Production technology of PVC external lubricant

A production process and external lubricant technology, applied in the field of plastics, can solve the problems of high labor intensity, high processing temperature, low production efficiency, etc., and achieve the effects of improving product quality, reducing reaction temperature and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

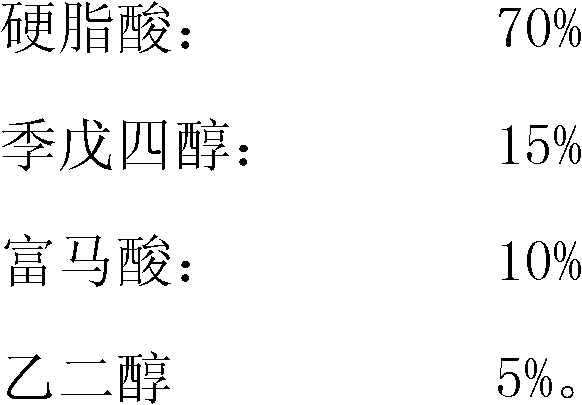

Embodiment 1

[0047] Fumaric acid is acid reflux obtained by recycling waste liquid produced by other chemical industries. The standard chemical name of fumaric acid is: fumaric acid; molecular formula is: C 4 h 4 o 4 ; It is a white crystalline powder with a fruity sour taste.

[0048] The process of recovering fumaric acid in the process of producing phthalic anhydride by ortho-method is as follows: the oxidation tail gas of phthalic anhydride produced by ortho-method is washed with water, contains 25%wt cisic acid, and is directly pumped to the fumaric acid production device. Under the action of a catalyst, the cis acid in the waste liquid is isomerized, the catalyst is selected from thiourea, the acid reflux is recovered, and fumaric acid (fumaric acid) is obtained by crystallization. Because the acid water is brown, the crude fumaric acid after cooling and crystallization is brown, decolorized with activated carbon, rinsed and dried to obtain refined fumaric acid.

[0049] During p...

Embodiment 2

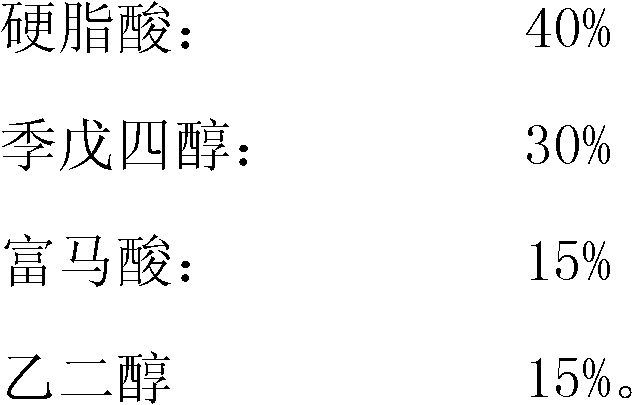

[0057] The mass percent of each component is:

[0058] Stearic acid: 40%

[0059] Pentaerythritol: 30%

[0060] Fumaric Acid: 15%

[0061] Ethylene glycol 15%

[0062] Composition, in which fumaric acid is extracted from gutter oil after filtering. During processing, fumaric acid is selected as the mother liquor in proportion, and then ethylene glycol is added in proportion. Stearic acid is added for esterification, followed by high-temperature polymerization at 150°C. After polymerization, dealcoholization is carried out under high-temperature vacuum at 200°C, and sliced after cooling. No catalyst is added during the entire process. The conversion of this reaction is around 94%.

[0063] The appearance of the obtained PVC external lubricant and its manufacturing process is white or light yellow flake or flake powder, with a freezing point of ≥ 56°C, a flash point of ≥ 240°C, and a viscosity of ≤ 90mpa·S at 80°C. When adding PVC raw materials, the general dosage is 0.3%-0...

Embodiment 3

[0065] The mass percent of each component is:

[0066] Stearic acid: 40%

[0067] Pentaerythritol: 20%

[0068] Fumaric Acid: 23%

[0069] Dipropylene Glycol 17%

[0070] Composition, in which fumaric acid is extracted from gutter oil after filtering, first select fumaric acid as the mother liquor in proportion during processing, then first add dipropylene glycol in proportion, after fully stirring, add pentaerythritol according to the above proportion, and finally add Stearic acid is esterified, then polymerized at a high temperature of 150°C, dealcoholized in a vacuum at a high temperature of 200°C after polymerization, sliced after cooling, and no catalyst is added during the whole process. The conversion of this reaction is around 95%.

[0071] The appearance of the obtained PVC external lubricant and its manufacturing process is white or light yellow flake or flake powder, with a freezing point of ≥ 56°C, a flash point of ≥ 240°C, and a viscosity of ≤ 90mpa·S at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com