Polystyrene transparent color master batch and preparation method thereof

A polystyrene and manufacturing method technology, applied in the field of color masterbatch, can solve the problems of brittle and easy to crack, low impact strength, etc., achieve high transparency, good elasticity, and improve the effect of plasticizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

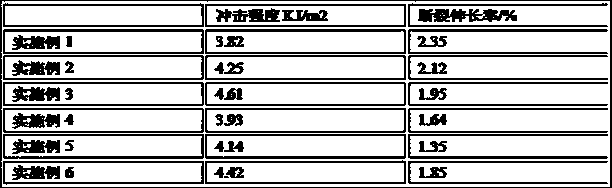

Examples

Embodiment 1

[0038] Embodiment 1, a kind of manufacture method of polystyrene transparent color masterbatch, comprises the following steps:

[0039] S01: Weigh the following raw materials in mass percentage, 40Kg polystyrene resin, 10Kg lithopone, 8Kg polyethylene wax, 0.5Kg turpentine, 1Kg azodicarbonamide, 2Kg pentaerythritol ester, 2Kg calcium stearate, 0.5Kg stearin Butyl acid;

[0040] S02: Add the polystyrene resin, colorant and turpentine in the above proportions into the high and low speed mixer in sequence, and stir until uniform. 120°C; when the stirring is completed, vacuum pump the materials in the high and low speed mixer until the turpentine volatilizes;

[0041] S03: Add polyethylene wax, azodicarbonamide, pentaerythritol ester, calcium stearate and n-butyl stearate in the above ratio into the mixer and mix and stir until uniform; wherein, the speed of the mixer is 1000rad / min, the stirring time is 15min, and the stirring temperature is 160°C;

[0042] S04: Add the mixtur...

Embodiment 2

[0043] Embodiment 2, a kind of manufacture method of polystyrene transparent color masterbatch, comprises the following steps:

[0044] S01: Weigh the following raw materials in mass percentage, 50Kg polystyrene resin, 20Kg Windsor red, 15Kg polyethylene wax, 1Kg turpentine, 5Kg azodicarbonamide, 6Kg pentaerythritol ester, 6Kg calcium stearate, 1Kg n-butyl stearate ester;

[0045] S02: Add the polystyrene resin, colorant and turpentine in the above proportions to the high and low speed mixer in sequence, and stir until uniform. 140°C; when the stirring is completed, vacuum pump the materials in the high and low speed mixer until the turpentine volatilizes;

[0046] S03: Add polyethylene wax, azodicarbonamide, pentaerythritol ester, calcium stearate and n-butyl stearate in the above ratio into the mixer and mix and stir until uniform; wherein, the speed of the mixer is 1500rad / min, the stirring time is 20min, and the stirring temperature is 180°C;

[0047] S04: Add the mixtu...

Embodiment 3

[0048] Embodiment 3, a kind of manufacture method of polystyrene transparent color masterbatch, comprises the following steps:

[0049] S01: Weigh the following raw materials in mass percentage, 43Kg polystyrene resin, 15Kg Windsor blue, 10Kg polyethylene wax, 0.8Kg turpentine, 4Kg azodicarbonamide, 4Kg pentaerythritol ester, 4Kg calcium stearate, 0.8Kg stearic acid n-butyl ester;

[0050] S02: Add the polystyrene resin, colorant and turpentine in the above proportions into the high and low speed mixer in sequence, and stir until uniform. 130°C; when the stirring is completed, vacuum pump the materials in the high and low speed mixer until the turpentine volatilizes;

[0051] S03: Add polyethylene wax, azodicarbonamide, pentaerythritol ester, calcium stearate and n-butyl stearate in the above ratio into the mixer and mix and stir until uniform; wherein, the speed of the mixer is 1200rad / min, the stirring time is 18min, and the stirring temperature is 160°C;

[0052] S04: Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com