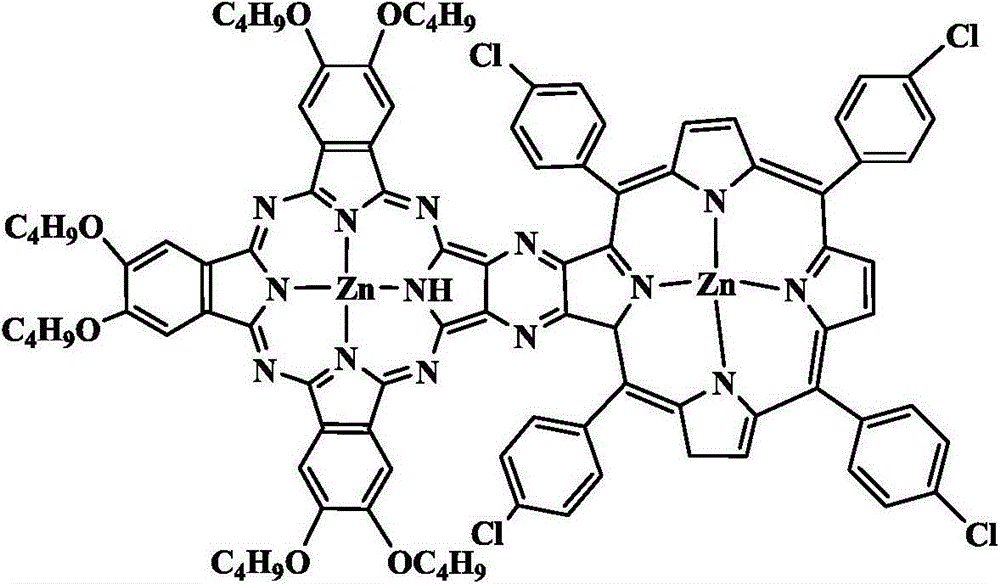

[0024] 2. Dissolve 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc in dichloromethane to obtain 5,10,15,20-p-chlorobenzene with a concentration of 1g / L porphyrin-based zinc hexabutoxyphthalocyanine zinc dichloromethane solution.

[0025] 3. Soak the PDMS stamp in 5, 10, 15, 20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution for 1 minute, take it out and put it in N 2 Dry in airflow for 30s, cover the PDMS stamp coated with 5,10,15,20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution on the carboxylation substra...

Embodiment 2

[0028] 1. The base material polymethyl methacrylate was ultrasonically cleaned with ethanol for 1 hour, and then vacuum-dried at 80°C. use 60 It is irradiated with Co gamma rays, the dose is 125KGy, and the time is 160h. Put 100 g of the irradiated substrate into a three-necked bottle, add 1 g of acrylic acid and 500 ml of distilled water, and react at 80° C. for 1 hour.

[0029] 2. Dissolve 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc with dichloromethane to obtain 5,10,15,20-p-chlorobenzene with a concentration of 5g / L porphyrin-based zinc hexabutoxyphthalocyanine zinc dichloromethane solution.

[0030] 3. Soak the PDMS stamp in 5, 10, 15, 20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution for 1-2 minutes, take it out and put it in N 2 Dry in airflow for 50s, cover the PDMS stamp coated with 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc dichloromethane solution on the carboxylatio...

Embodiment 3

[0033] 1. The base material polymethyl methacrylate was ultrasonically cleaned with ethanol for 1 hour, and then vacuum-dried at 80°C. use 60 It is irradiated with Co gamma rays, the dose is 150KGy, and the time is 180h. Put 100 g of the irradiated substrate into a three-necked bottle, add 1 g of acrylic acid and 500 ml of distilled water, and react at 80° C. for 1 hour.

[0034] 2. Dissolve 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc with dichloromethane to obtain 5,10,15,20-p-chlorobenzene with a concentration of 10g / L porphyrin-based zinc hexabutoxyphthalocyanine zinc dichloromethane solution.

[0035] 3. Soak the PDMS stamp in 5, 10, 15, 20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution for 1-2 minutes, take it out and put it in N 2 Dry in airflow for 60s, cover the PDMS stamp coated with 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc dichloromethane solution on the carboxylati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com