Construction technology of soundproof inner wall

A construction technique and interior wall technology, applied in the direction of sound insulation, insulation layer, building components, etc., can solve the problems that affect the toughness of the coating film, the coating film is easy to crack, and limit the sound insulation performance, so as to improve the toughness of the sound insulation coating, easy to disperse, Make up for the effect of poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

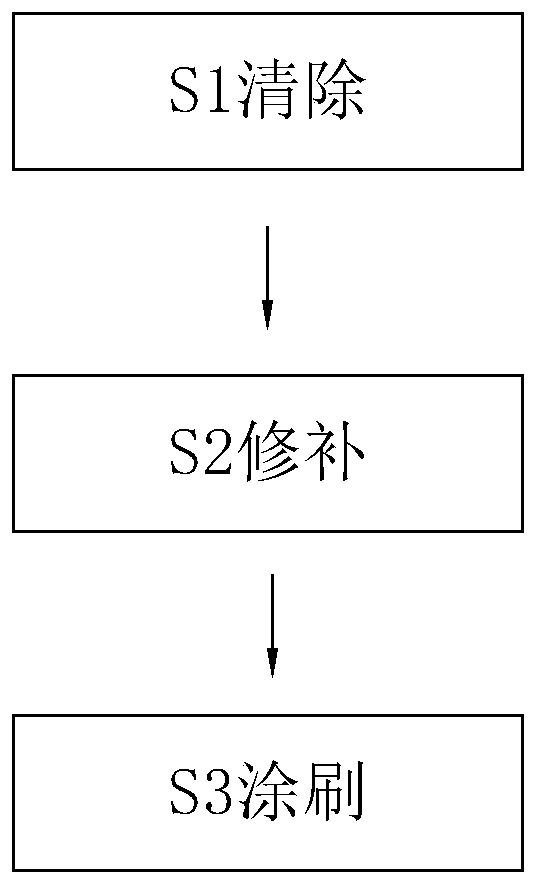

[0050] A construction technique for soundproof interior walls, such as figure 1 shown, including the following steps:

[0051] S1 Clearing: Remove all the plaster layer on the inner surface of the original wall, and then apply the interface agent on the wall;

[0052] S2 Repair: Next, paste white adhesive stickers on the cracks of the inner wall, then lay mesh cloth on the entire inner wall, and brush cement mortar until the wall is smooth;

[0053] S3 painting: first brush one layer of base layer putty, then brush two layers of putty, after polishing, brush a layer of anti-alkali primer, then brush three layers of sound insulation paint, each layer of sound insulation paint is 1mm thick, and wait for the last layer of sound insulation paint to dry for 12 hours Finally, a layer of painting is carried out to form a sound insulation coating, and finally two layers of latex topcoat are applied.

Embodiment 2

[0055] The soundproof coating comprises the following components by weight:

[0056] 35 parts of water-based epoxy resin emulsion, the trade mark is GEM02, purchased from Shanghai Lvjia Water-based Paint Co., Ltd.;

[0057] 15 parts of methyl hexahydrophthalic anhydride;

[0058] 40 parts of rubber modified nano inorganic fillers;

[0059] 5 parts of maleic anhydride;

[0060] Montmorillonite 3 parts, particle size 25μm;

[0061] 5 parts of mica powder, particle size 10μm;

[0062] 0.15 parts of acrylate leveling agent, brand LD-9601, purchased from Yangzhou Lida Resin Co., Ltd.;

[0063] OP-10 0.3 parts;

[0064] 0.1 parts of silicone defoamer, brand LD-200, purchased from Yangzhou Lida Resin Co., Ltd.;

[0065] 15 parts of water.

[0066] The nano-inorganic filler is composed of nano-silica, nano-calcium carbonate, carbon nanotubes and hollow glass microspheres with a mass ratio of 5:3:1:1. The particle size of the nano-silica is 25nm, the particle size of the nano-cal...

Embodiment 3

[0077] The soundproof coating comprises the following components by weight:

[0078] 40 parts of water-based epoxy resin emulsion, the trade mark is GEM02, purchased from Shanghai Lvjia Water-based Paint Co., Ltd.;

[0079] 20 parts of methyl hexahydrophthalic anhydride;

[0080] 45 parts of rubber modified nano inorganic fillers;

[0081] 8 parts of maleic anhydride;

[0082] Montmorillonite 5 parts, particle size 25μm;

[0083] 8 parts of mica powder, particle size 10μm;

[0084] 0.3 parts of acrylate leveling agent, brand LD-9601, purchased from Yangzhou Lida Resin Co., Ltd.;

[0085] OP-10 0.5 parts;

[0086] 0.2 parts of silicone defoamer, brand LD-200, purchased from Yangzhou Lida Resin Co., Ltd.;

[0087] 20 parts of water.

[0088] The nano-inorganic filler is composed of nano-silica, nano-calcium carbonate, carbon nanotubes and hollow glass microspheres with a mass ratio of 5:3:1:1. The particle size of the nano-silica is 25nm, the particle size of the nano-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com