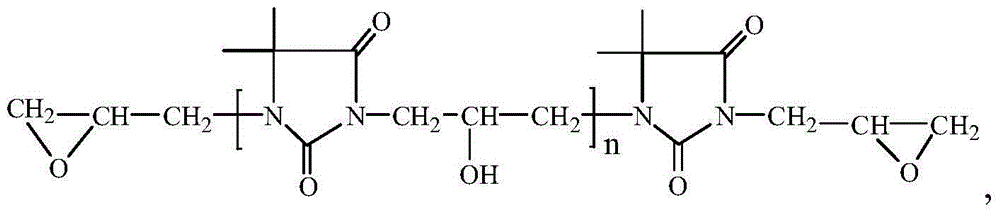

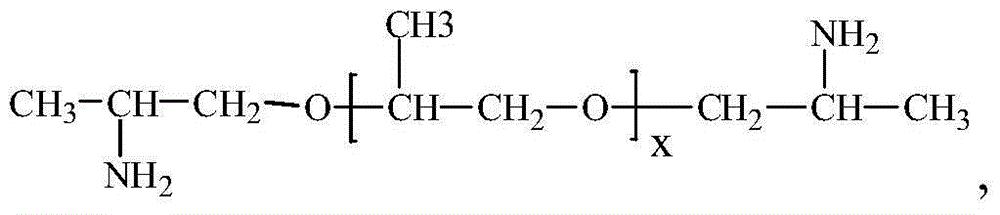

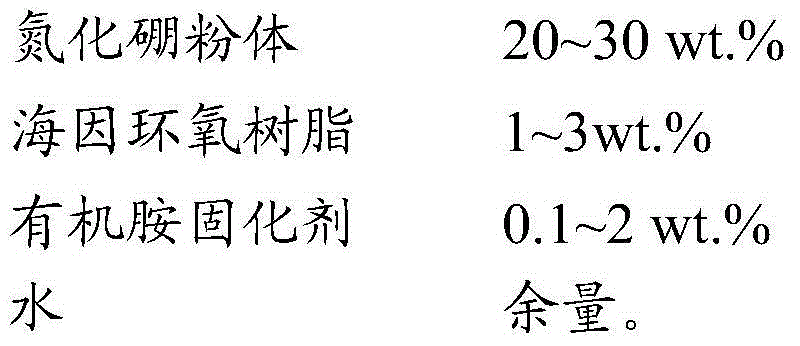

Surface-organically-modified boron nitride powder, preparation method and applications thereof

A technology of boron nitride powder and boron nitride, which is applied in the application field of preparing thermally conductive polymers, can solve the problems of stronger force, unfavorable powder uniform dispersion and mixed glue fluidity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In a 1000ml three-necked flask, 200g of deionized water, 100g of boron nitride powder (purchased from Liaobin Fine Chemical Co., Ltd. Huilong Electronic Materials Co., Ltd., epoxy value 0.70mol / 100g) 2g, put the flask in a heating mantle, heat while stirring until the temperature rises to 30°C, keep stirring at this temperature for 20min; then, under stirring, The aqueous solution of diethylenetriamine (2.8g is dissolved in 25g deionized water) and the aqueous solution of hydantoin epoxy resin (6g is dissolved in 25g deionized water) are started dropwise respectively in the flask, and the rate of addition is about 1.5 ml / min , continue to stir for 90min after the dropwise addition is completed; filter the mixture with a Buchner funnel (200mm), rinse the powder with deionized water (500ml×3), then place the powder in a blast oven at 100°C for 5 hours, collect The dried powder is ready for use. The contact angles of the obtained powders are shown in Table 1.

Embodiment 2

[0068]In a 1000ml three-necked flask, 250g of deionized water, 100g of boron nitride powder (purchased from Liaobin Fine Chemical Co., Ltd. Huilong Electronic Materials Co., Ltd., epoxy value 0.70mol / 100g) 1g, put the flask in a heating mantle, heat while stirring until the temperature rises to 40°C, keep stirring at this temperature for 20min; then, under stirring, The aqueous solution of triethylenetetramine (3.5g is dissolved in 25g deionized water) and the aqueous solution of hydantoin epoxy resin (6g is dissolved in 25g deionized water) are started dropwise respectively in the flask, and the rate of addition is about 1.0 ml / min , continue to stir for 90min after the dropwise addition is completed; filter the mixture with a Buchner funnel (200mm), rinse the powder with deionized water (500ml×3), then place the powder in a blast oven at 100°C for 5 hours, collect The dried powder is ready for use. The contact angles of the obtained powders are shown in Table 1.

Embodiment 3

[0070] 170g of deionized water, 100g of boron nitride powder (purchased from Liaobin Fine Chemical Co., Ltd., Yingkou, Liaoning Province, median particle size 100 μm) and 1070 hydantoin epoxy resin (purchased from Wuxi, Jiangsu Province) were added to a 1000ml three-necked flask. Huilong Electronic Materials Co., Ltd., epoxy value 0.70mol / 100g) 1g, put the flask in a heating mantle, heat while stirring until the temperature rises to 40°C, keep stirring at this temperature for 20min; then, under stirring, The aqueous solution of pentaethylenehexamine (0.75g dissolved in 25g deionized water) and hydantoin epoxy resin aqueous solution (4g dissolved in 25g deionized water) were added dropwise to the flask respectively at a rate of about 1.0 ml / min , continue to stir for 90min after the dropwise addition is completed; filter the mixture with a Buchner funnel (200mm), rinse the powder with deionized water (500ml×3), then place the powder in a blast oven at 100°C for 5 hours, collect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com