Warm-mix modifier and preparation method thereof

A modifier and warm mix technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of low temperature performance damage of asphalt mixture, reduced water damage resistance performance of pavement, and reduced low temperature ductility of asphalt. Mixing temperature and properties are uniform, and the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

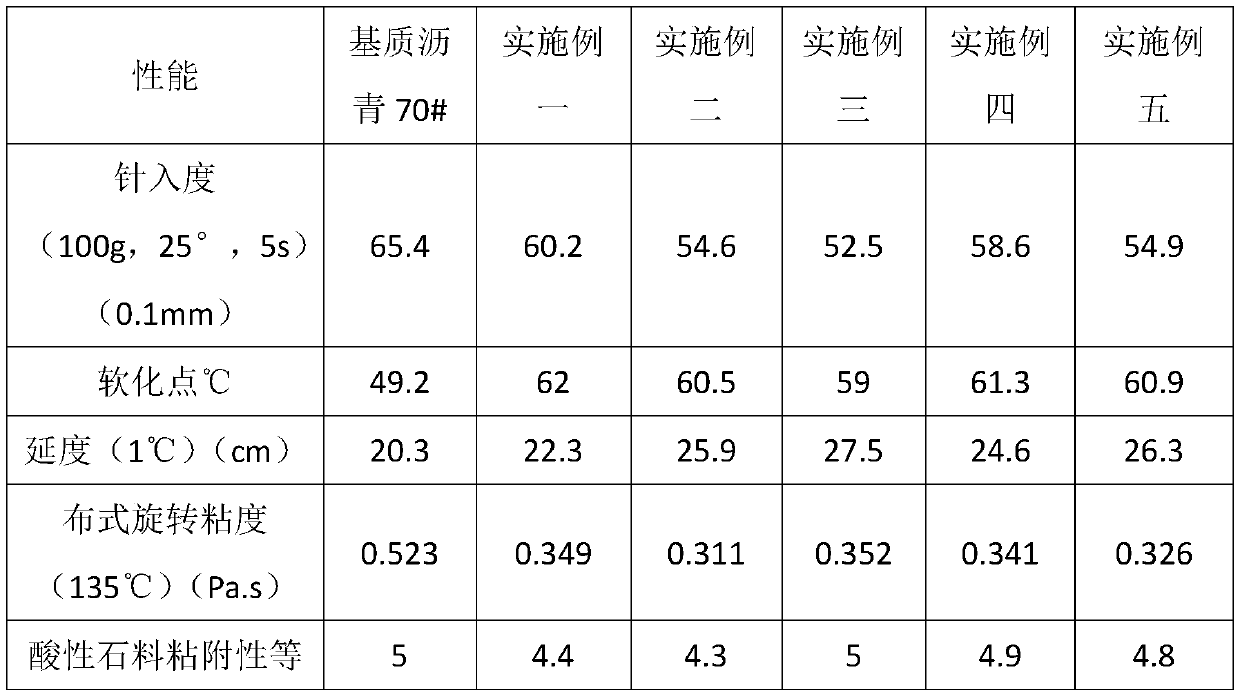

[0041] A warm mixing modifier, raw materials include the following components by weight: 25 parts of N,N,-ethylenebisstearamide, 18 parts of n-butyl stearate, ethyl cellulose (ethoxylated The weight part content is 46%) 16 parts, aromatic hydrocarbon oil compatibilizer 15 parts, toughening agent 12 parts.

[0042] in:

[0043] The toughening agent raw material includes the following components: 20 parts of epoxy resin, 5 parts of liquid polysulfide rubber, and 18 parts of nanometer calcium carbonate.

[0044] The epoxy resin is epoxy novolac.

[0045] The raw material of the aromatic hydrocarbon oil compatibilizer comprises the following components by weight: 10 parts in equal parts of benzene and toluene in total, and 12 parts of maleic anhydride grafted polyethylene.

Embodiment 2

[0047] A warm mixing modifier, raw materials include the following components by weight: 35 parts of N,N,-ethylenebisstearamide, 26 parts of n-butyl stearate, ethyl cellulose (ethoxylated The weight part content is 46%) 17 parts, aromatic oil compatibilizer 28 parts, toughening agent 20 parts.

[0048] in:

[0049] The raw materials of the toughening agent include the following components: 25 parts of epoxy resin, 8 parts of liquid polysulfide rubber, and 26 parts of nanometer calcium carbonate.

[0050] The epoxy resin is epoxy novolac.

[0051] The raw material of the aromatic hydrocarbon oil compatibilizer comprises the following components by weight: 15 parts of benzene and 25 parts of maleic anhydride grafted polyethylene.

Embodiment 3

[0053] A warm mixing modifier, raw materials include the following components by weight: 42 parts of N,N,-ethylenebisstearamide, 25 parts of n-butyl stearate, (the content of ethoxylate by weight is 47%) 28 parts of ethyl cellulose, 30 parts of aromatic oil compatibilizer, 23 parts of toughening agent.

[0054] in:

[0055] The toughening agent raw material includes the following components: 28 parts of epoxy resin, 12 parts of liquid polysulfide rubber, and 28 parts of nanometer calcium carbonate.

[0056] The epoxy resin is epoxy novolac.

[0057] The aromatic hydrocarbon oil compatibilizer raw material comprises the following components by weight: 20 parts of toluene and xylene in equal weight parts, 28 parts of maleic anhydride grafted polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com