Phase change gypsum board for construction

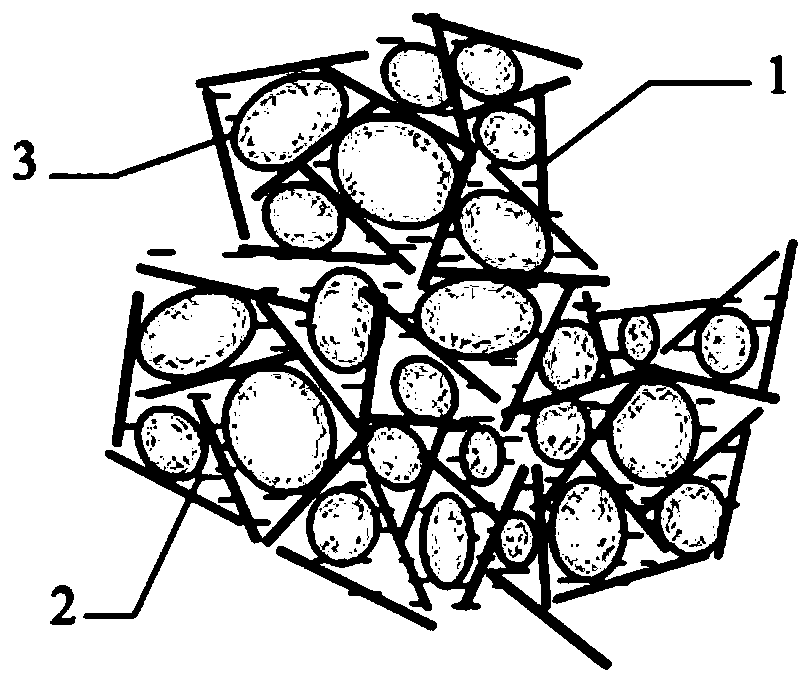

A technology for gypsum board and construction, applied in the direction of building components, paper/cardboard layered products, layered products, etc., can solve the problem of low energy storage density, poor thermal conductivity, and reduce the heat storage density and thermal performance of phase change materials and other problems, to achieve the effect of large heat storage capacity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

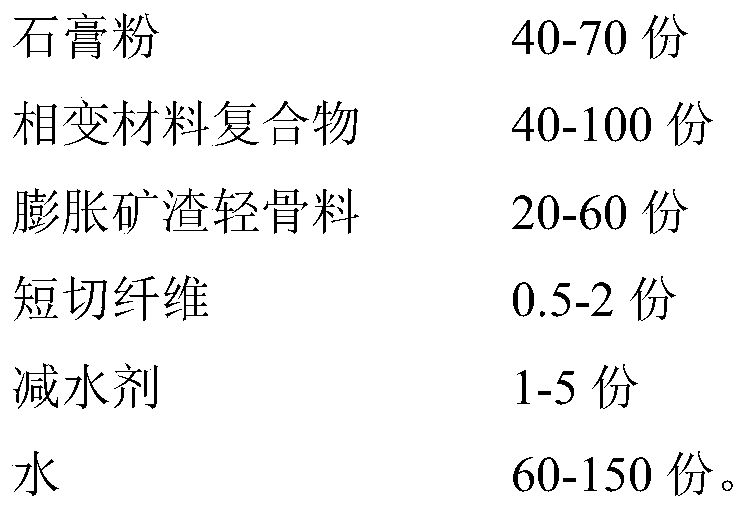

[0042] A phase-change gypsum board for construction, comprising the following components in parts by weight:

[0043]

[0044] The phase-change material composite includes the following components in parts by weight: 110 parts of phase-change material, 40 parts of montmorillonite, and 300 parts of water. Wherein said phase change material is 70 parts of n-octadecane, 40 parts of 52# paraffin.

[0045] The phase change material composite, its preparation process, comprises the following steps:

[0046] (1) Weigh each component according to the formula amount, disperse montmorillonite in deionized water in a 1000mL beaker, stir, then use a high-shear mixing emulsifier to stir for 30 minutes at 2500 rpm to disperse, and make Aqueous dispersion of montmorillonite;

[0047] (2) In a 500mL beaker, n-octadecane and 52# paraffin are heated to complete melting to obtain a molten phase-change material;

[0048](3) The molten phase-change material prepared by step (2) is added to t...

Embodiment 2

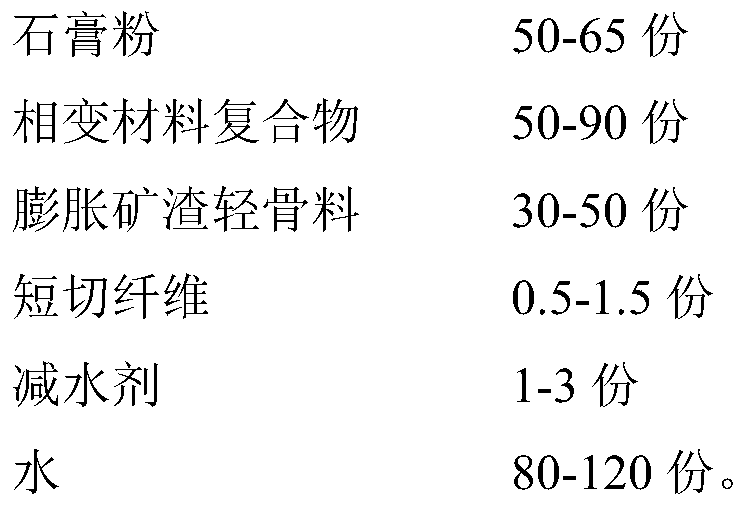

[0057] A phase-change gypsum board for construction, comprising the following components in parts by weight:

[0058]

[0059] The phase-change material composite includes the following components in parts by weight: 90 parts of phase-change material, 20 parts of kaolin, and 100 parts of water. Wherein the phase change material includes aliphatic hydrocarbon compound and alcohol compound; the aliphatic hydrocarbon compound is 20 parts of n-eicosane; and the alcohol compound is 70 parts of lauryl alcohol.

[0060] The phase change material composite, its preparation process, comprises the following steps:

[0061] (1) Take each component according to the formula quantity, stir kaolin in deionized water in a 1000mL beaker, then use a high-shear mixing emulsifier to disperse at 2500 rpm for 30 minutes to make an aqueous dispersion of kaolin ;

[0062] (2) In a 500mL beaker, the phase change material is heated to complete melting to obtain a molten phase change material;

[...

Embodiment 3

[0072] A phase-change gypsum board for construction, comprising the following components in parts by weight:

[0073]

[0074] The phase change material composite includes the following components in parts by weight: 110 parts of phase change material, 30 parts of bentonite, and 240 parts of deionized water. Wherein the phase change material includes alcohol compounds and ester compounds; the alcohol compounds are 40 parts of neopentyl glycol; the ester compounds are 70 parts of n-butyl stearate.

[0075] The phase change material composite, its preparation process, comprises the following steps:

[0076] (1) Take each component by formula quantity, in 1000mL beaker, kaolin is dispersed in water with a high-shear mixing emulsifier at 2500 rpm for 30 minutes to make an aqueous dispersion of kaolin;

[0077] (2) In a 500mL beaker, the phase change material is heated to complete melting to obtain a molten phase change material;

[0078] (3) Add the molten phase-change materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com