Sound insulating PVB (polyvinyl butyral) laminated glass and preparation method thereof

A technology of laminated glass and glass substrate, applied in chemical instruments and methods, glass/slag layered products, lamination, etc., can solve the problems affecting the service life of PVB soundproof glass, different thermal expansion coefficients, and film mechanical properties. , to achieve the effect of good mechanical properties, less internal voids, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

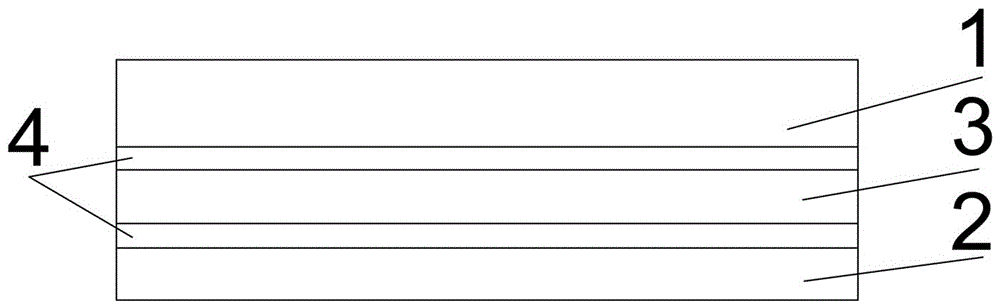

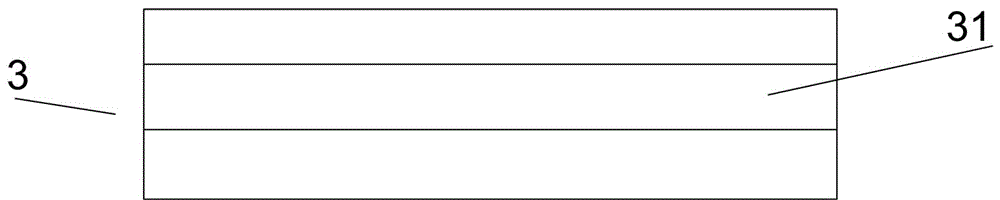

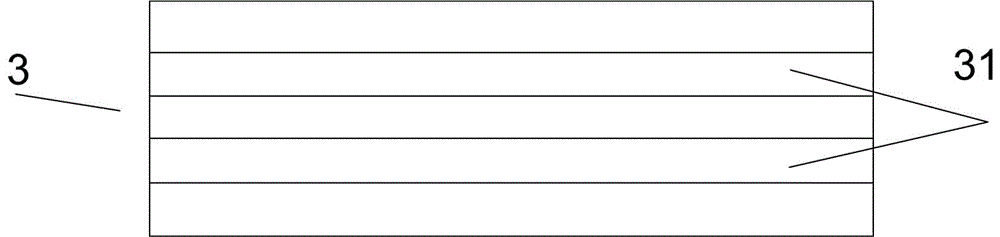

[0046] like figure 1 , 2 Schematic diagram of the structure of PVB glass and PVB film shown. A PVB sound-insulating laminated glass, including a first glass substrate 1 and a second glass substrate 2 arranged up and down, a PVB film 3 between the first glass substrate and the second glass substrate, and a The polystyrene film 4 between the substrate and the PVB film, the second glass substrate and the PVB film. The PVB film is composed of three layers of PVB films. The middle layer of PVB film is a cross-linkable PVB film 31 made of cross-linkable PVB resin. The outer layers on both sides are PVB films made of polyvinyl butyral resin. Layer cross-linkable PVB resin structure is:

[0047]

[0048] The preparation method of the above-mentioned PVB sound-insulating laminated glass is as follows:

[0049](1) Cleaning of the glass substrate: clean the oil stains, dust and other impurities on the surface of the selected glass substrate, and dry it for later use;

[0050] (2)...

Embodiment 2

[0061] A PVB sound-insulating laminated glass, including a first glass substrate 1 and a second glass substrate 2 arranged up and down, a PVB film 3 between the first glass substrate and the second glass substrate, and a The polystyrene film 4 between the substrate and the PVB film, the second glass substrate and the PVB film. The PVB film is composed of three layers of PVB films. The middle layer of PVB film is a cross-linkable PVB film 31 made of cross-linkable PVB resin. The outer layers on both sides are PVB films made of polyvinyl butyral resin. Layer cross-linkable PVB resin structure is:

[0062]

[0063] The preparation method of the above-mentioned PVB sound-insulating laminated glass is as follows: the same as in Example 1, the difference lies in the preparation of the polystyrene film in step (2): the weight ratio is:

[0064] 95 parts polystyrene

[0065] Antioxidant 0.5 parts

[0066] 38 parts of SEBS block copolymer

[0067] EBS 0.6 copies

[0068] Modifi...

Embodiment 3

[0071] A PVB sound-insulating laminated glass, including a first glass substrate 1 and a second glass substrate 2 arranged up and down, a PVB film 3 between the first glass substrate and the second glass substrate, and a The polystyrene film 4 between the substrate and the PVB film, the second glass substrate and the PVB film. The PVB film is composed of three layers of PVB films. The middle layer of PVB film is a cross-linkable PVB film 31 made of cross-linkable PVB resin. The outer layers on both sides are PVB films made of polyvinyl butyral resin. Layer cross-linkable PVB resin structure is:

[0072]

[0073] The preparation method of the above-mentioned PVB sound-insulating laminated glass is as follows: the same as in Example 1, the difference lies in the preparation of the polystyrene film in step (2): the weight ratio is:

[0074] Polystyrene 100 parts

[0075] Antioxidant 0.6 parts

[0076] SEBS block copolymer 40 parts

[0077] EBS 0.8 copies

[0078] Modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com