Combined type magnetic frame

A magnetic frame and combined technology, applied in the field of magnetic frames, can solve the problems of loss of magnetic beads, unoptimized shape and position of magnets, inseparability, etc. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

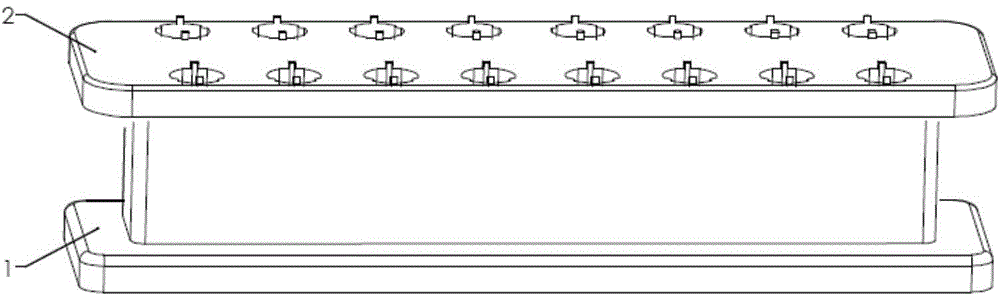

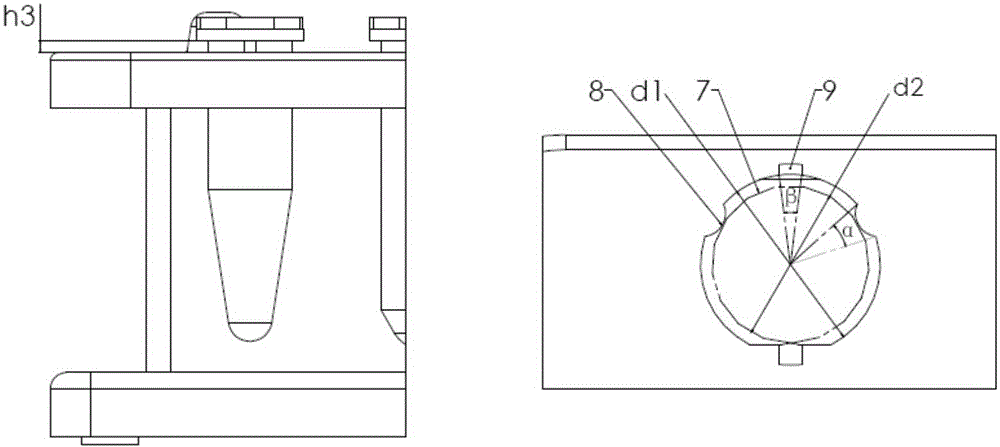

[0030] like figure 1 and figure 2 As shown, the magnetic frame includes a separable and combined magnet frame 1 and a micro test tube frame 2; the magnet frame 1 is mainly composed of a magnet frame base 3 and a column part 4 which is vertically fixed on the magnet frame base 3 and is provided with a magnet. The micro test tube rack 2 is mainly composed of a micro test tube rack flat plate 5 and a column part 6 with a cavity structure vertically fixed on the micro test tube rack flat plate 5 lower ends; the column part 6 with a cavity structure is vertically fixed on the magnet The cylinder part 4 that is provided with the magnet on the frame base 3 is matched to realize the separation and combination of the magnet frame 1 and the micro test tube frame 2; the column part 6 with the cavity structure can also be used as the micro test tube frame 2 The base; the thickness (h) of the micro test tube rack plate 5 is 7mm, and there are micro test tube holes 7 for placing micro tes...

Embodiment 2

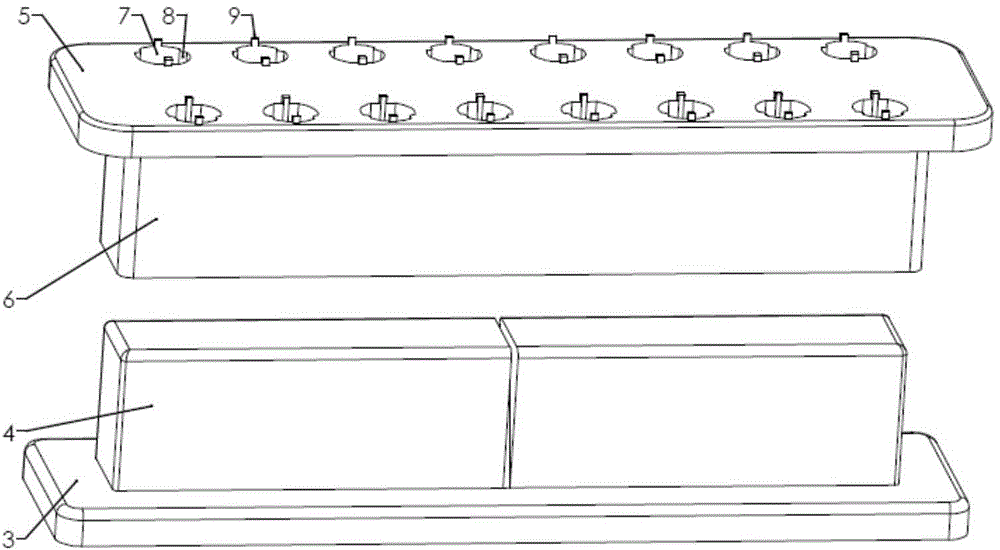

[0034] like Image 6 and Figure 7 As shown, the magnetic frame includes a separable and combined magnet frame 1 and a micro test tube frame 2; the magnet frame 1 is mainly composed of a magnet frame base 3 and a column part 4 which is vertically fixed on the magnet frame base 3 and is provided with a magnet. The micro test tube rack 2 is mainly composed of a micro test tube rack flat plate 5 and a column part 6 with a cavity structure vertically fixed on the micro test tube rack flat plate 5 lower ends; the column part 6 with a cavity structure is vertically fixed on the magnet The cylinder part 4 that is provided with the magnet on the frame base 3 is matched to realize the separation and combination of the magnet frame 1 and the micro test tube frame 2; and the column part 6 with the cavity structure can also be used as a micro test tube frame The base of 2; the thickness (h) of described micro test tube rack flat plate 5 is 1-15mm, has the micro test tube hole 7 that is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com